Automobile tire monitoring device based on organic piezoelectric material

A piezoelectric material, automobile tire technology, applied in tire measurement, tire parts, vehicle parts, etc., can solve problems such as failure to meet actual use, requirements, and patents are rarely applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

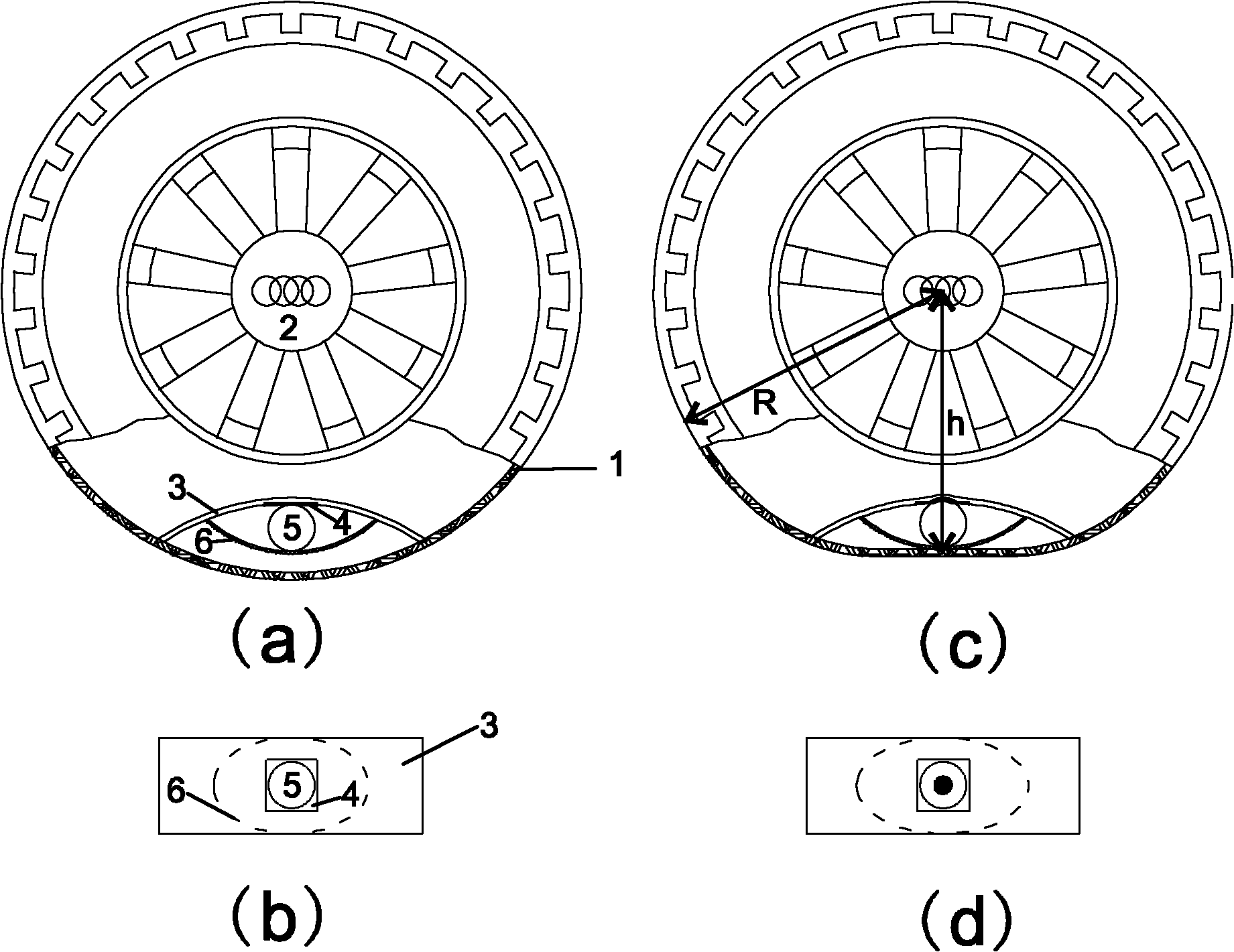

[0052] Embodiment 1: the concrete structure of probe

[0053] The tire 1 used in the experiment is an ordinary car tire with an outer diameter of 60 cm and a tread width of about 20 cm. For the specific probe structure, see figure 1 , The probe base support 3 is a rubber plate with a size of 35cm in length, 18cm in width and 5mm in thickness. The piezoelectric film 4 is a PVDF piezoelectric film with an area of 2cm×2cm, a thickness of 100μm, and a piezoelectric constant d 33 =21pC / N, aluminum electrodes are coated on both sides of the film. The action unit 5 is a table tennis ball with a diameter of 4 cm. The piezoelectric film 4 is attached to the center of the probe base support 3, and the rubber film 6 is a balloon membrane, which fixes the action unit on the probe base support 3, and the action unit 5 is fixed in the middle of the piezoelectric film. When the standard air pressure in the tire, the bottom of the rubber film 6 is 1 cm away from the inner surface of the...

