Main steam pressure tracking optimization method for steam turbine

A technology of main steam pressure and optimization method, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving accuracy, improving economy, and improving optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

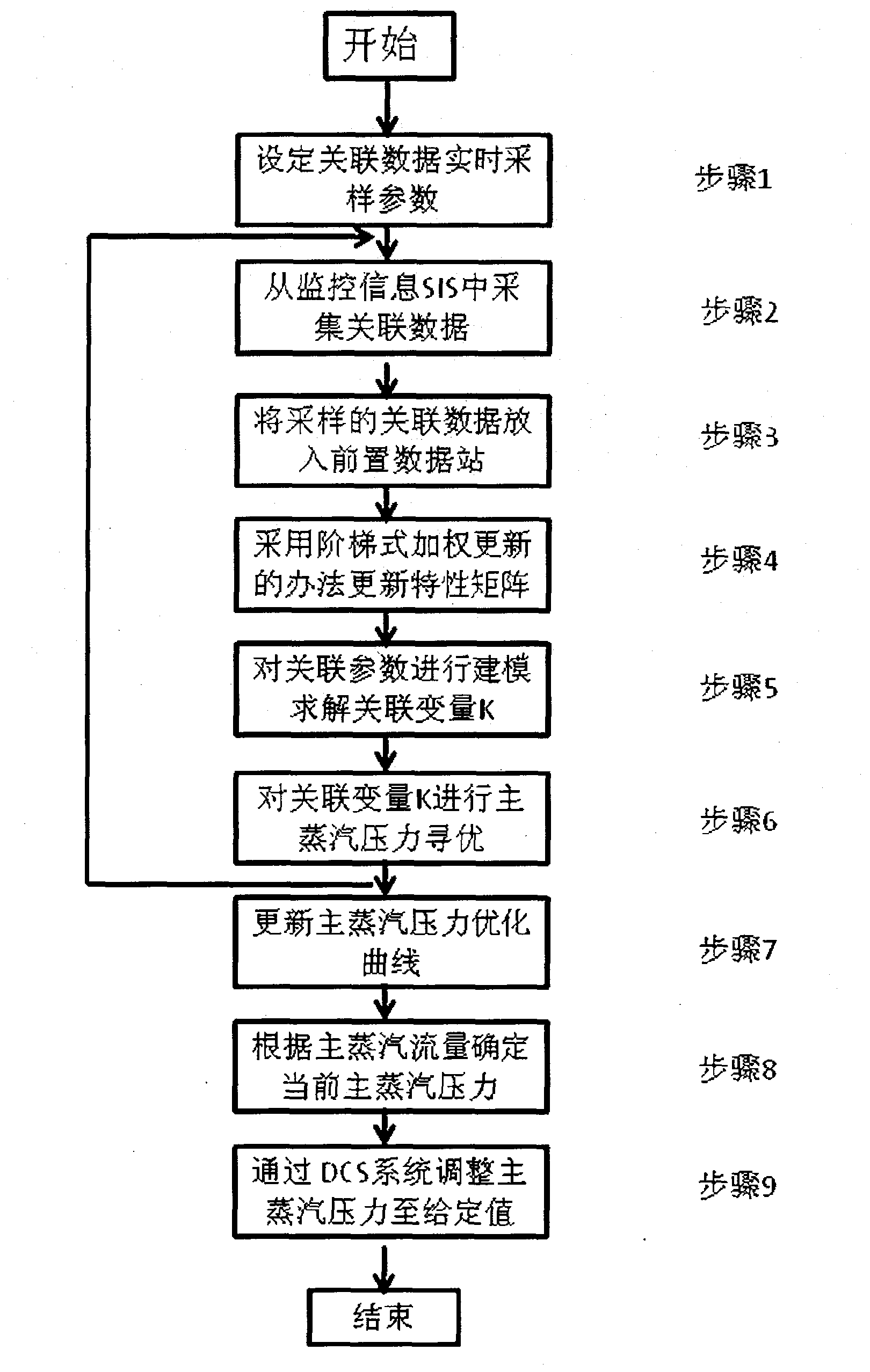

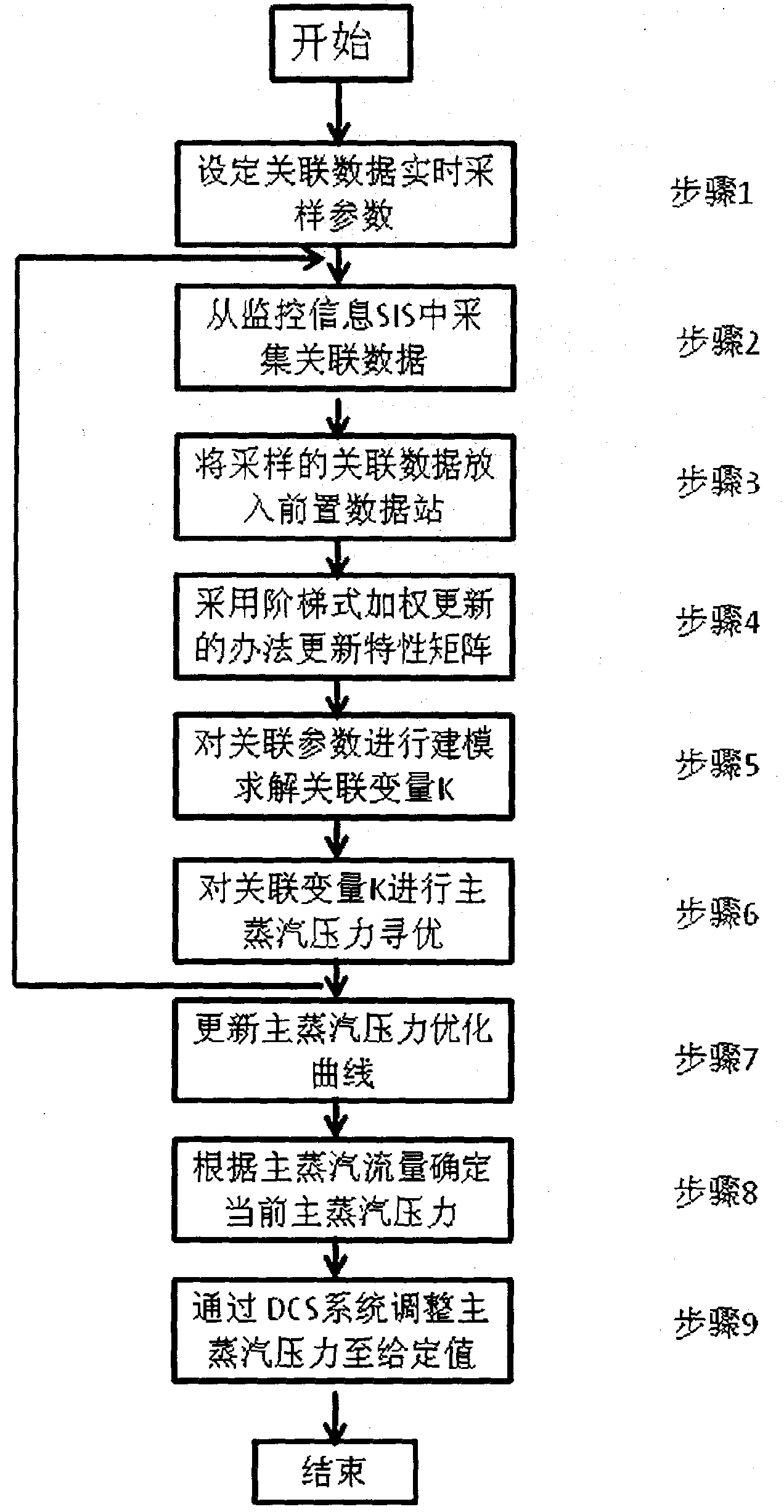

[0018] The steam turbine main steam pressure tracking optimization method of the present invention mainly comprises the following steps:

[0019] (1) Set related data acquisition related parameters;

[0020] (2) Regularly select data groups from the real-time sampling data of the SIS system of the steam turbine monitoring information system:

[0021] B={D, P1, T1, P2, T2, n (or I), Pb}, where D is the main steam flow rate, P1 is the main steam pressure, T1 is the main steam temperature, P2 is the high pressure cylinder exhaust pressure, T2 is the exhaust temperature of the high-pressure cylinder, n is the speed of the small steam turbine (for the unit whose feedwater pump is an electric pump, I is the current of the electric feedwater pump), and Pb is the back pressure of the condenser.

[0022] (3) Put data group B into the front data station;

[0023] (4) Using [D, P1] as the coordinates, the data in the front data station is weighted to update the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com