Expandable quick loading and unloading extrusion head

A technology of extrusion head and expansion type, which is applied in metal extrusion, pressure head/punch rod, metal processing equipment, etc., can solve the problems of excessive aluminum left in the extrusion cylinder and inconvenient cutting, etc., and achieves convenient installation and connection, easy replacement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

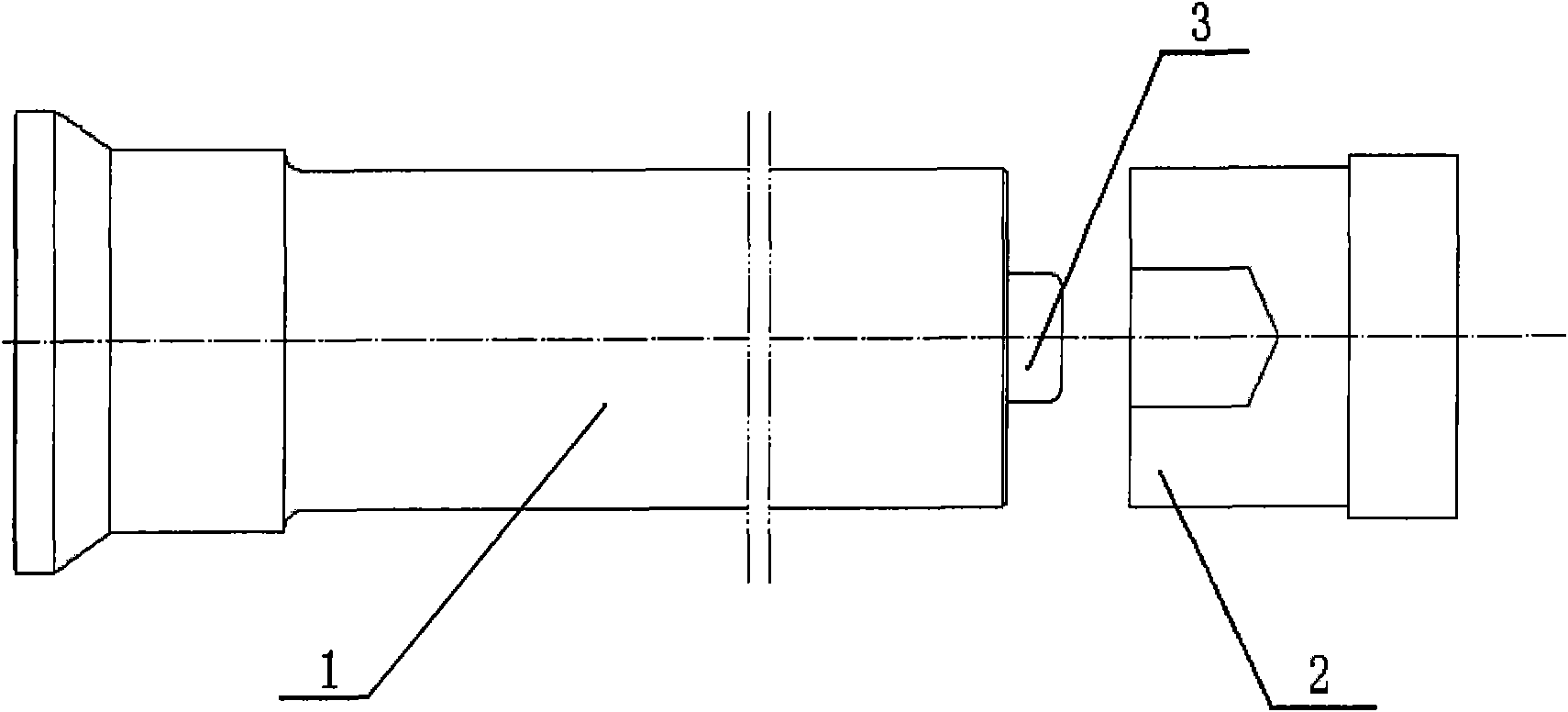

[0013] like figure 1 As shown in the schematic structural diagram of the extrusion head in the prior art, the extrusion rod 1 is provided with a boss 3 , and through the boss 3 , the extrusion rod 1 is directly connected to the extrusion head 2 .

