LED tube lamp

A technology of LED downlights and electrodes, applied in cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve problems such as cumbersome process, complex structure of downlights, damaged parts, etc., to achieve Improve process efficiency, simplify product structure and assembly process, and facilitate disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

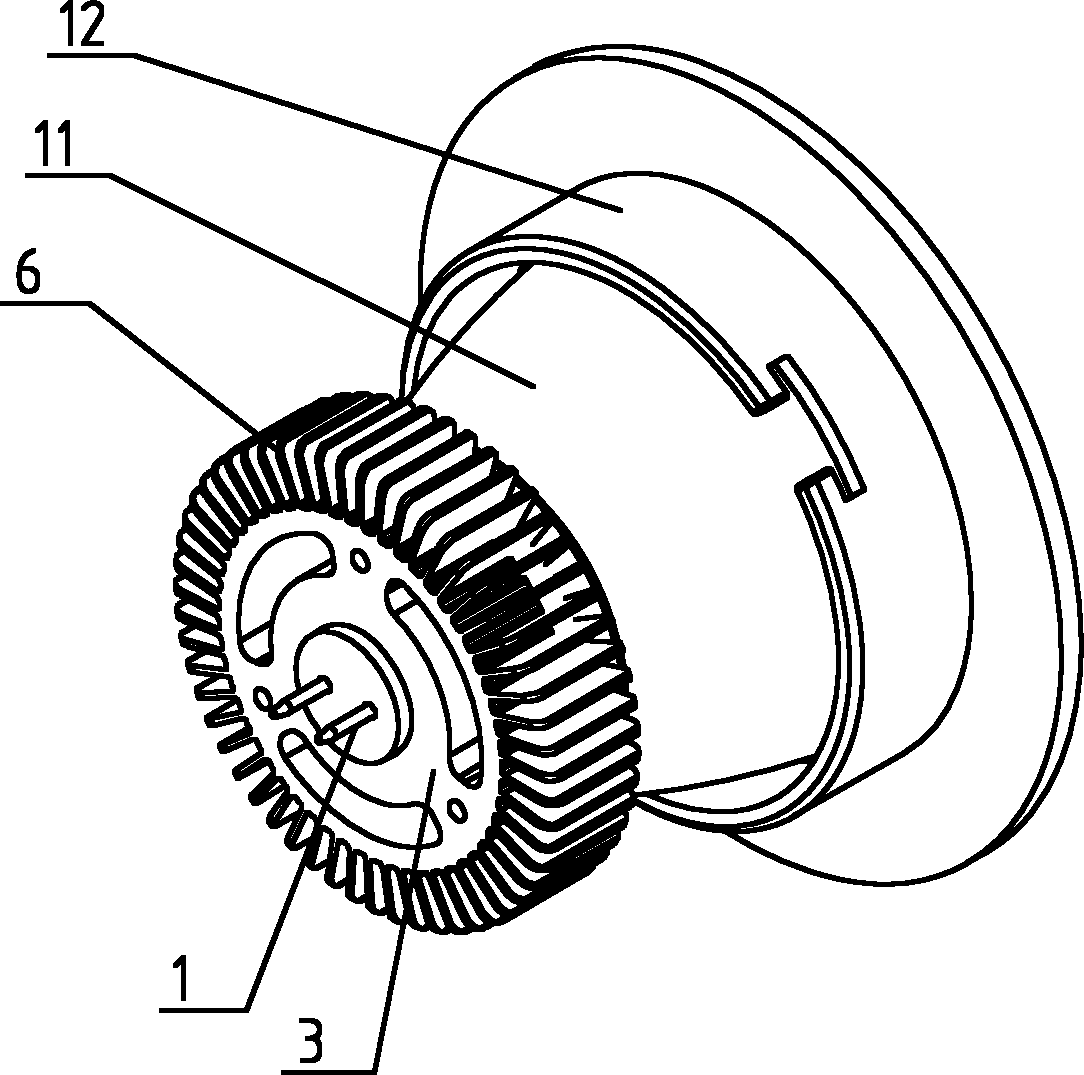

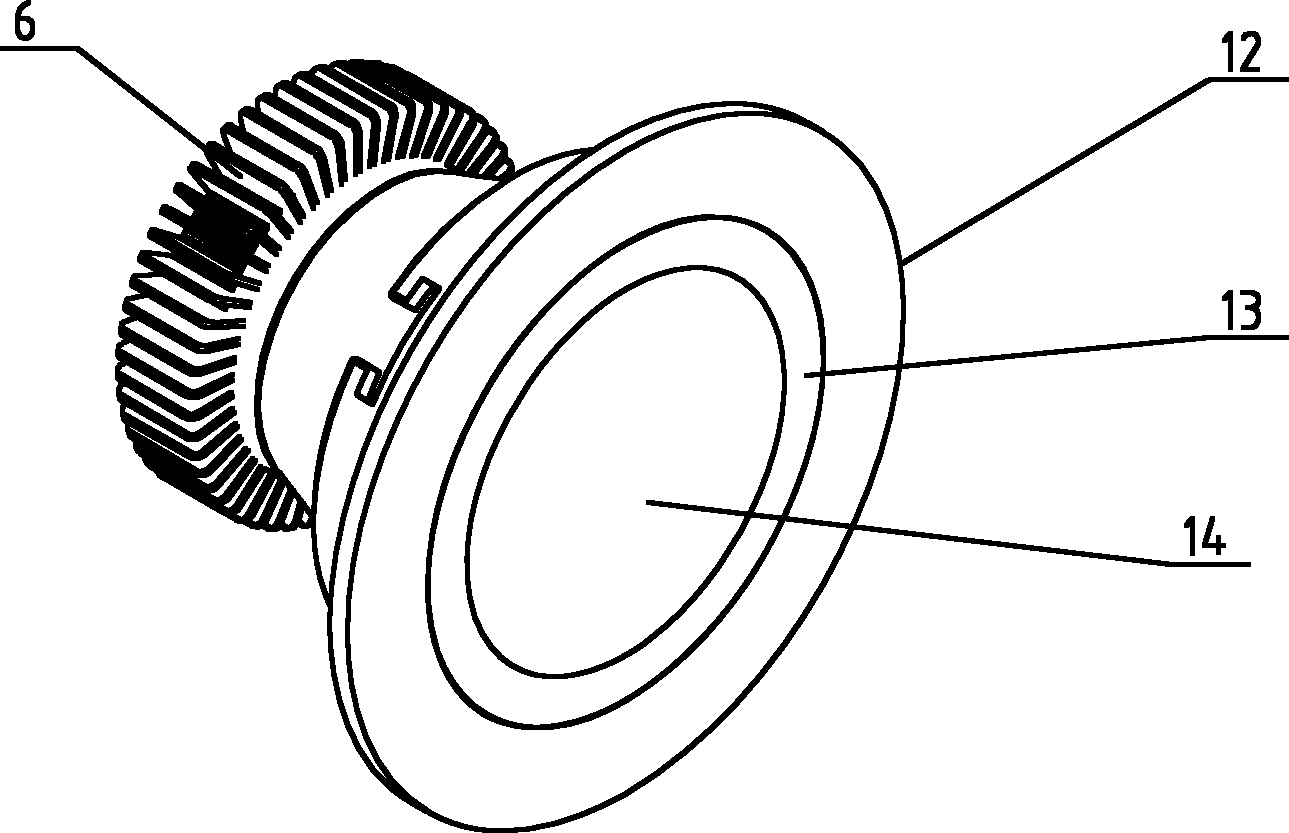

