Non-contact laser displacement measurement system used for cement-based materials

A cement-based material, laser displacement technology, used in measuring devices, optical devices, instruments, etc., can solve the problems of calibration and calibration, poor test accuracy, and the time can only be after the initial setting of cement-based materials. The effect of high test accuracy and fast sampling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

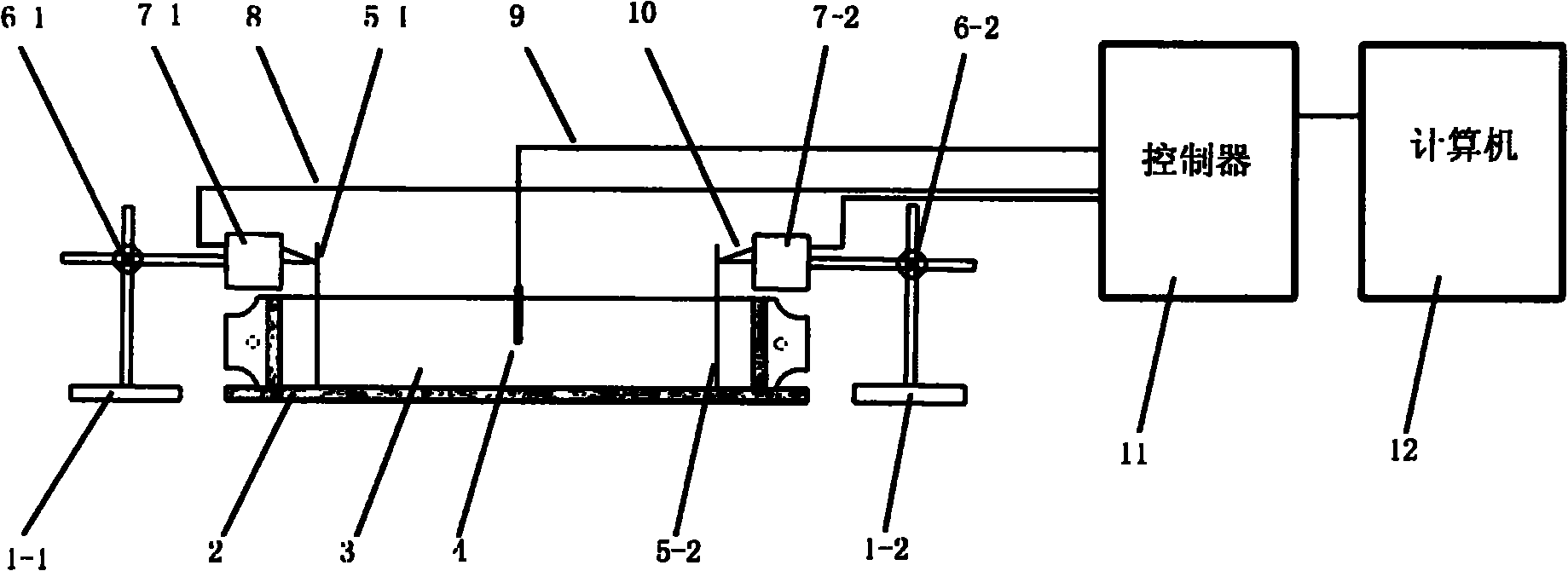

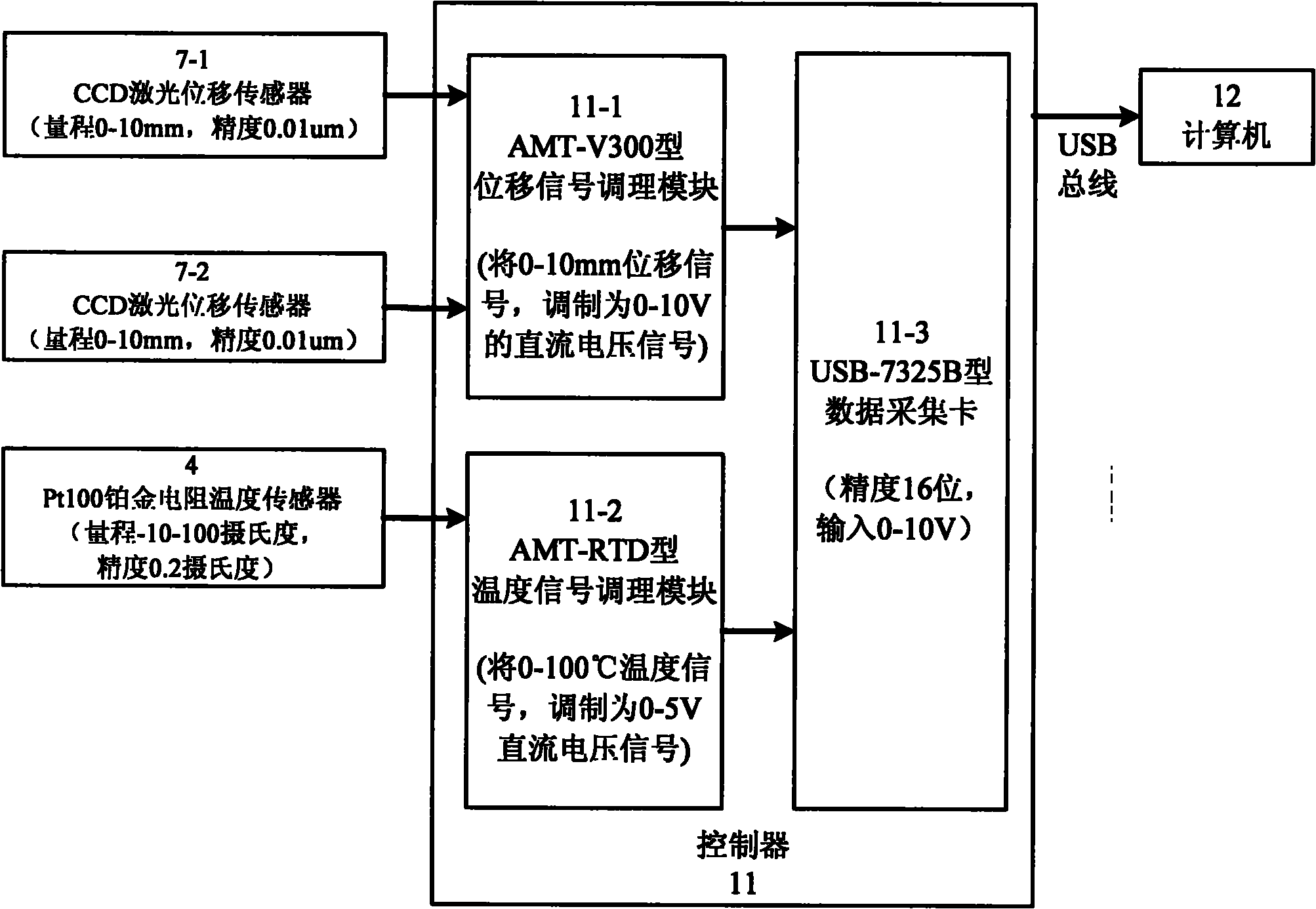

