Nuclear power station steel lining modularized construction method

A construction method and technology of steel lining, applied in industrial buildings, buildings, building structures, etc., can solve the problems of long aerial work, small operation space, high safety risks, etc., to improve construction economy, improve the degree of molding, The effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the drawings. The nuclear power plant steel lining modular construction of this embodiment is carried out according to the following steps:

[0027] 1. Prefabricated lining module - steel lining in the shape of a tank as a whole (see Figure 7 ) is divided into multi-level ring-shaped lining modules with a height of 5.75m. After prefabrication in the workshop, the assembly site is selected to make it into lining modules of all levels.

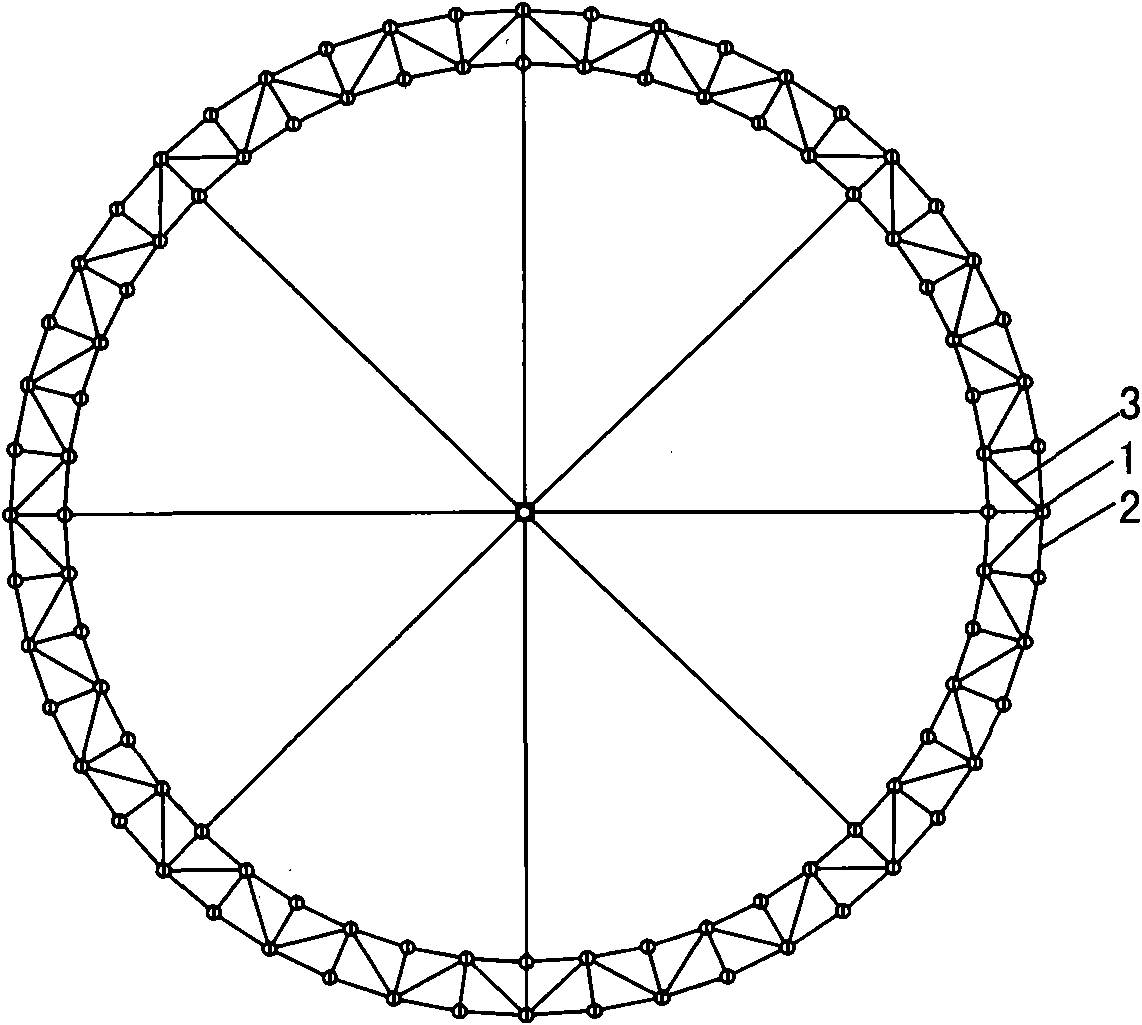

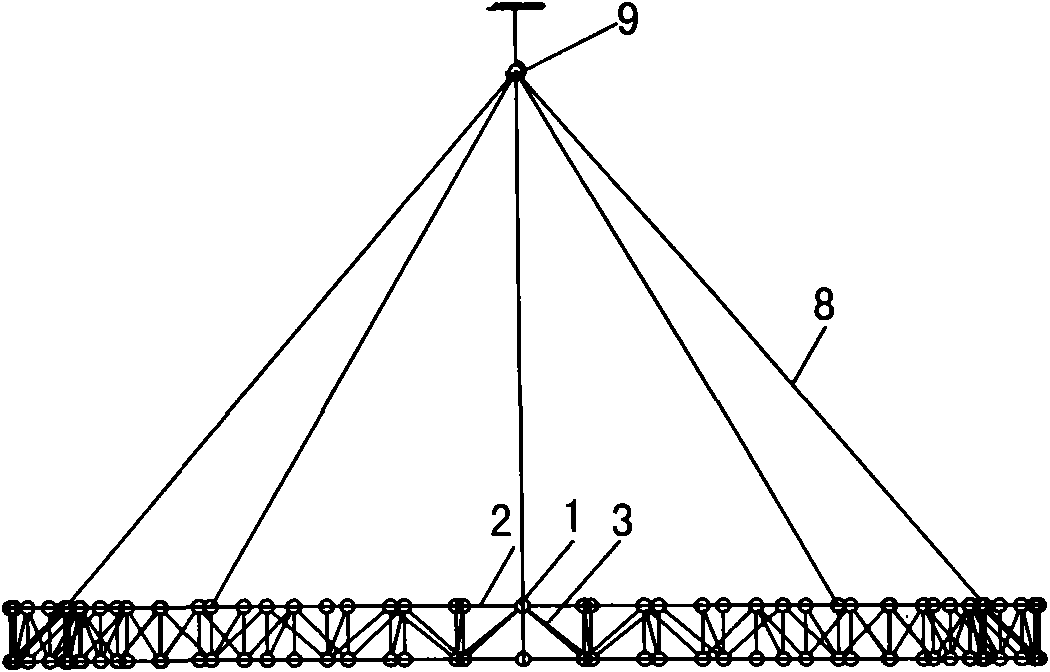

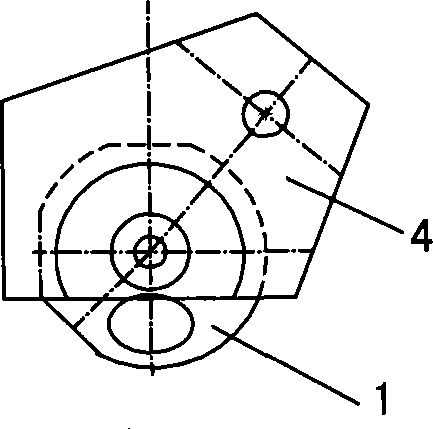

[0028] 2. Manufacture hoisting grid—such as figure 1 and figure 2 As shown, the node spheres 1 with connecting screw holes are distributed according to the inner and outer circles and the upper and lower layers, and the two node spheres that are adjacent to the left and right, adjacent to the upper and lower, and adjacent to the inner and outer sides are respectively passed through the terminal with external threads. Horizontal, vertical and longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com