Embodiment 2

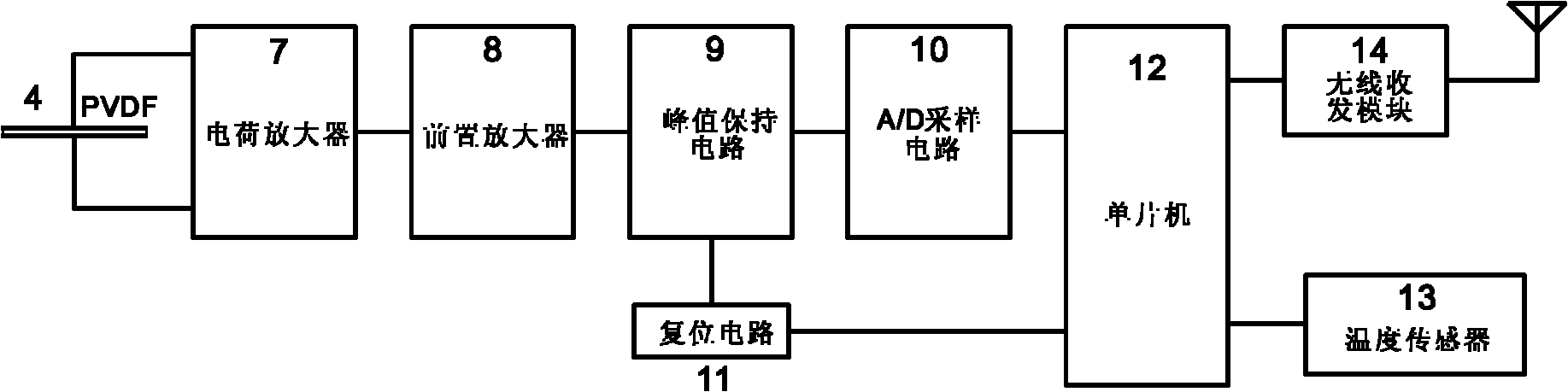

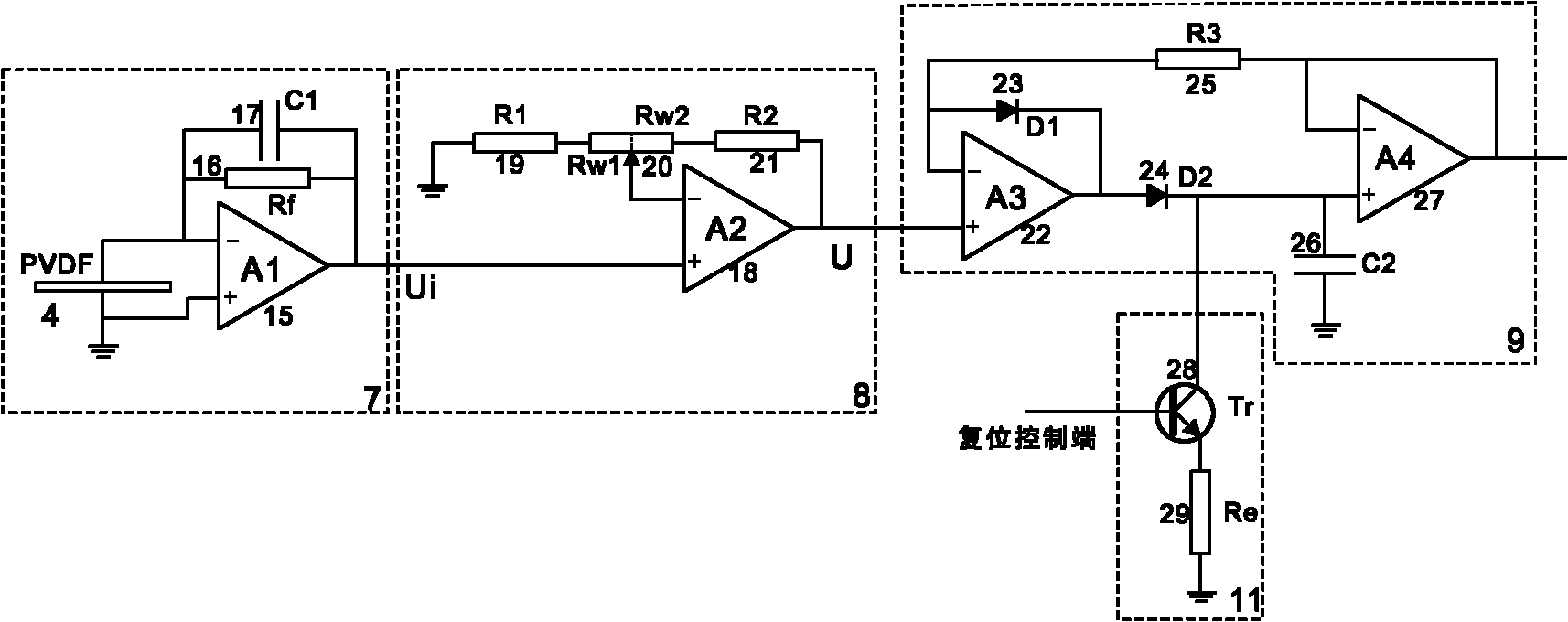

[0054] Embodiment 2: Piezoelectric signal conversion and processing circuit

[0055] Such as image 3 As shown, the integrating capacitance 17 of the charge amplifier 7 is 4700pF, and the resistance value of the feedback resistor 16 is 3.3MΩ. The resistors 19, 21 and the adjustable resistor 20 in the preamplifier 8 are 12kΩ, 110kΩ and 200kΩ respectively. In the peak holding circuit 9, the resistor 25 is 10kΩ, the voltage holding capacitor 26 is 0.1μF, and the rectifier diodes 23 and 24 are 1N4148. The transistor 28 of the reset circuit 11 is 2SC1815, and the emitter resistor 29 is 1kΩ. image 3 The operational amplifiers 15, 18, 22, and 27 used in each signal processing circuit in the circuit have selected a general-purpose low-noise high-precision operational amplifier OP-07. Such as figure 2 The shown temperature sensor 13 uses a platinum thermistor, the single-chip microcomputer 12 uses AT89C52, and the wireless transceiver module 14 selects 24L01, and the single-chip ...

Embodiment 3

[0057] Example 3: Design of a single-supply charge amplifier

[0058] The experimental design of a single-supply charge amplifier such as Figure 5 As shown, the single-supply operational amplifier 33 is LM358, the resistor 31 is 130kΩ, the integral capacitor 32 is 1000pF, the Zener diode 30 is 1N4746A, the filter resistor 34 and filter capacitor 35 are 130kΩ and 0.1μF respectively. The supply voltage for the circuit is 15V and ground (0V).

[0059] Similarly, at an ambient temperature of 15°C, when the excitation frequency f is about 1.67 Hz, the voltage output of the single-supply charge amplifier changes with the action distance x of the action unit 5 as follows: Figure 8 As shown, (a), (b), (c) and (d) in the figure correspond to the situations when x=0, 3mm, 9mm and 15mm respectively. Figure 9 The relationship curve of the peak value of the charge amplifier U with the operating distance x is based on Figure 8 The waveform voltage signal U waveform is obtained from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com