Anti-abrasion device for drill pipe and casing pipe

A wear-proof device and casing technology, used in geological drilling and oil fields, can solve the problems of increasing unsafe factors and dangers, drill pipe tripping, and no rolling bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

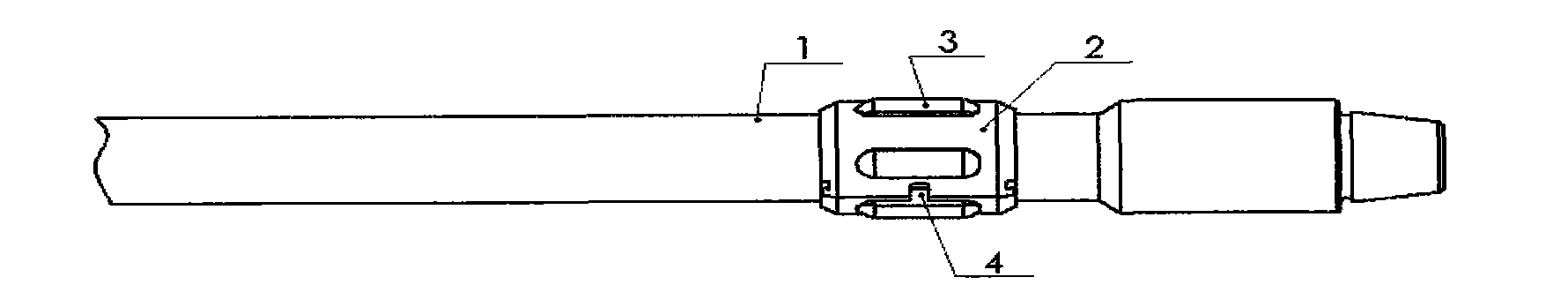

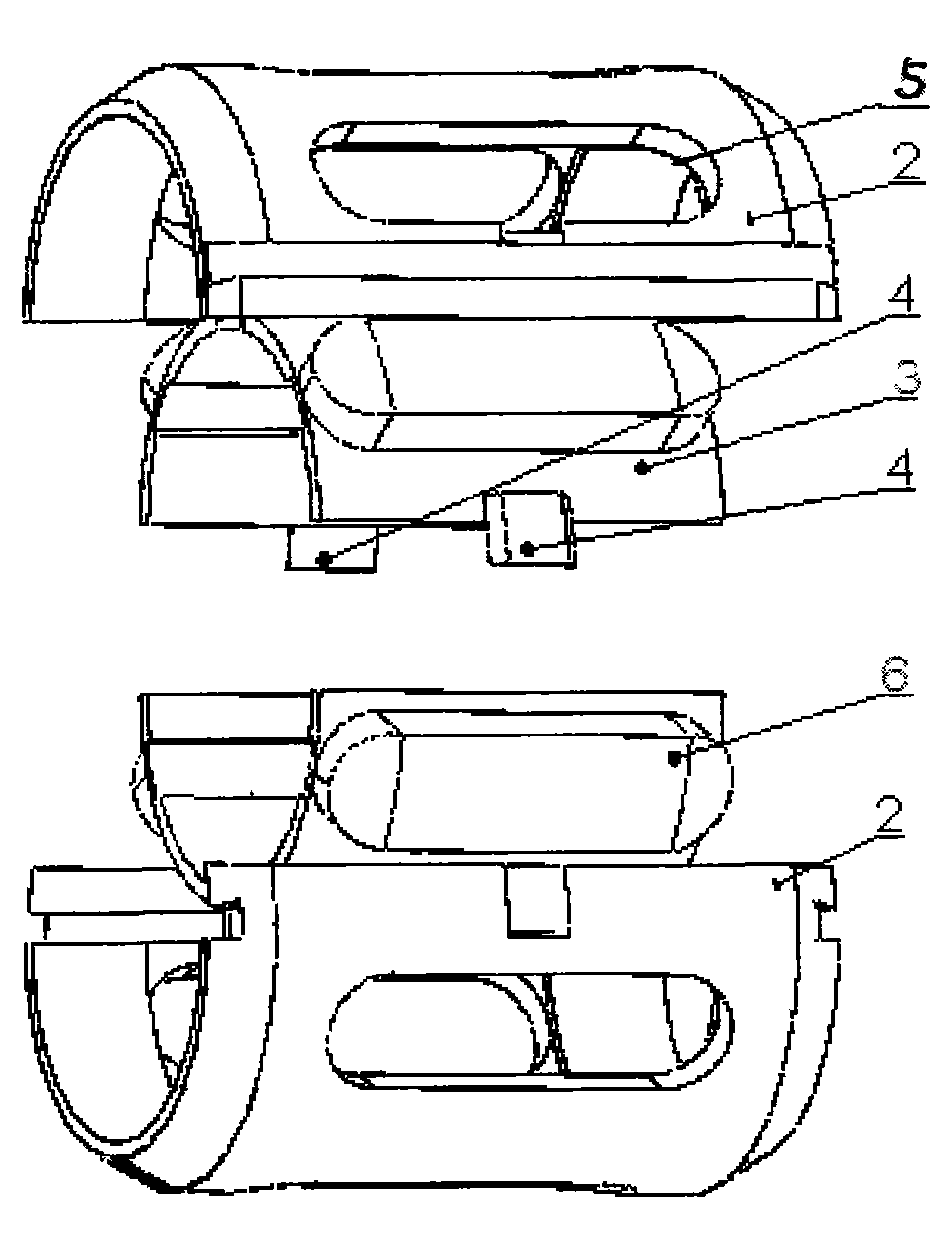

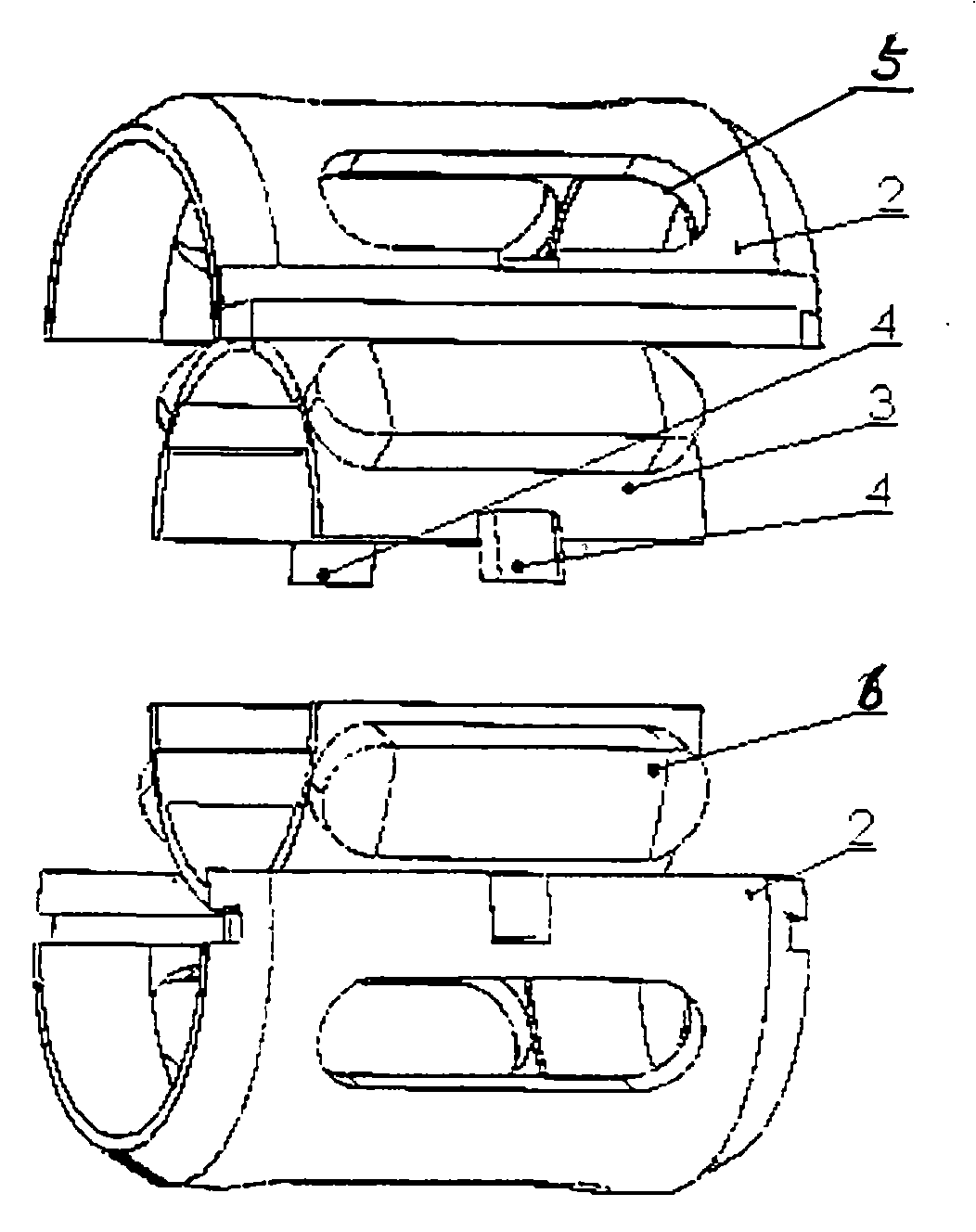

[0014] The anti-wear device is a new type of drill string hoop set on the drill pipe 1. It is composed of two halves of high-strength alloy steel skeletons 2, two halves of anti-wear rubber sleeves 3 and two lock blocks 4. The two are semi-cylindrical. The two sides of the shaped high-strength alloy steel skeleton 2 are respectively provided with dovetail chute and slide bar that can slide in and fasten in the axial direction, and can slide in and fasten in the axial direction from different ends to form a cylinder 4 oblong holes 5 are milled out in the middle of the cylindrical skeleton, and there are two small dovetail slots in the fastening gap, and there are two semi-cylindrical anti-corrosion slots in the high-strength alloy