Method for processing defensive move plate structure

A processing method and anti-slip technology, which is applied to metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of uneven structure of the anti-slip surface, easy deformation and misalignment of the anti-slip board, and achieve uniform structure , no misalignment, and the effect of meeting the requirements of surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

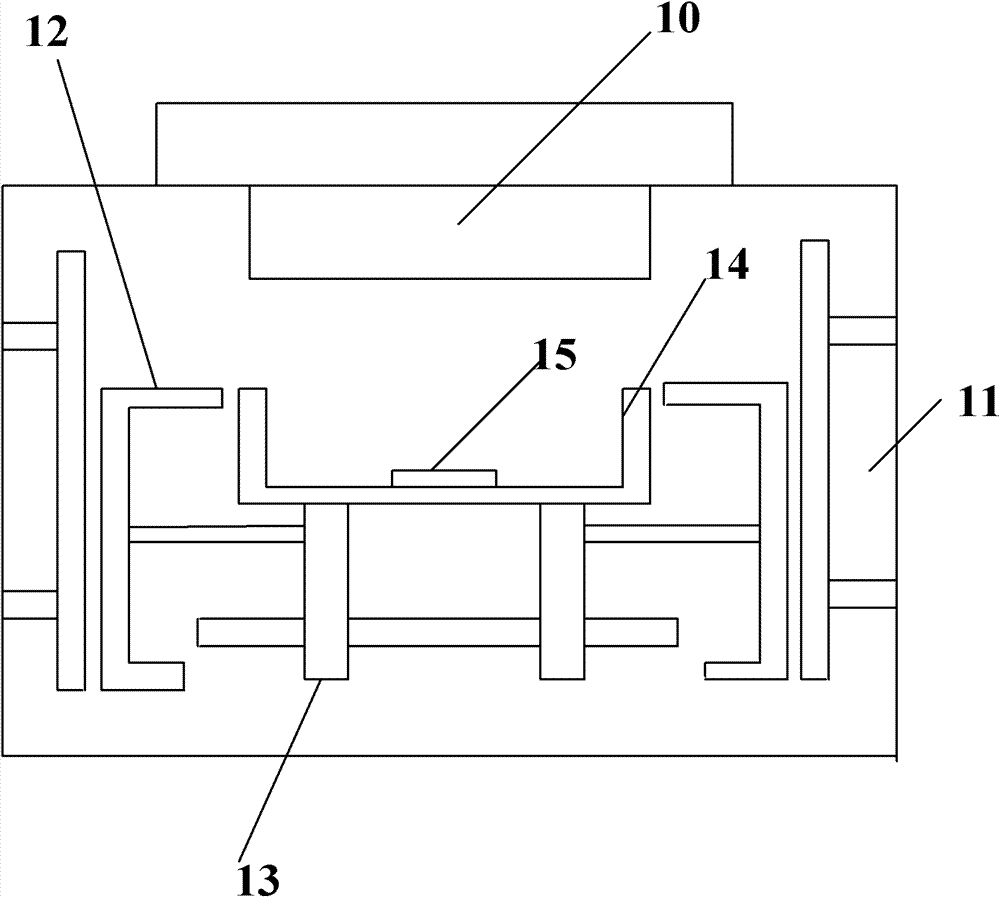

[0025] In the prior art, extrusion molding is used to process the uneven structure of the anti-adhesion surface of the anti-adhesion plate, and the processed anti-anchor plate has an incomplete structure and is easily deformed, and its size cannot meet the requirements of sputtering.

