Solar transparent heat insulation pipe

A thermal insulation tube and solar energy technology, which is applied in the field of solar energy application, can solve the problems of small size, peeling and peeling, etc., and achieve the effects of reducing costs, improving efficiency, and improving overall thermal insulation performance and heat collection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

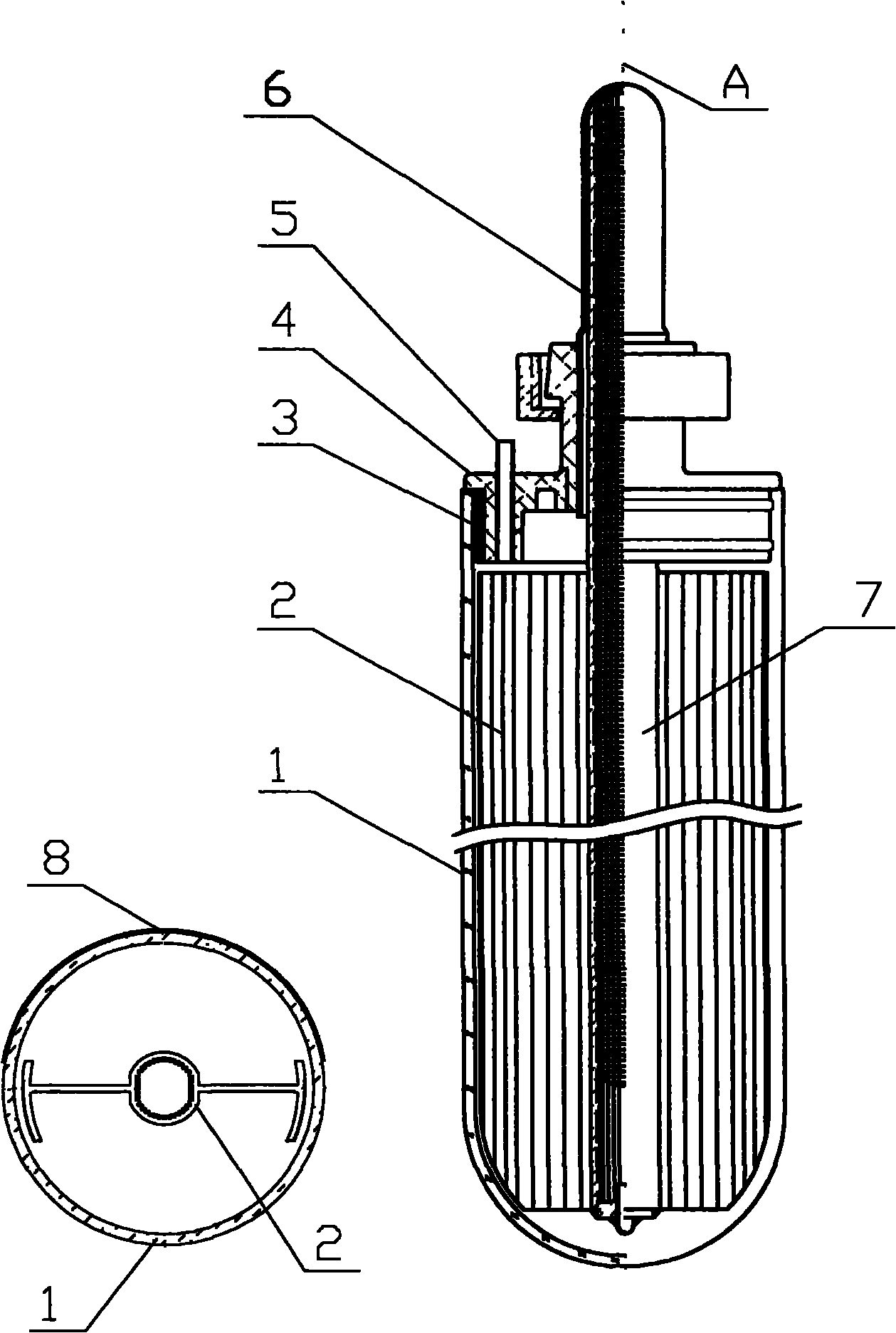

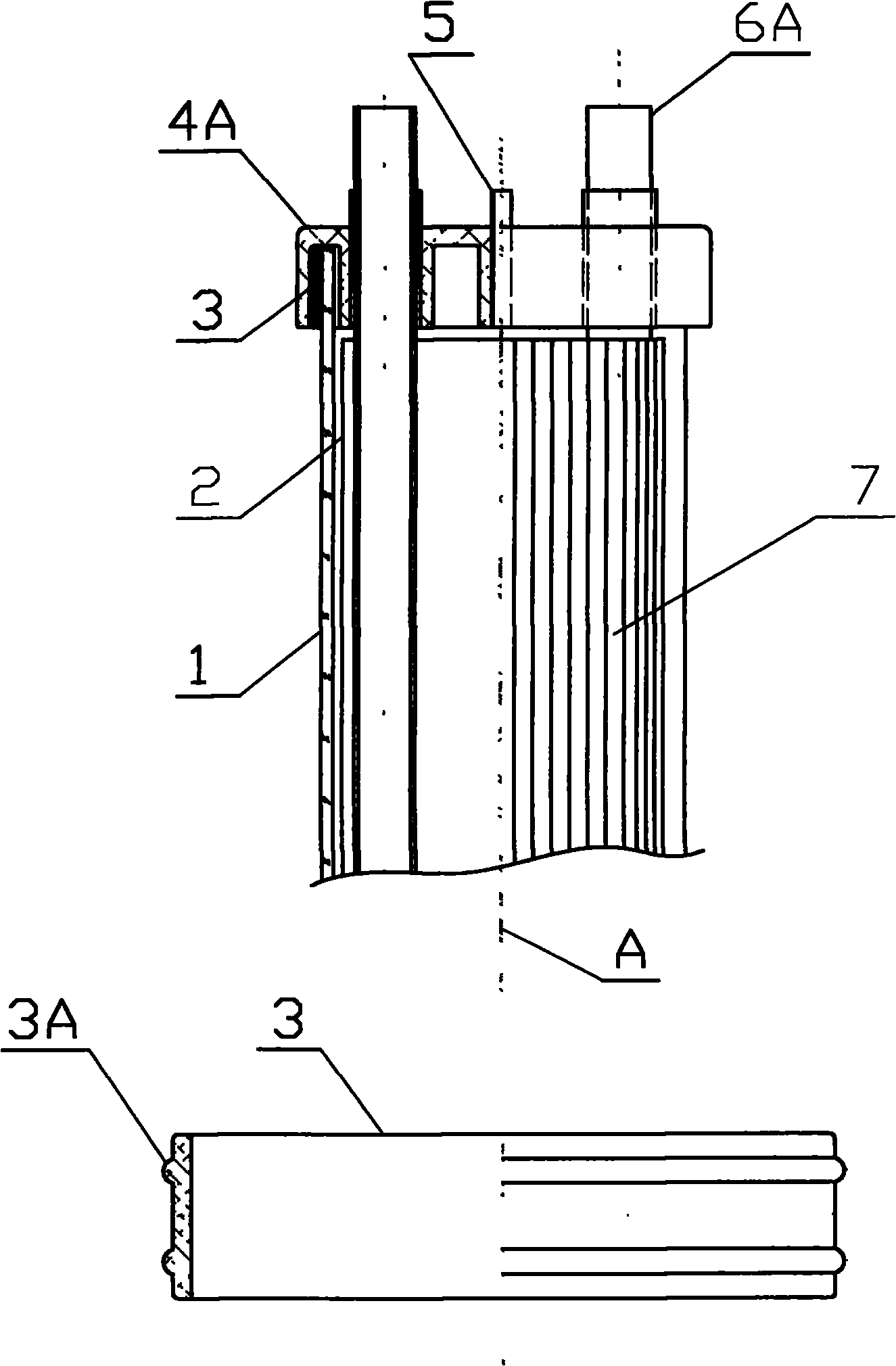

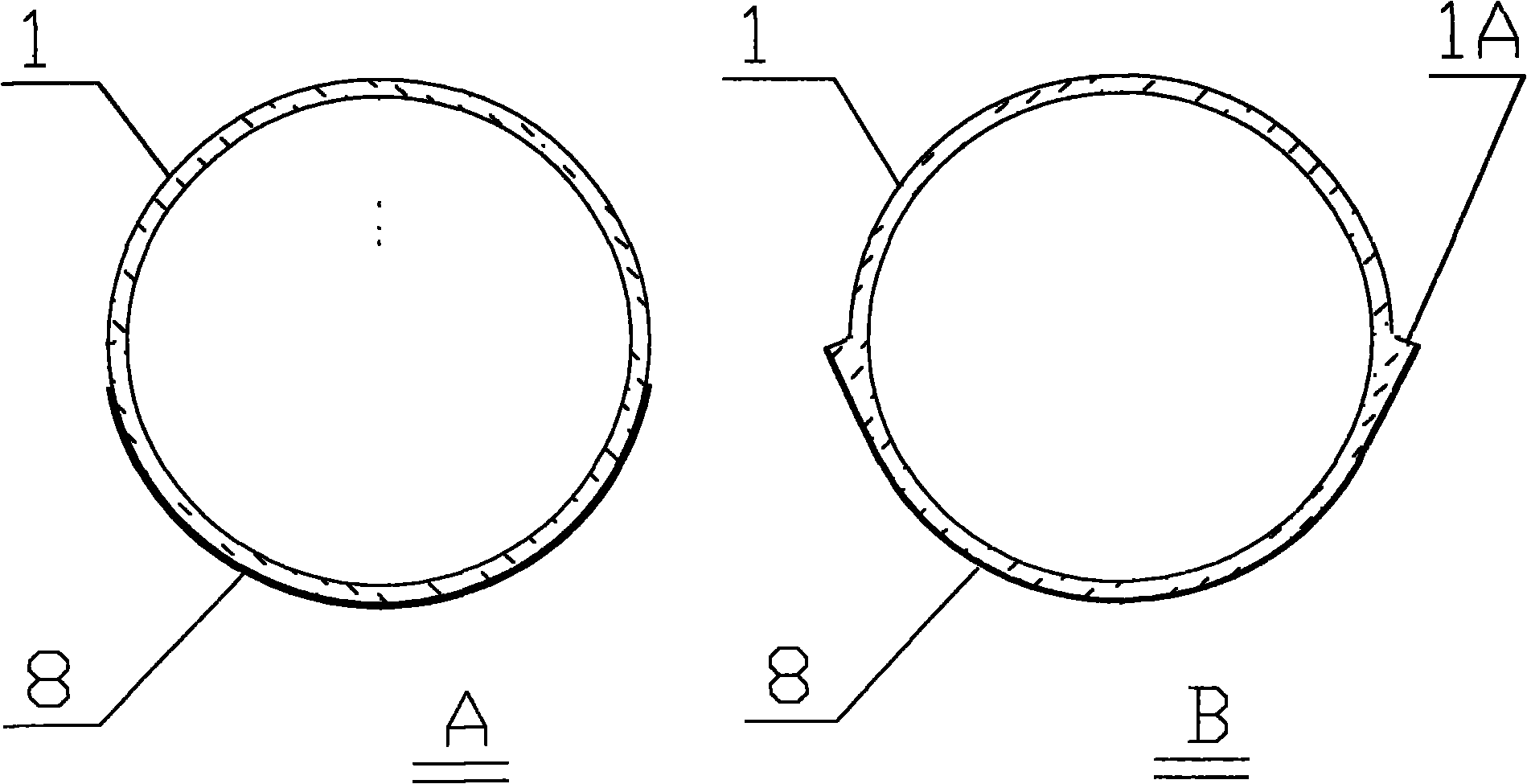

[0028] The accompanying drawing is an example of a solar energy "transparent thermal insulation pipe", which discloses non-restrictive specific embodiments of the present invention, and is equally applicable to other types of solar heat collecting pipes of tubular structure. The present invention is further described as follows in conjunction with the accompanying drawings.

[0029] See attached figure 1 and 2 , solar energy " transparent insulation pipe " of the present invention, its structure mainly comprises transparent insulation pipe 1, sail type fin 2, rubber sealing ring 3, sealing cover 4 (or 4A), exhaust pipe 5, heat pipe 6 (or 6A) and reflective film 8, the exhaust pipe 5 is inlaid on the sealing cover 4 (or 4A), the rubber sealing ring 3 is installed on the sealing cover 4 (or 4A), the sail type fin 2 Installed on the heat collecting section 7 of the heat pipe 6 (or 6A), the sealing cover 4 (or 4A) is installed on the top of the heat pipe 6 (or 6A) near the sail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com