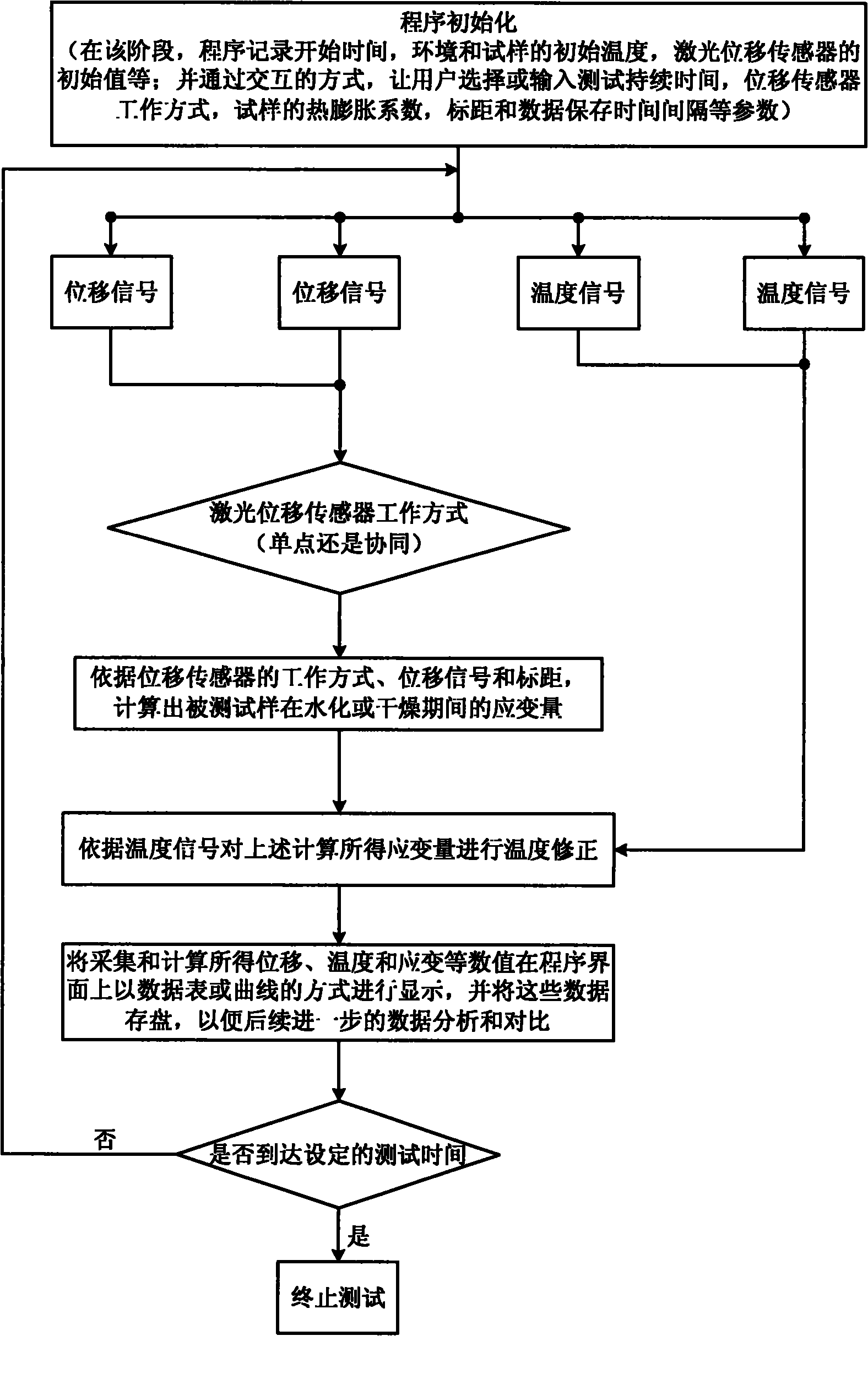

[0026] On the premise of analyzing the above-mentioned background technology, the present invention proposes a non-contact laser displacement measurement system for cement-based materials, using this device to test the displacement change history of cement-based materials during hydration and drying shrinkage . Its system architecture is attached figure 1 As shown, it consists of a laser displacement sensor fixing bracket 1, two left and right: 1-1 and 1-2, a cement-based material molding mold 2, a tested cement-based material sample 3, and a temperature sensor 4. The laser signal reflection target 5 in the tested cement-based material sample 3, there are two left and right: 5-1 and 5-2, installed on the horizontal and vertical positions of the laser displacement sensor fixing bracket 1 Adjustment knob 6, two left and right: 6-1 and 6-2, laser displacement sensor 7, two left and right: 7-1 and 7-2, optical path beam 10 of the laser signal, the laser displacement sensor 7 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com