Vacuum treatment method of external-expander capacitive voltage transformer

A technology of voltage transformer and vacuum treatment, applied in the direction of transformer/inductor cooling, inductors, circuits, etc., can solve the problems of oil leakage between bushing flange and cover, product performance increase, difficult to replace, etc., to reduce The effect of labor intensity, quality improvement and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

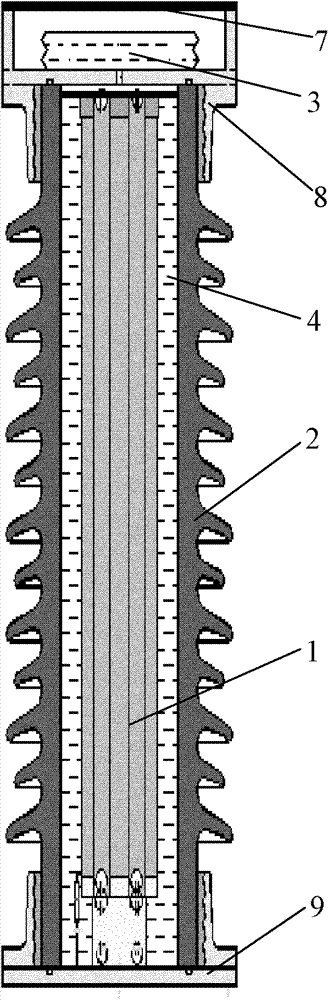

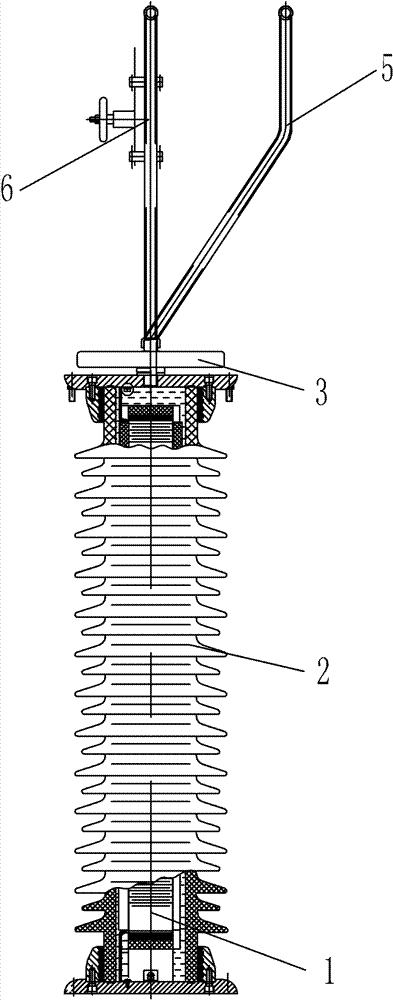

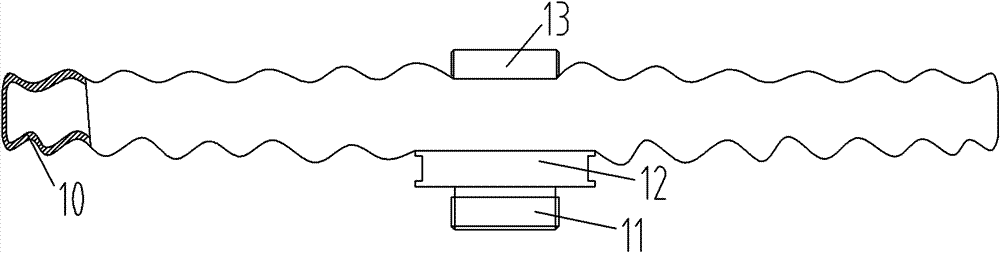

[0019] see figure 1 , the external expander type capacitor voltage transformer of the present invention includes a bushing 2 , a core 1 and an expander 3 . The core 1 is set in the casing 2 and sealed by the upper and lower covers 8 and 9 at both ends of the casing 2 , the expander 3 is arranged on the upper end of the cover 8 on the casing 2 , and the casing 2 is filled with insulating oil 4 . In addition, an end cover 7 for covering and sealing the expander 3 is provided on the upper cover 8 . The present invention adopts an external expander structure such as image 3 As shown, it is a disc-shaped box body made of corrugated board 10. A lower connection port 12 and a connection nut 11 are provided at the center of the lower end of the disc-shaped box body, and an upper connection port 13 is provided at the center position of the upper end of the disc-shaped box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com