Single-side welding equipment

A single-sided welding and welding line technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as shaking and adverse effects of welding parts, and achieve the effect of stable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

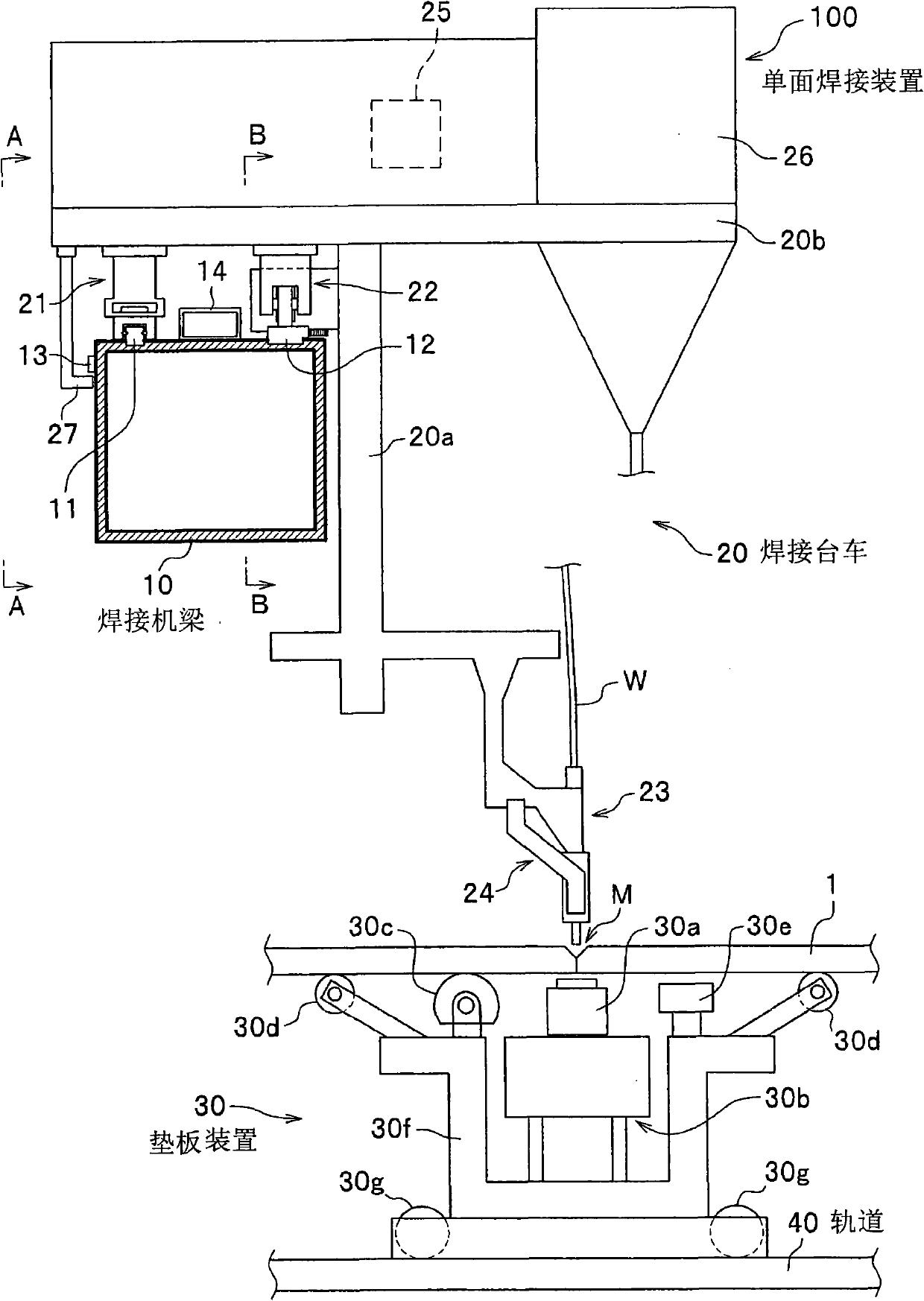

[0030] Next, the single-side welding device 100 according to the embodiment will be described with reference to the drawings.

[0031] like figure 1 As shown, the single-sided welding device 100 mainly includes a welding machine beam 10 , a welding trolley 20 suspended and supported in a cantilever state along the side surface of the welding machine beam 10 , and a backing plate device 30 arranged on the back side of the flux line M.

