Steep slope protective soft frame and construction method thereof

A construction method and characteristic technology, applied in the fields of botanical equipment and methods, excavation, infrastructure engineering, etc., can solve the problems of short service life, crushed flexible protective belt, low strength, etc., so as to improve the service life and reduce maintenance costs. , the effect of optimizing the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

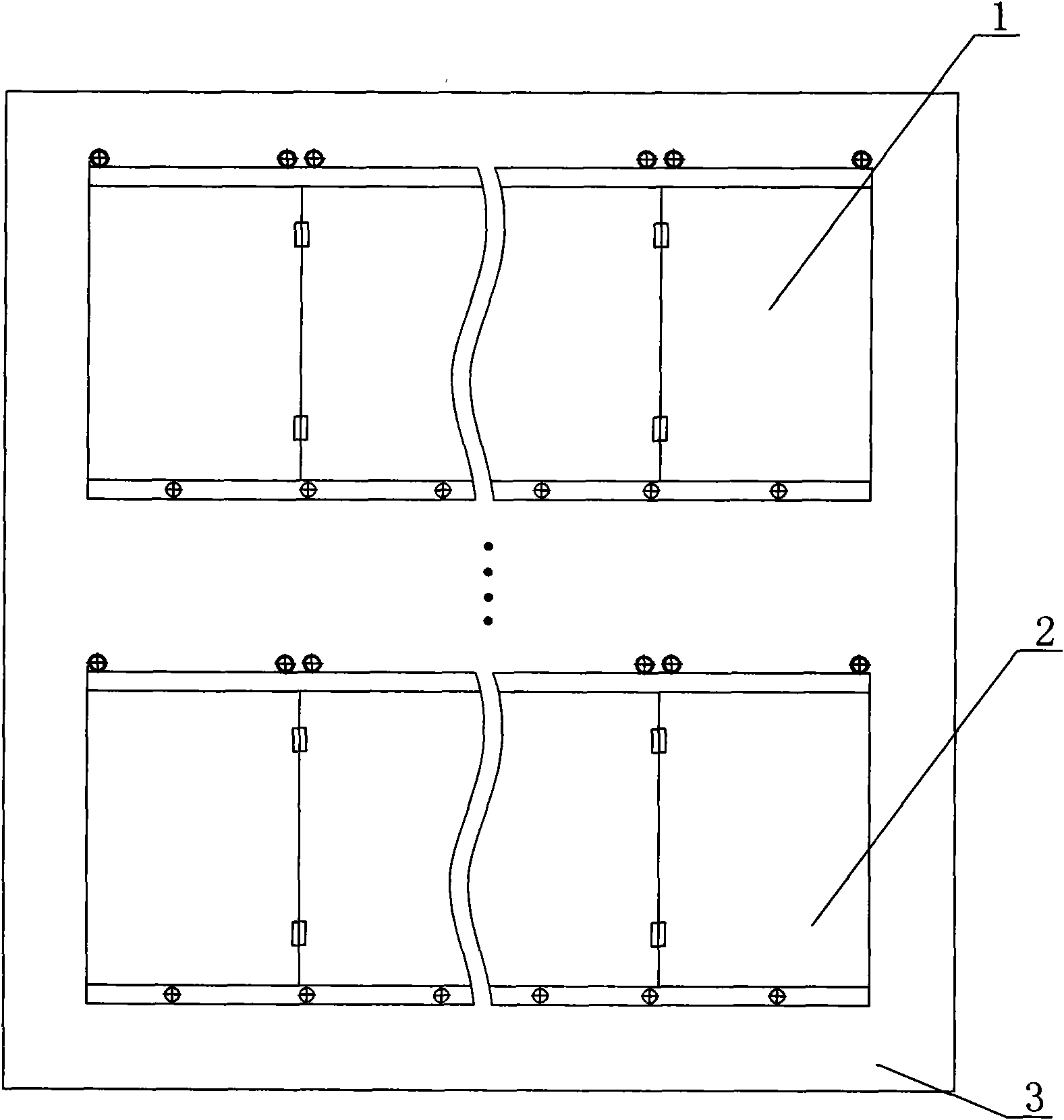