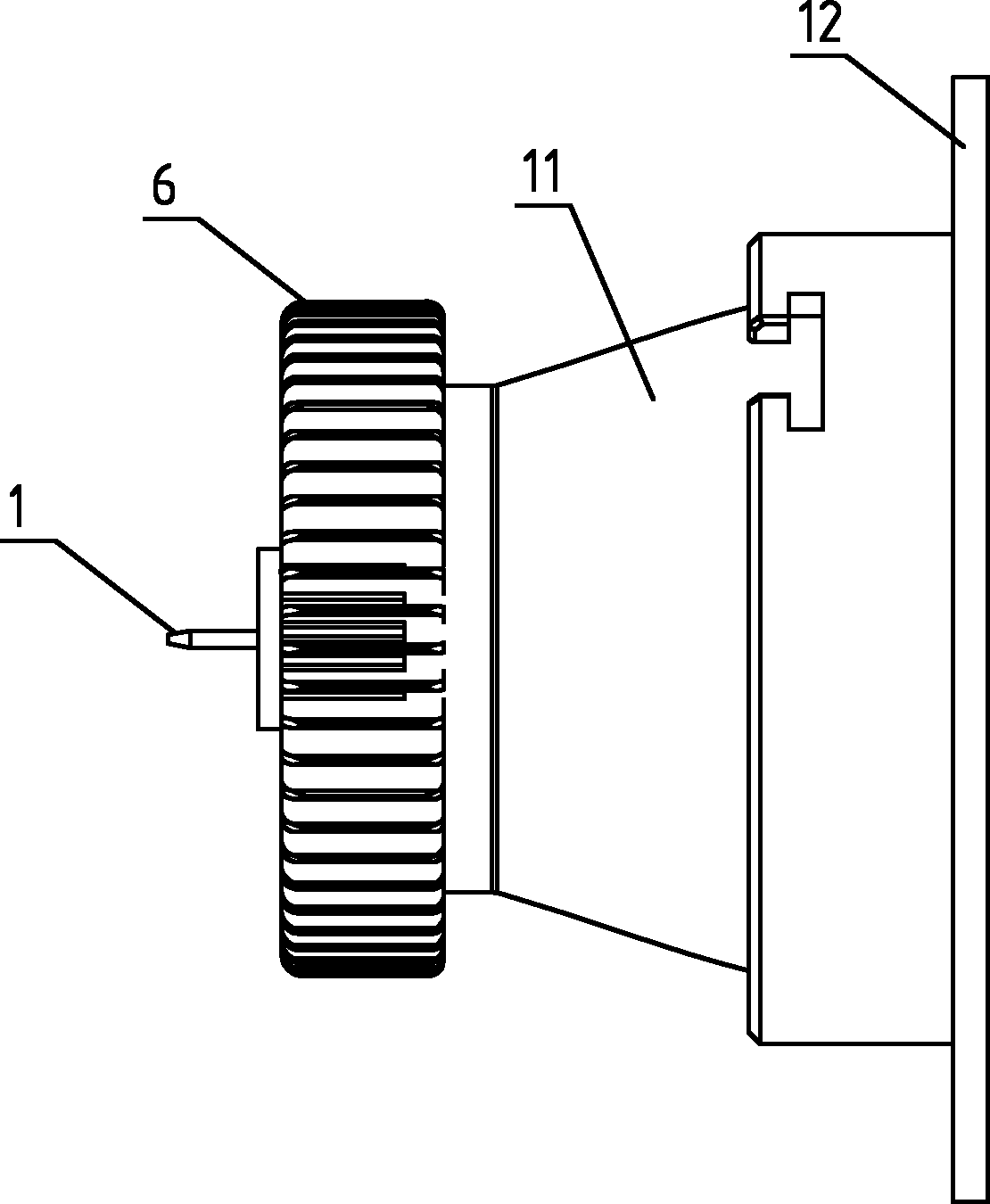

[0025] Such as Figures 1 to 6 As shown, the LED downlight of this embodiment includes a substrate 10, a heat sink 6, a power supply conductive terminal 1, an electrode seat 3, and an LED conductive terminal 2. The power supply conductive terminal 1 is connected to an external power supply or a power supply drive module inside the LED downlight connection, the electrode seat 3 is used to support the conductive terminals of the power supply, and the heat sink 6 is fixed on the periphery of the substrate 10 to realize heat dissipation.

[0026] The side of the substrate 10 used for emitting light encapsulates at least one LED lamp bead 9 , and the substrate 10 is detachably connected to the power supply conductive terminal 1 through the LED conductive terminal 2 and conducted. Specifically, there are two LED conductive terminals 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com