Temperature sensitive ink

A temperature-changing ink and temperature-changing technology, applied in inks, household appliances, applications, etc., can solve the problem of temperature-changing inks that cannot withstand high temperature and high pressure water vapor, and achieve excellent temperature change effect, good use effect, and increase value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

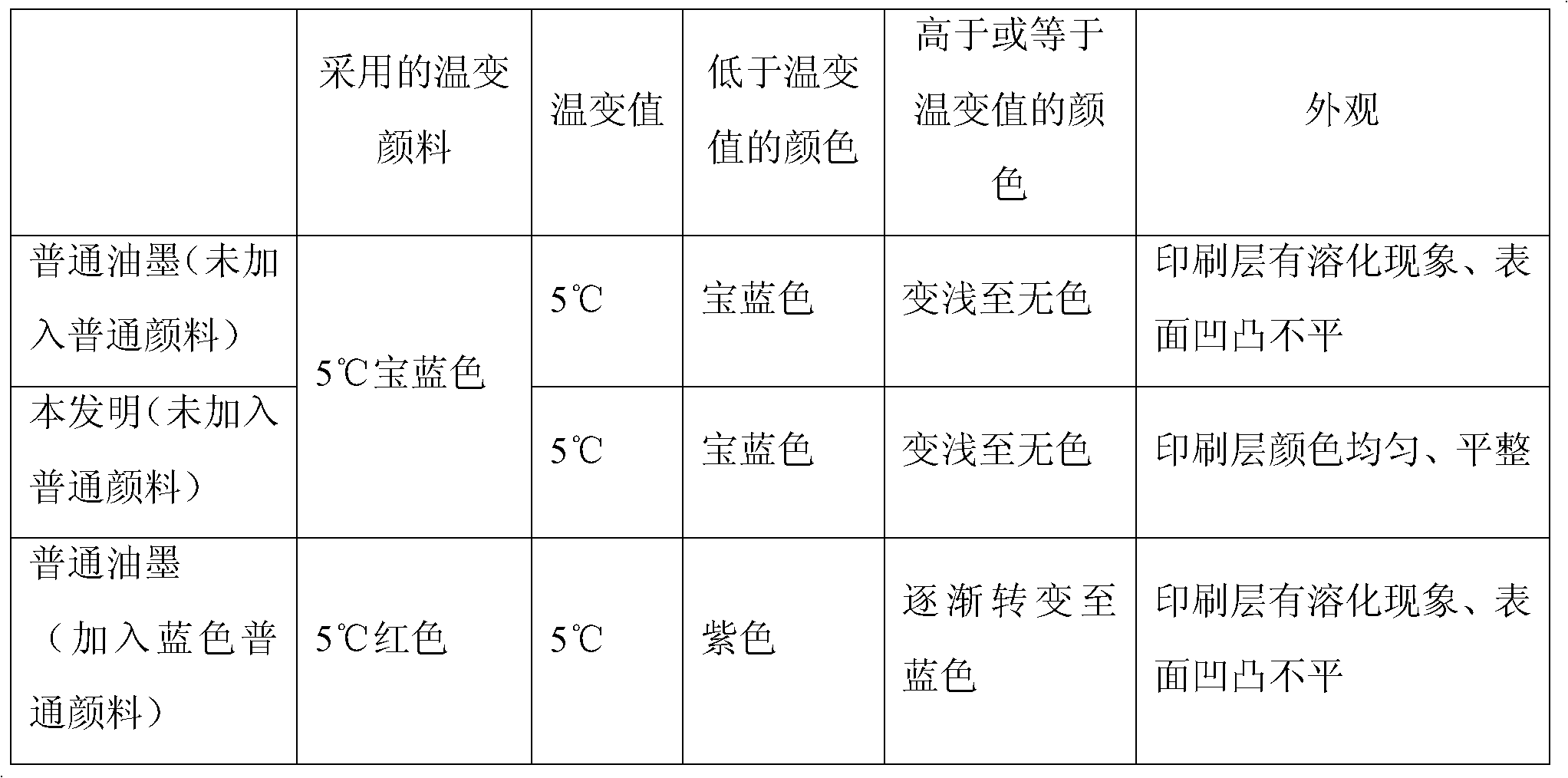

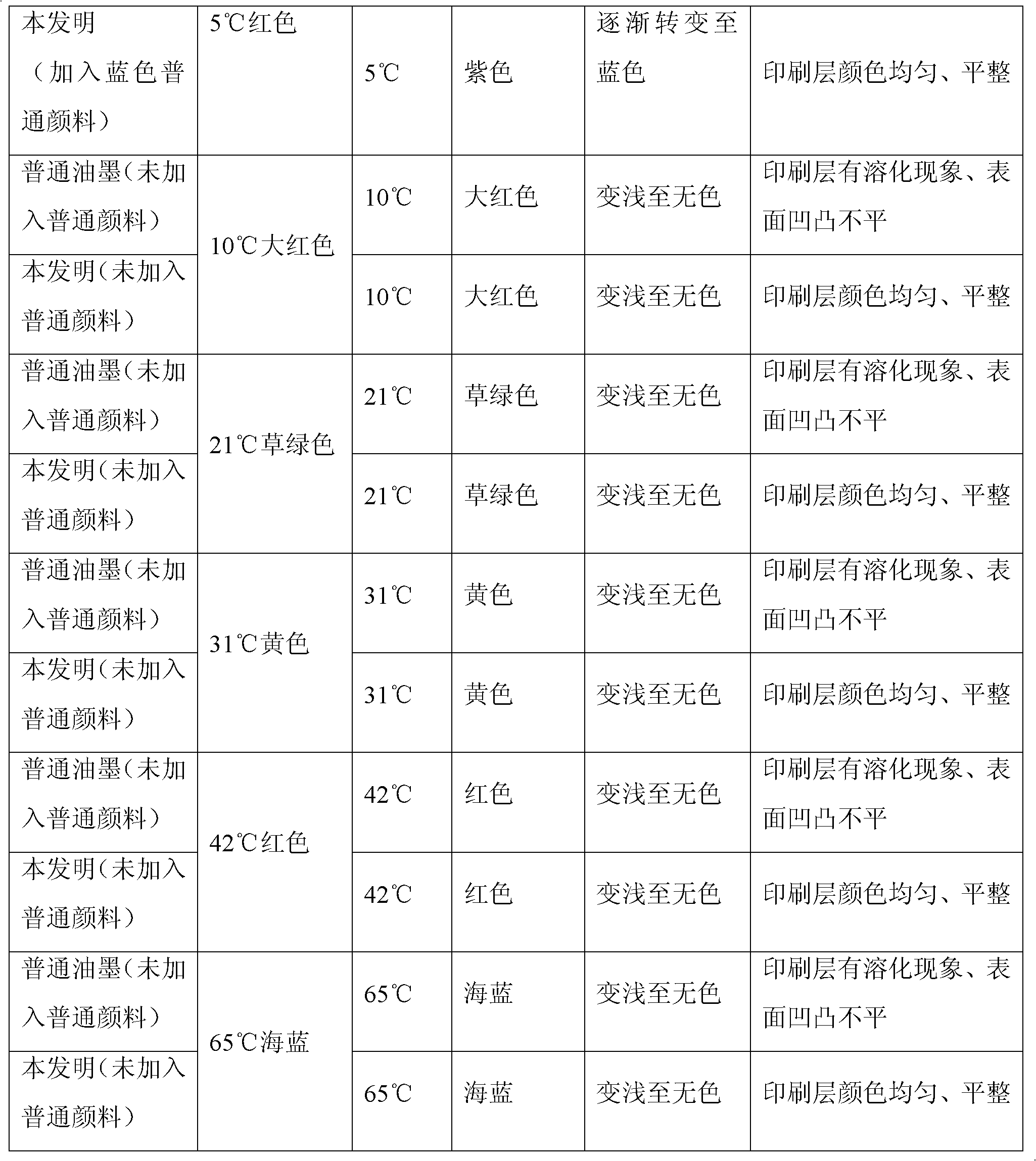

[0029] Embodiment 1: A temperature-changing ink is mainly made of the following raw materials in parts by weight:

[0030] Polyamide resin 57, temperature-varying pigment 25, m-xylylenediamine 16, palm oil 2. Among them, the temperature-changing pigment is a 10°C red organic heat-sensitive temperature-changing pigment (red below the temperature change value).

[0031] The temperature-changing ink of this embodiment is prepared in 1 kg, mixed according to the above formula ratio and fully ground with a grinder, to obtain an ink with temperature change and resistance to traditional sterilization processes. The temperature change value of the prepared temperature-changing ink is 10°C, and it turns red below 10°C, and the red color gradually becomes lighter until it is colorless above 10°C.

Embodiment 2

[0032] Embodiment 2: A temperature-changing ink is mainly made of the following raw materials in parts by weight:

