Self-excitation aspiration pulse jet nozzle

A pulse-jet and air-breathing technology, which is applied in the direction of injection devices, liquid injection devices, earth movers/shovels, etc., can solve the problem of difficult suspension and long-distance transportation of sediment, low air content, and sediment deposition in deep water reservoirs. Efficiently deal with unfavorable problems and achieve the effect of increasing the suspension height and conveying distance, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with example (accompanying drawing):

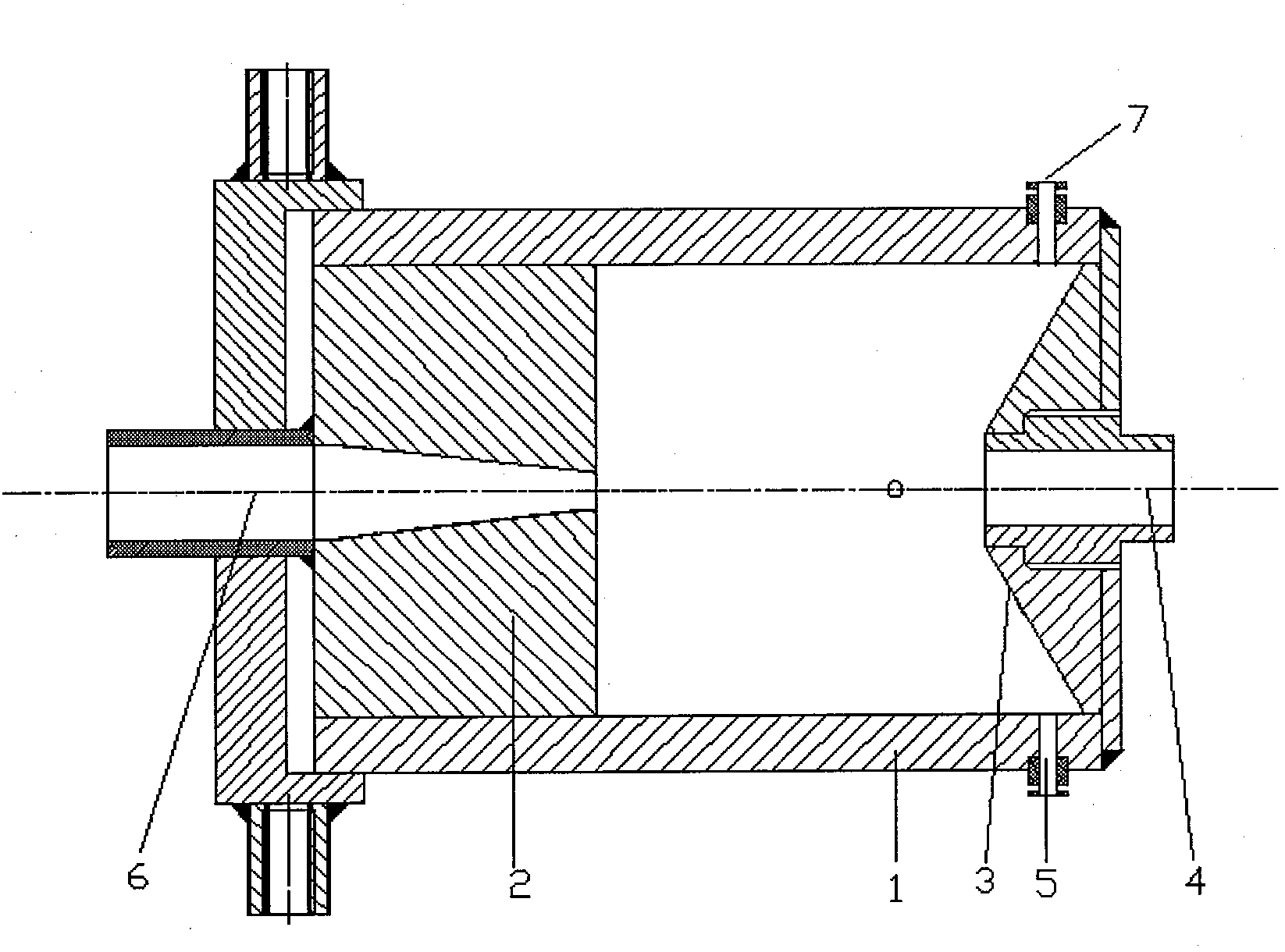

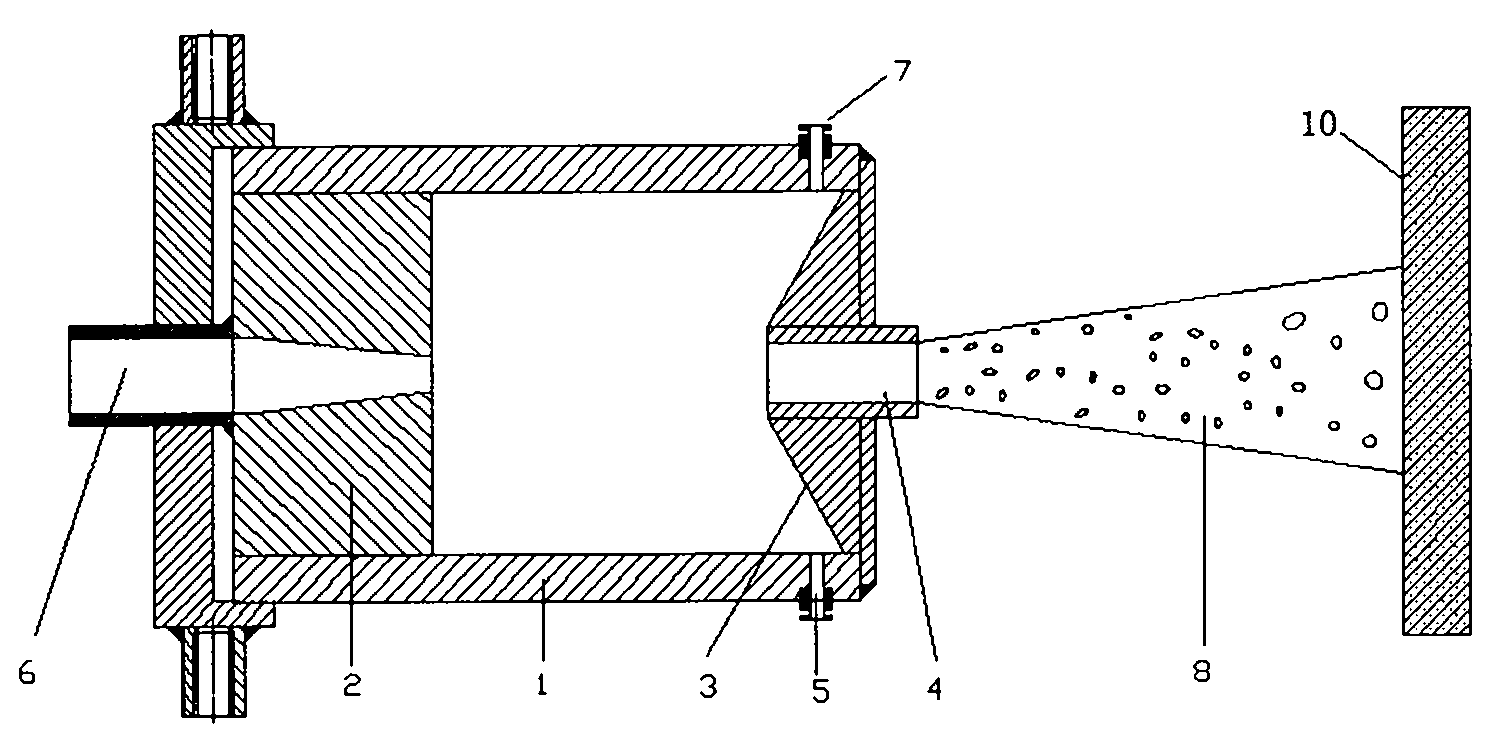

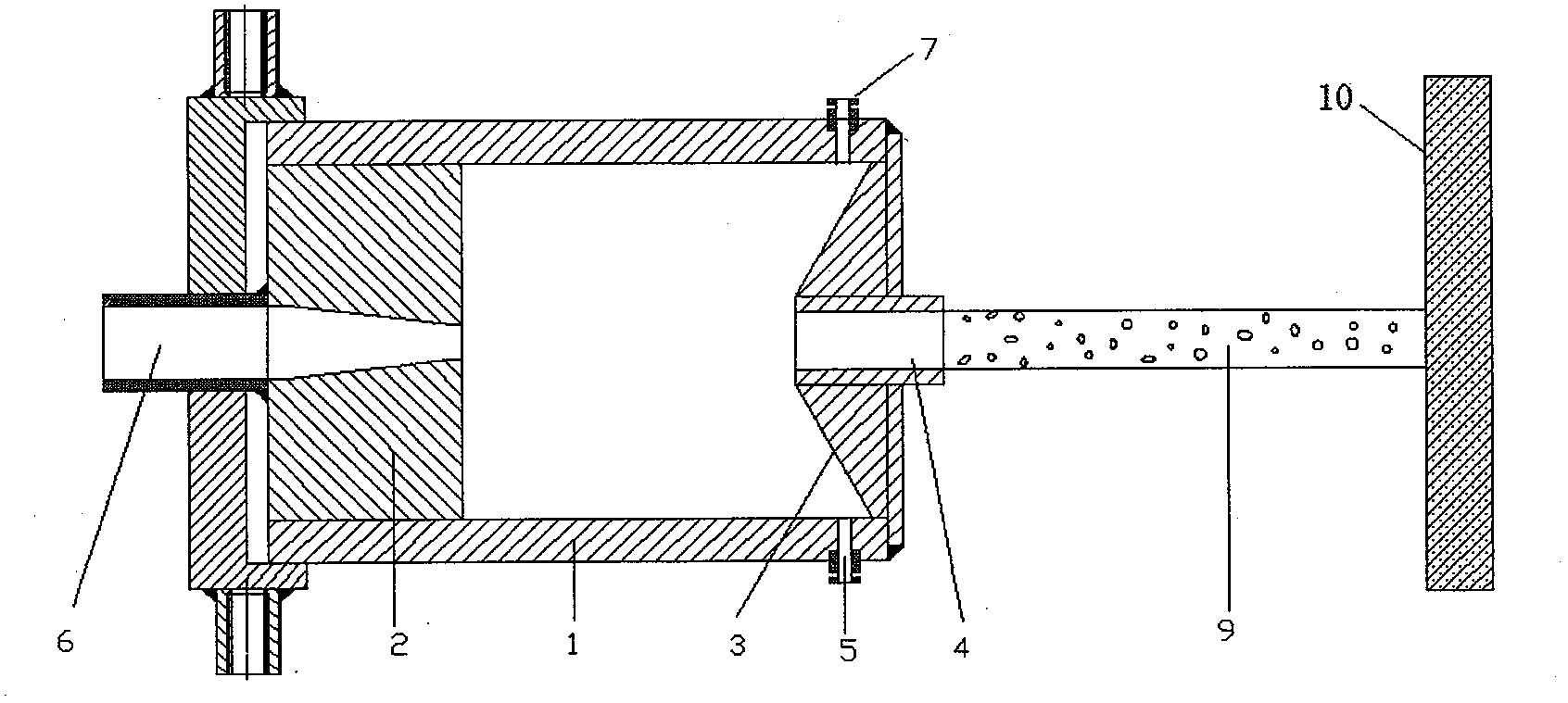

[0023] Such as figure 1 It is a self-excited suction pulse jet nozzle of the present invention, comprising a self-excited oscillation cavity (1), an upper nozzle (2), a collision body (3), a lower nozzle (4), an air suction hole (5), Water inlet section (6) and pneumatic valve (7). exist figure 1 The upper nozzle (2) is fixed at the entrance of the self-excited oscillation chamber (1) shown, and the inlet cross section of the upper nozzle (2) coincides with the entrance cross section of the self-excited oscillation chamber (1). exist figure 1 The outlet end of the self-excited oscillation cavity (1) shown is fixed with a collision body (3), and the lower nozzle (4) is fixed inside the collision body (3), and is symmetrical on the downstream end of the self-excited oscillation cavity (1) The air suction hole (5) is arranged so that a cylindrical self-excited su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com