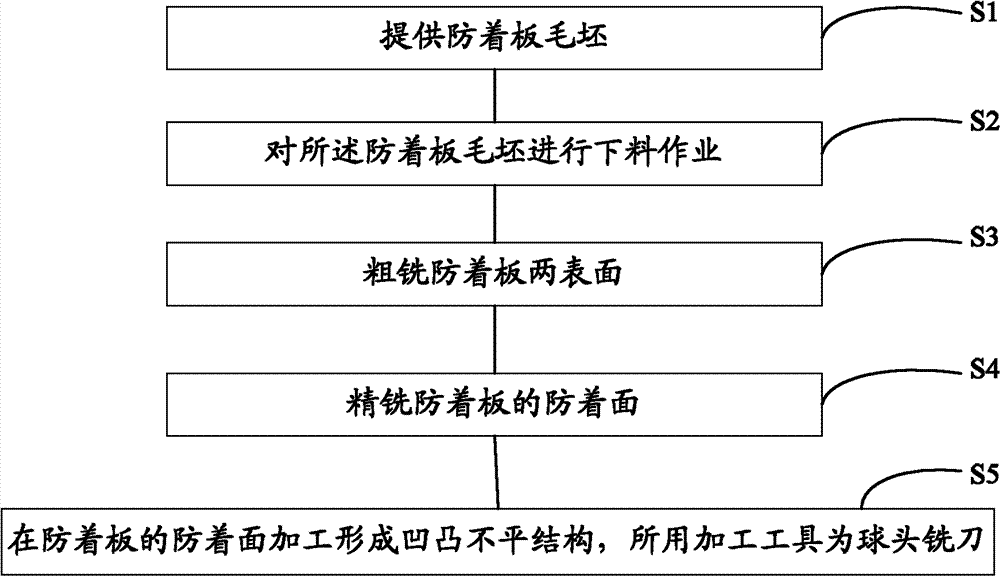

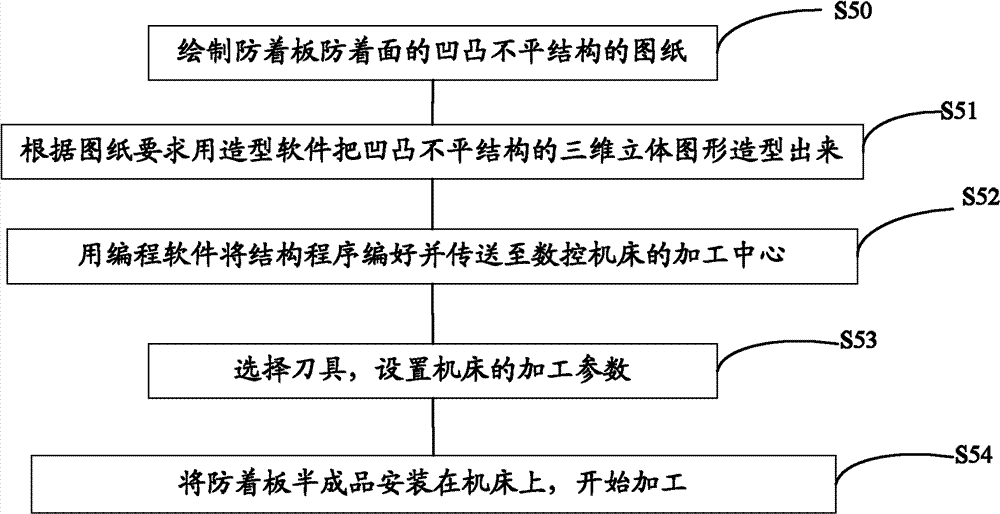

[0026] To this end, the embodiment of the present invention provides a processing method for the uneven structure of the anti-landing plate, including: providing the anti-landing plate blank; performing blanking operations on the anti-landing plate; rough milling the two surfaces of the anti-landing plate; The anti-ground surface of the landing plate; the uneven structure is formed on the anti-ground surface of the anti-landing plate, and the processing tool used is a ball end milling cutter. The diameter of the ball end milling cutter is 2 mm, and the processing parameters are set as the spindle speed of 3500-4500 n / min, the feed speed of 2200-2400 mm / min, and the cutting amount of 0.1-0.2 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com