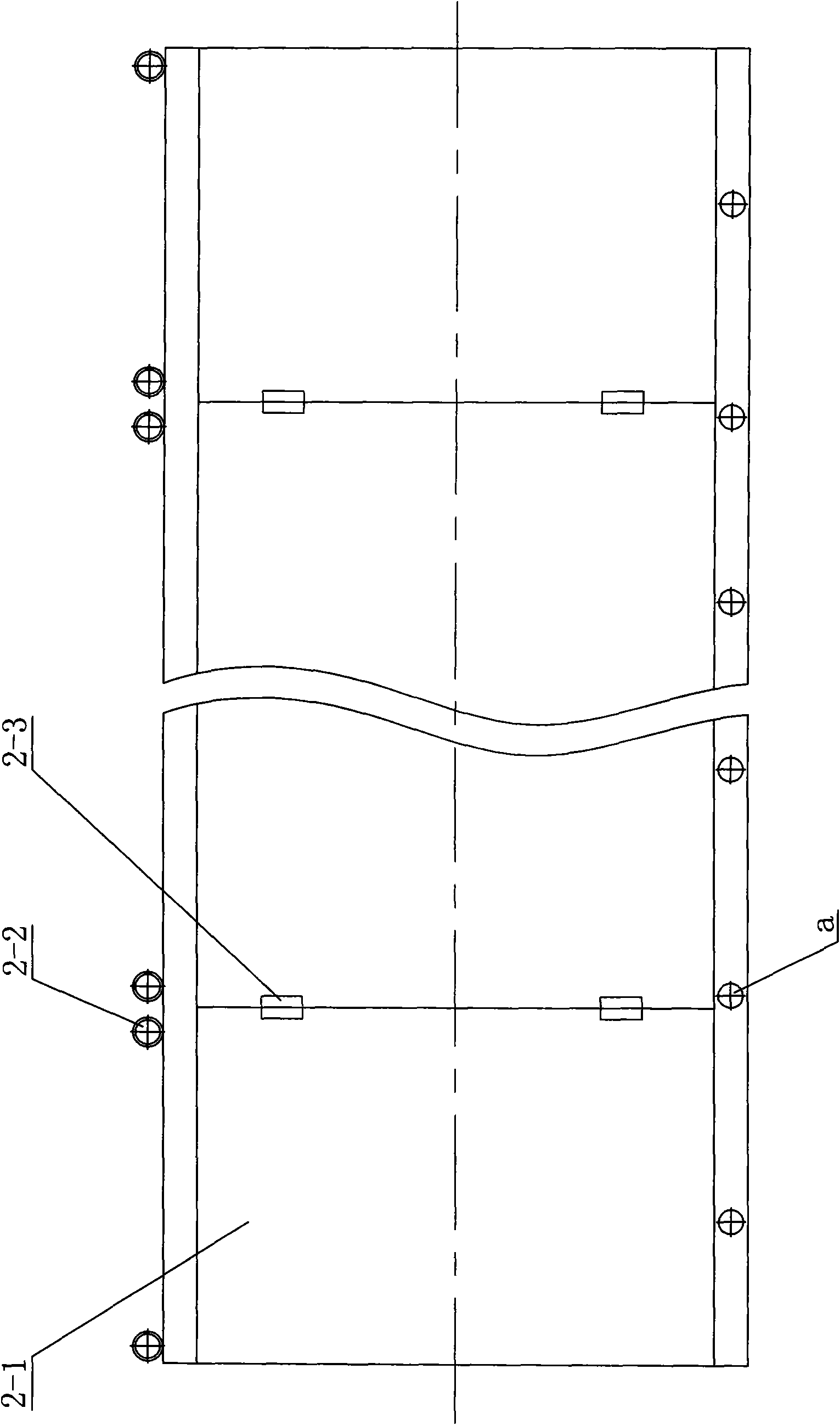

[0026] exist Figure 1~5 Among them, the flexible grid frame for steep slope protection in this embodiment consists of the first layer of flexible grid frame 2 fixed on the steep slope 3, the second layer of flexible grid frame fixed above the first layer of flexible grid frame 2 on the steep slope 3 until the slope The top floor flexible grid frame 1 of the top platform is fixed on the slope top platform to form a stepped structure.

