Damping generation method through torsion type lead extrusion and damper thereof

A production method and damper technology, applied in building components, shockproof, etc., can solve problems such as energy consumption, and achieve the effects of strong energy consumption, convenient processing, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

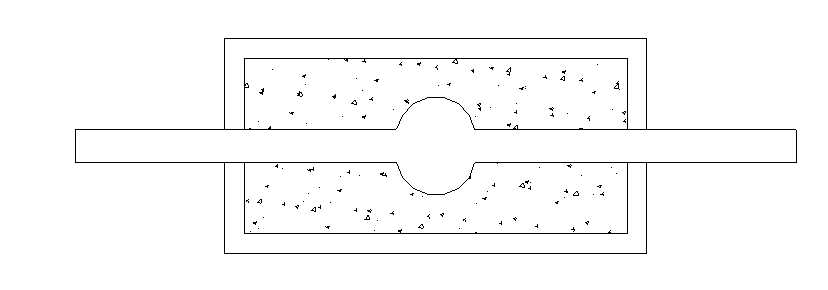

[0059] A method for generating damping in torsional lead extrusion. Take a closed cavity 1 and fill the closed cavity 1 with a damping material 2; the closed cavity 1 runs through the central rotating shaft 3 and forms a rotational connection with the closed cavity 1. A flange 4 is arranged on the central rotating shaft 3 and embedded in the damping material 2 .

Embodiment 2

[0061] A torsional lead extrusion damper includes a closed cavity 1 filled with lead 2 and a central shaft 3, the central shaft 3 passes through the closed cavity 1, and a flange 4 is arranged on the central shaft 3. A rotating gear 5 is provided at the end of the central rotating shaft 3 outside the closed cavity 1 , and a translation rack 6 is meshed on the rotating gear 5 .

[0062] The number of flanges (4) is variable, or they form a certain angle of intersection, and the central rotating shaft 3 can be multiple, refer to Figure 11 , Figure 12 , the number of flanges 4 on each central rotating shaft 3 is 2, and the number of central rotating shafts 3 is 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com