Preparation method of photovoltaic triangular welding strip

A delta welding and photovoltaic technology, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of the reduction of wire tensile capacity and elongation at break, the reduction of the effective reflection area of the welding strip, and the reduction of the mechanical properties of the wire, etc. problem, to achieve the effect of increasing light utilization rate, improving effective reflection area, and increasing effective reflection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] The invention provides a preparation method of triangular soldering ribbon for photovoltaics, which includes metal wire shaping and metal wire tinning; the metal wire can be copper wire; the metal wire can be shaped first, and then the metal wire can be tinned; Tinning the wire, and then shaping the wire;

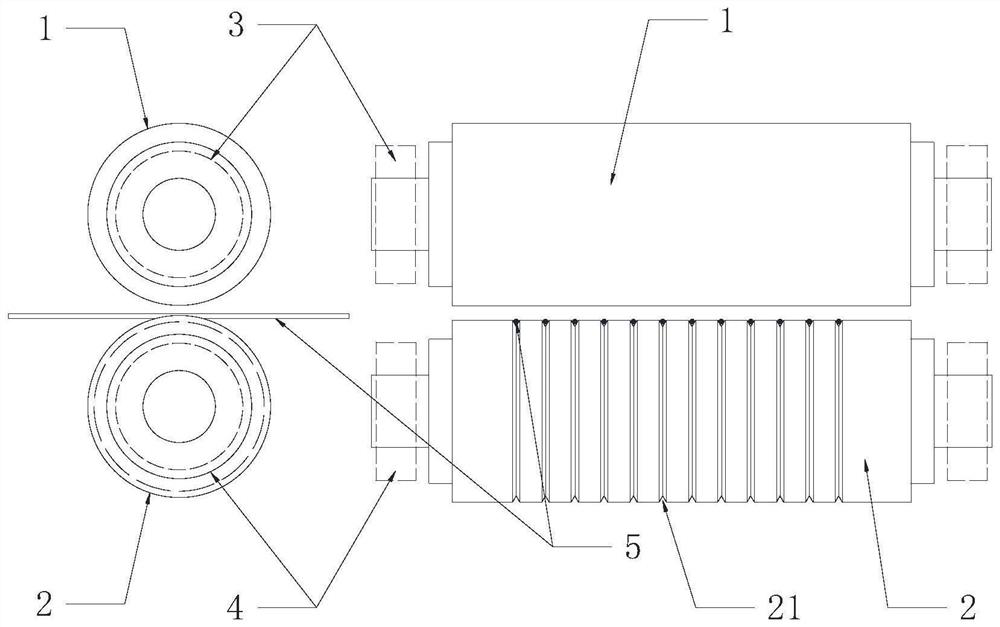

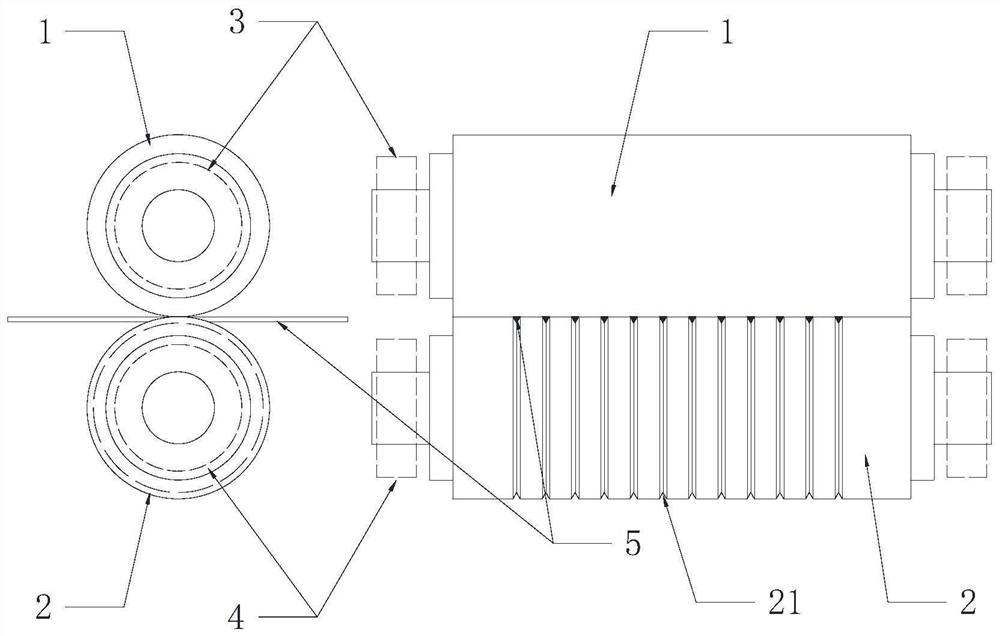

[0030] Such as figure 1 with figure 2 As shown, the metal wire shaping includes: using a pair of rollers 1, 2 to roll the circular cross-section metal wire 5, and the metal wire 5 cross-section is shaped into a triangle;

[0031] The pair of rollers includes: a first roller 1 used as a bottom surface molding support for the triangular section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com