Grating magnetic scale displacement sensor

A technology of displacement sensor and magnetic ruler, applied in the field of displacement sensor, can solve the problems of serious wear, can not meet the needs of production, infiltration, etc., and achieve the effect of high measurement accuracy, improved accuracy and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

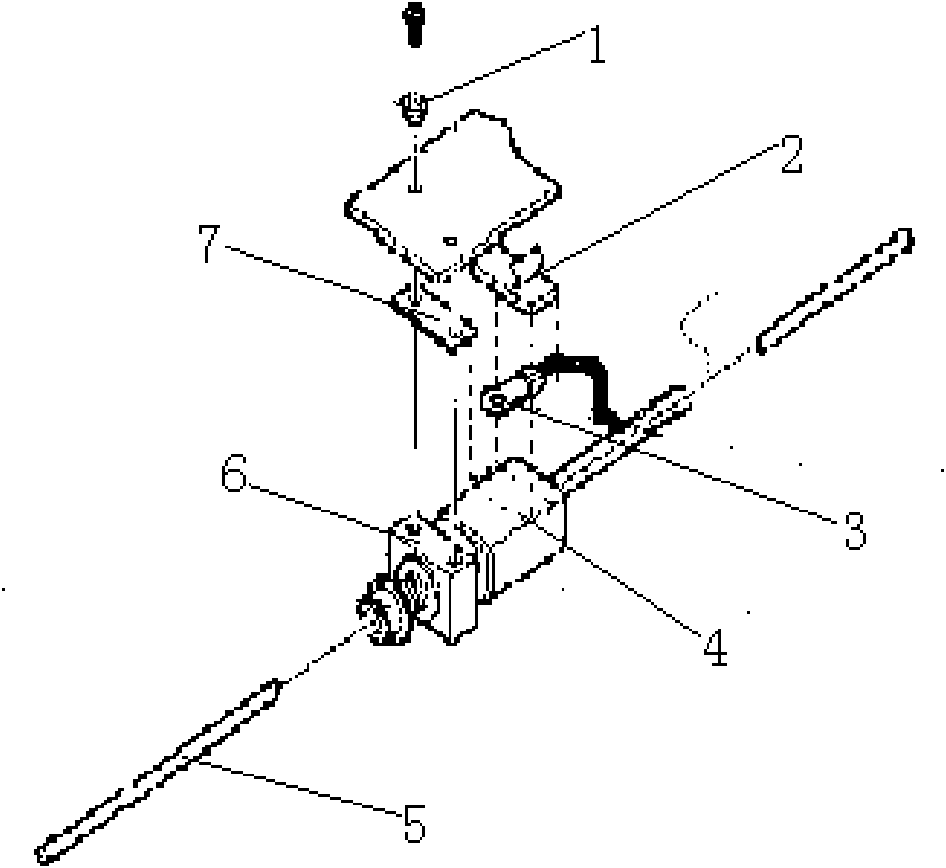

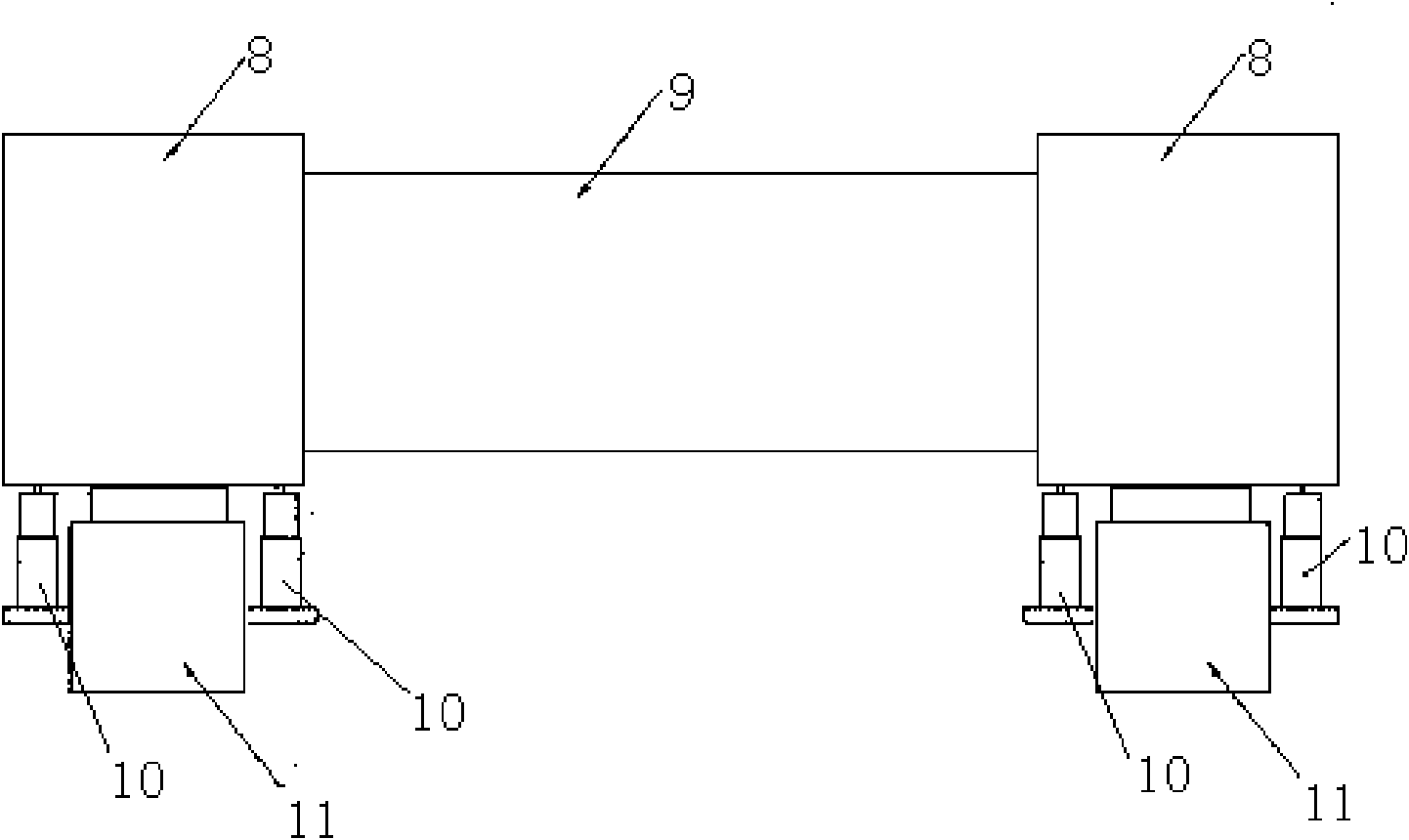

[0010] refer to figure 1 , one end of the holder (6) is connected to the grating magnetic ruler (5), the grating magnetic ruler (5) is connected to the crimp terminal (3), the other end of the holder (6) is connected to the probe (4), and through the holder (6) The connection hole connects the insulating sheet (7) and the partition plate (2), and then connects and installs the insulating sleeve (1) to assemble into one body. During use, the present invention is installed in the fixed displacement sensor (10) outside the pressing upper cylinder (11) of the rolling mill that is formed by supporting roller bearing (8), supporting roller (9), and pressing the upper cylinder (11), i.e. It can be put into testing operation, press the upper cylinder to push the supporting roller bearing box to move up and down, and the magnetic scale also moves with the bearing box, the probe measures the grating scale on the magnetic scale, and the read data is fed back to the control system. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com