[0033] Epoxy resin 57, temperature-changing pigment 15, ordinary pigment 10, m-xylylenediamine 16, palm oil 2. Among them, the temperature-changing pigment is 10°C red organic heat-sensitive temperature-changing pigment (red below the temperature change value); the ordinary pigment is phthalocyanine blue (blue).

[0034] The temperature-changing ink of this embodiment is prepared in 1 kg, mixed according to the above formula ratio and fully ground with a grinder, to obtain an ink with temperature change and resistance to traditional sterilization processes. The temperature change value of the prepared temperature-changing ink is 10°C, and it is purple below 10°C, that is, the mixed color of the red of the temperature-changing pigment and the blue of the ordinary pigment, and the purple gradually turns into blue above 10°C. The red ink becomes colorless, and the ...

Embodiment 3

[0035] Embodiment 3: A temperature-changing ink is mainly made of the following raw materials in parts by weight:

[0036] Epoxy resin 54, temperature-varying pigment 23, mixture 20 of m-phenylenediamine and diaminodiphenylmethane, corn oil 3. Among them, the temperature-changing pigment is a 16°C red organic heat-sensitive temperature-changing pigment (red below the temperature change value). Wherein the volume ratio of the two components in the mixture of m-phenylenediamine and diaminodiphenylmethane is 60:40.

[0037] The preparation method is the same as in Example 1, and will not be described in detail here. The temperature change value of the prepared temperature change ink is 16°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com