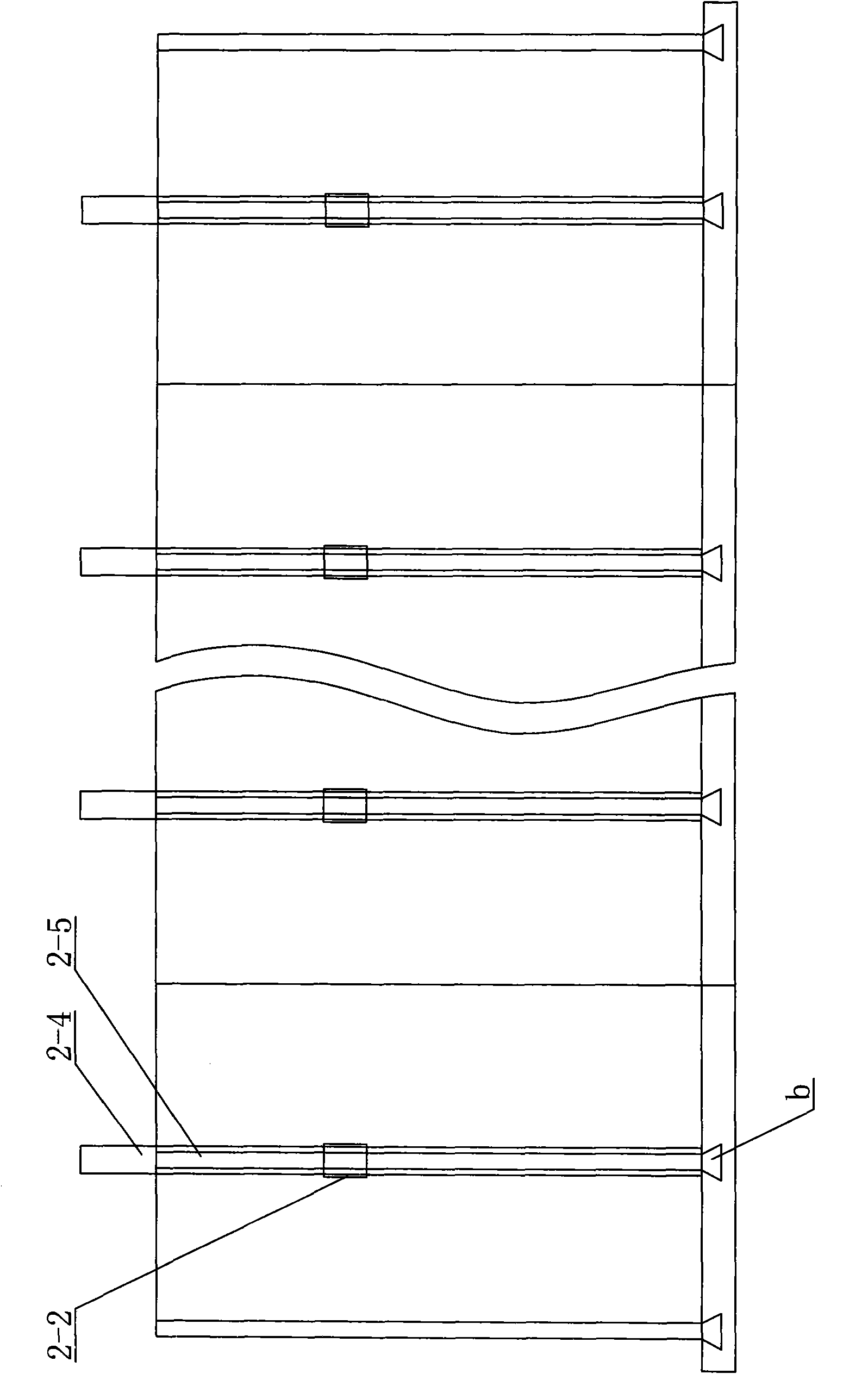

[0027] The flexible grid frame 2 of the first layer is made of the same flexible grid frame connected to each other. The flexible grid frame is composed of a panel 2-1, a shaft sleeve 2-2, a connecting ear 2-3, an anchor rod 2-4, and a dividing plate 2-5. The panel 2-1 of this embodiment is made of polyvinyl chloride by one-time molding, and the four sides of the back side of the panel 2-1 are casted with a frame, which plays a strengthening role and improves the service life of the present invention. The bottom of the panel 2-1 is once A conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com