steel skeleton 2. Grinding rubber sleeve 3, there are 4 oblong ribs 6 corresponding to the oblong holes on the high-strength alloy steel skeleton 2 outside the circumference of the anti-wear rubber sleeve 3, the shape and distribution of the oblong rib...

Embodiment 2

[0016] The anti-wear device is a new type of drill string hoop set on the drill pipe 1. It is composed of two halves of high-strength alloy steel skeletons 2, two halves of anti-wear rubber sleeves 3 and two lock blocks 4. The two are semi-cylindrical. The two sides of the shaped high-strength alloy steel skeleton 2 are respectively provided with dovetail chute and slide bar that can slide in and fasten in the axial direction, and can slide in and fasten in the axial direction from different ends to form a cylinder 7 oblong holes 5 are milled out in the middle of the cylindrical skeleton, and there are two small dovetail slots in the fastening gap respectively. There are two semi-cylindrical anti-corrosion slots in the high-strength alloy steel skeleton 2 correspondingly. Grinding rubber sleeve 3, there are 7 oblong ribs 6 corresponding to the oblong holes on the high-strength alloy steel skeleton 2 outside the circumference of the anti-wear rubber sleeve 3, the shape and distr...

Embodiment 3

[0018] The anti-wear device is a new type of drill string hoop set on the drill pipe 1. It is composed of two halves of high-strength alloy steel skeletons 2, two halves of anti-wear rubber sleeves 3 and two lock blocks 4. The two are semi-cylindrical. The two sides of the shaped high-strength alloy steel skeleton 2 are respectively provided with dovetail chute and slide bar that can slide in and fasten in the axial direction, and can slide in and fasten in the axial direction from different ends to form a cylinder 5 oblong holes 5 are milled in the middle of the cylindrical skeleton, and there are two small dovetail slots in the fastening gap, and there are two semi-cylindrical anti-corrosion holes in the high-strength alloy steel skeleton 2. Grinding rubber sleeve 3, there are 5 oblong ribs 6 corresponding to the oblong holes on the high-strength alloy steel skeleton 2 outside the circumference of the anti-wear rubber sleeve 3, the shape and distribution of the oblong ribs 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com