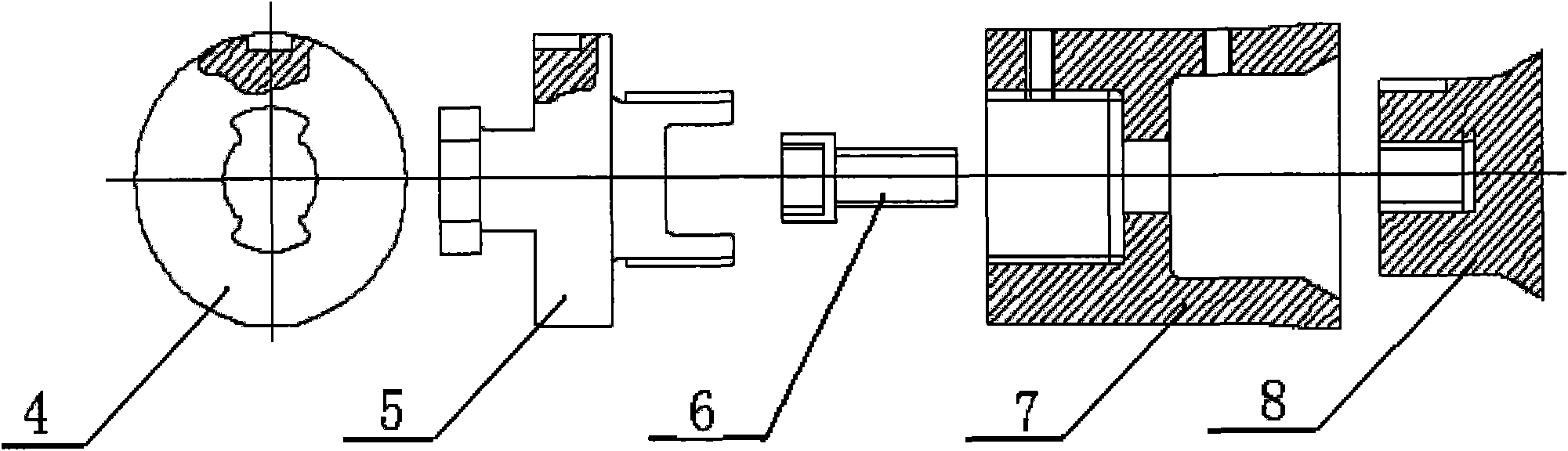

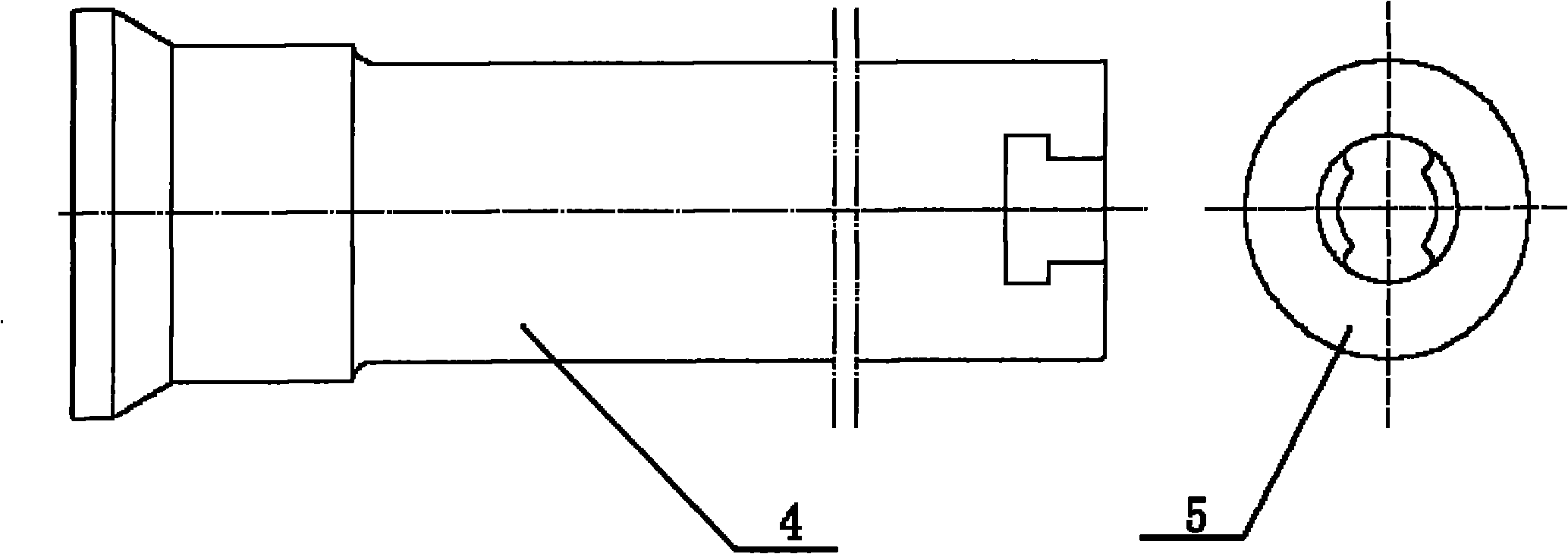

[0014] like figure 2 An expandable quick-loading and dismounting extrusion head of the present invention is shown, the extrusion rod 4 is connected with one end of the connecting body 5; the other end of the connecting body 5 is fixedly connected with the extrusion head cavity 7 through threads; the extrusion head body 8 The screw 6 is fixedly connected with the extrusion head cavity 7; one end of the extrusion head cavity 7 is an open cavity structure, the open cavity outlet of the extrusion head cavity 7 is designed with an oblique angle structure, and the extrusion head body 8 is arranged on the Inside the open cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com