Controllable multiple-pulse gas generator device

A gas generation and multi-pulse technology, which is used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve problems such as difficulty in closing, and achieve the effect of delaying the closing time and facilitating construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

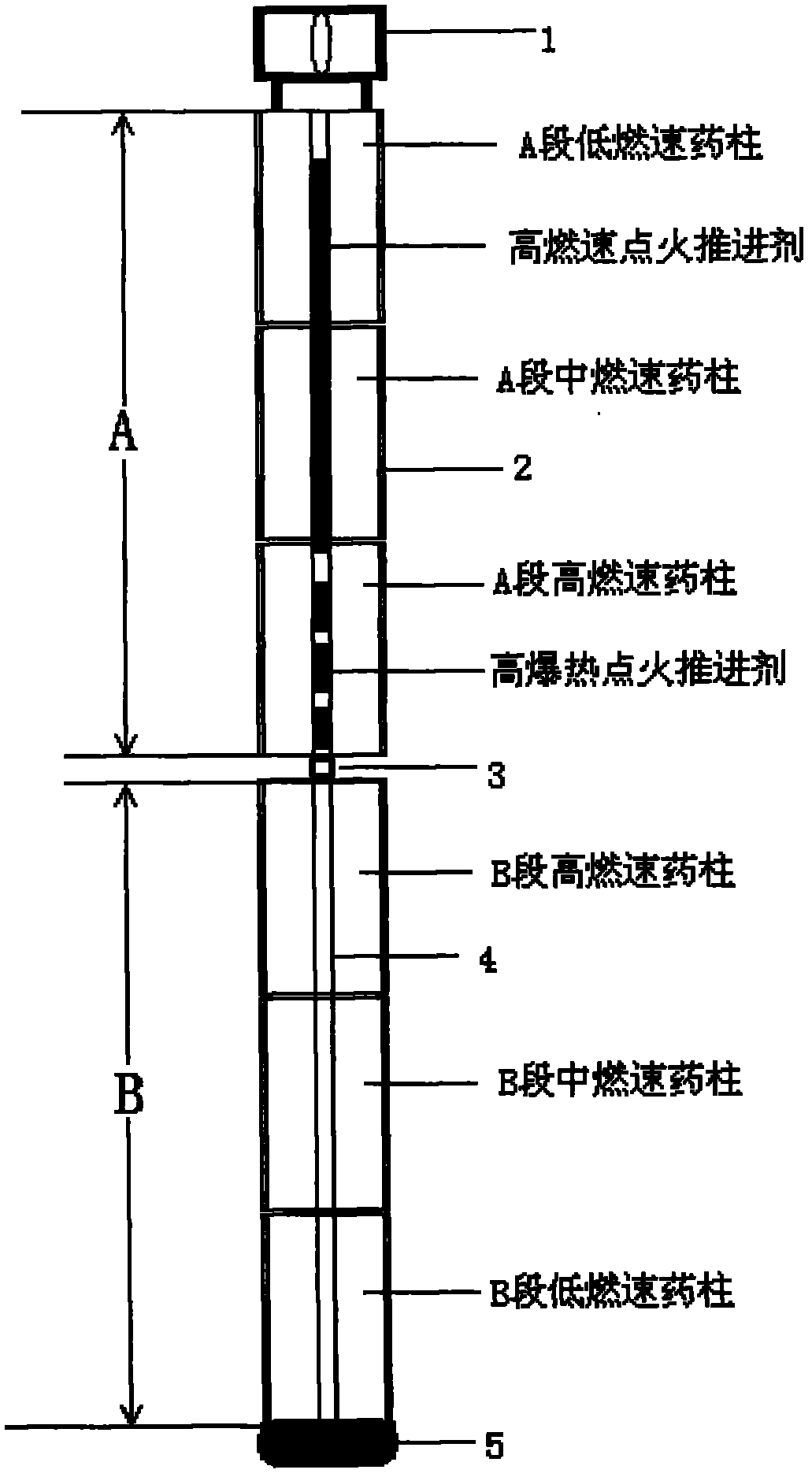

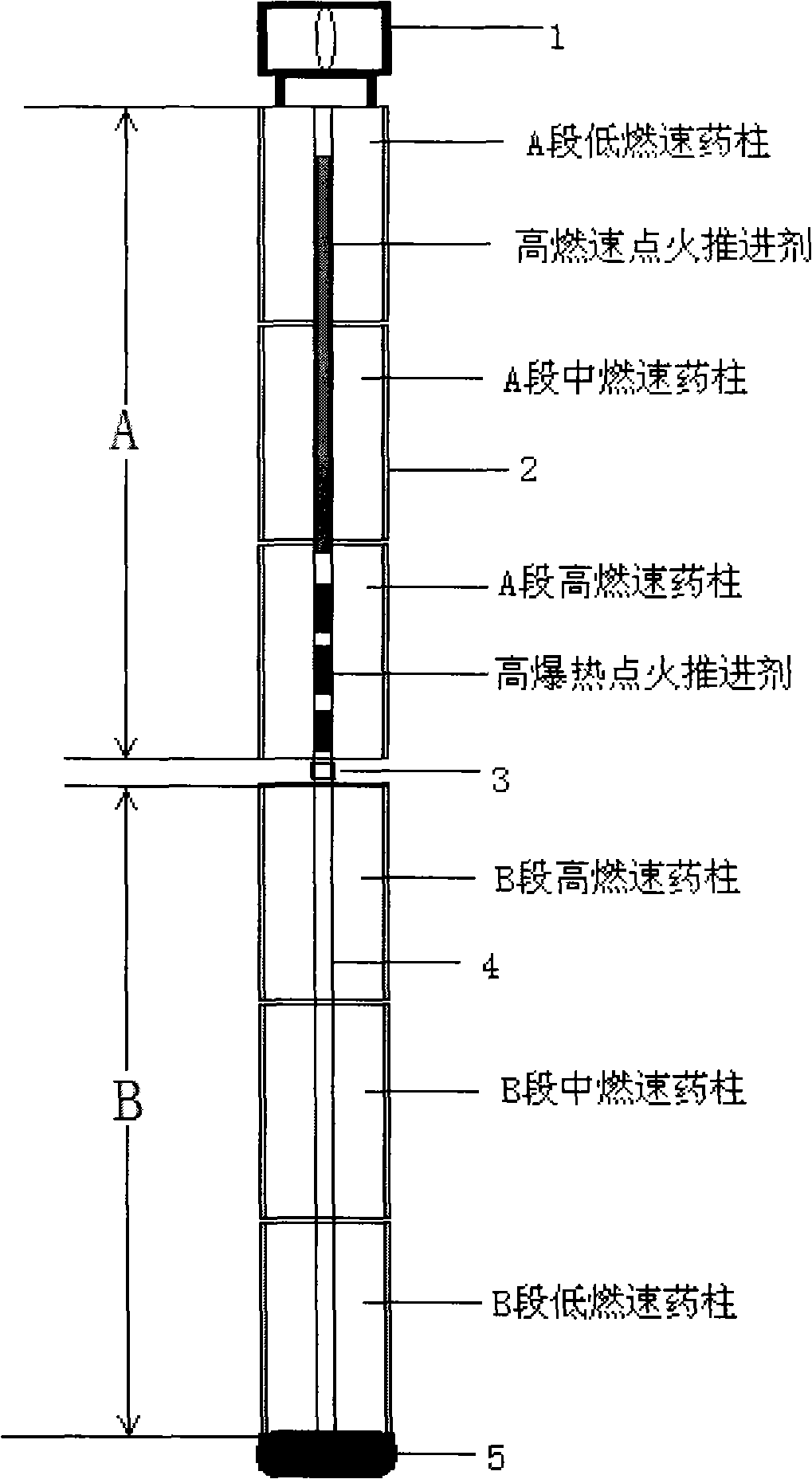

[0011] Such as figure 1 As shown, the device of the present invention is composed of an igniter 1, a section A high-alumina and high-chlorine propellant grain, a B-section high-alumina and high-chloride propellant grain, a plugging joint 3, and a centralizer 5. The high-alumina and high-chlorine propellant grains in sections A and B are each Φ84×3000mm, and the plugging joint 3 is used to ensure that the high-temperature and high-pressure airflow after the ignition propellant in the center tube 4 of section A will not leak into the center tube 4 of the grain column in section B. Ensure that the A-stage high-alumina and high-chlorine propellant grains burn first, and the B-stage high-burning-rate propellant grains burn later, so as to form more pressure pulses, that is, the number of pulses is controllable. The centralizer 5 is used to ensure that the shell of the drug column is not damaged by casing wall friction during the whole device going downhole. Φ86×50mm.

[0012] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com