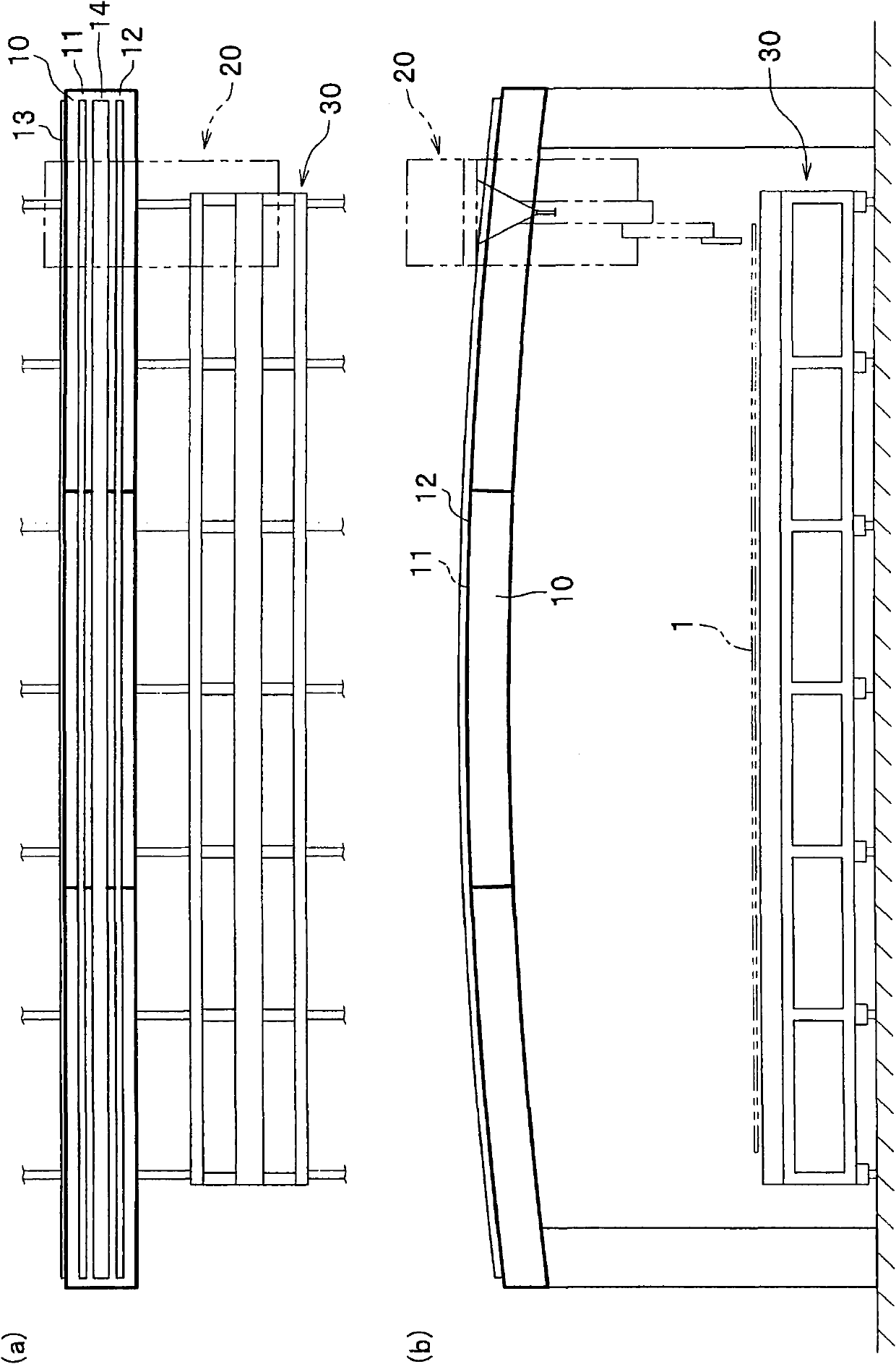

[0032] like figure 1 , image 3 As shown in (a), the welding machine beam 10 is a linearly formed frame for supporting the welding trolley 20 in a traveling manner. The welding beam 10 is formed in a hollow square pipe shape, and is made of, for example, a metal material. In addition, the welding machine 10 is substantially parallel to the welding line M for aligning the member to be welded 1 , and is formed in an elongated shape longer than the member to be welded 1 by joining a plurality of beam pieces.

[0033] like figure 1 , image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com