GaN-based LED epitaxial structure of inverted triangular barrier, and growth method thereof

An epitaxial structure, inverted triangle technology, applied in electrical components, nanotechnology, circuits, etc., can solve the problem of reducing photoelectric performance, can not improve the ability of hole injection and light-emitting layer limitation, can not better improve GaN-based blue LEDs Photoelectric performance and other issues, to achieve the effect of improving luminous efficiency and suppressing the quantum Stark effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

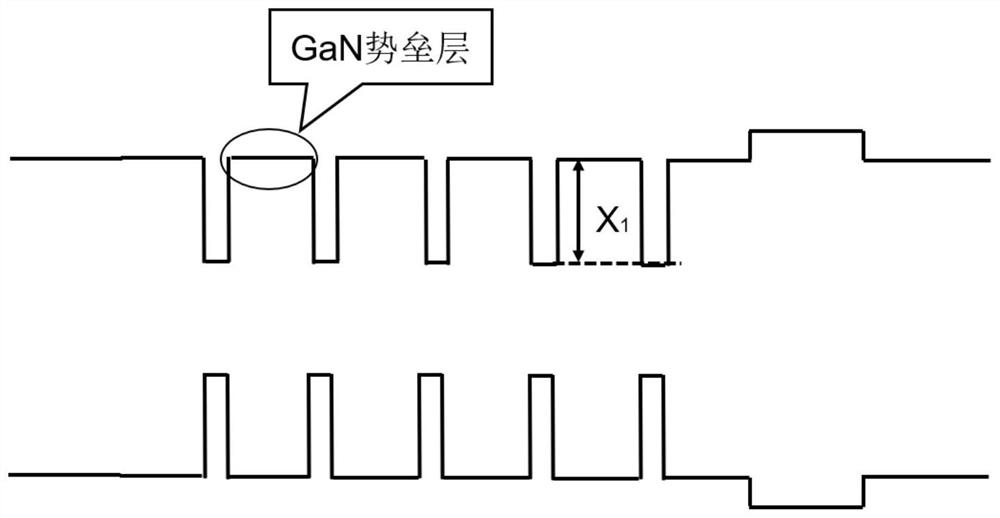

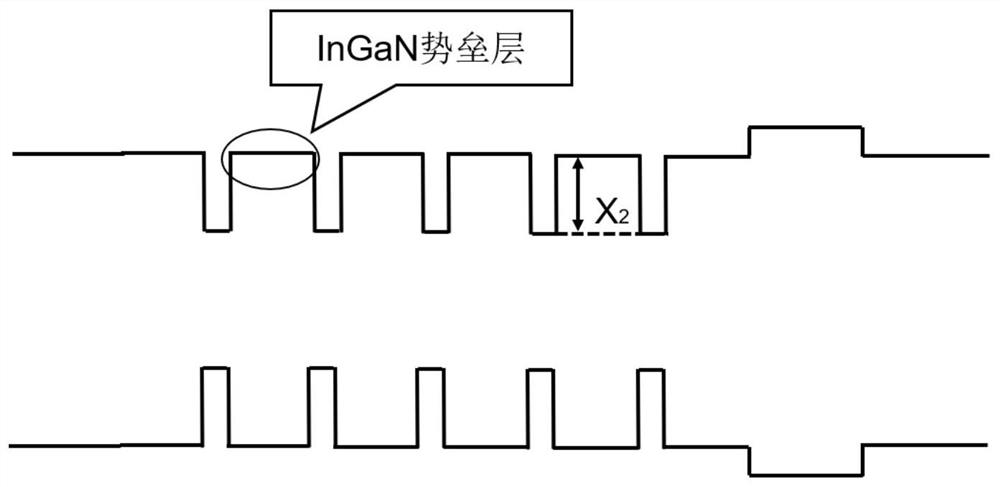

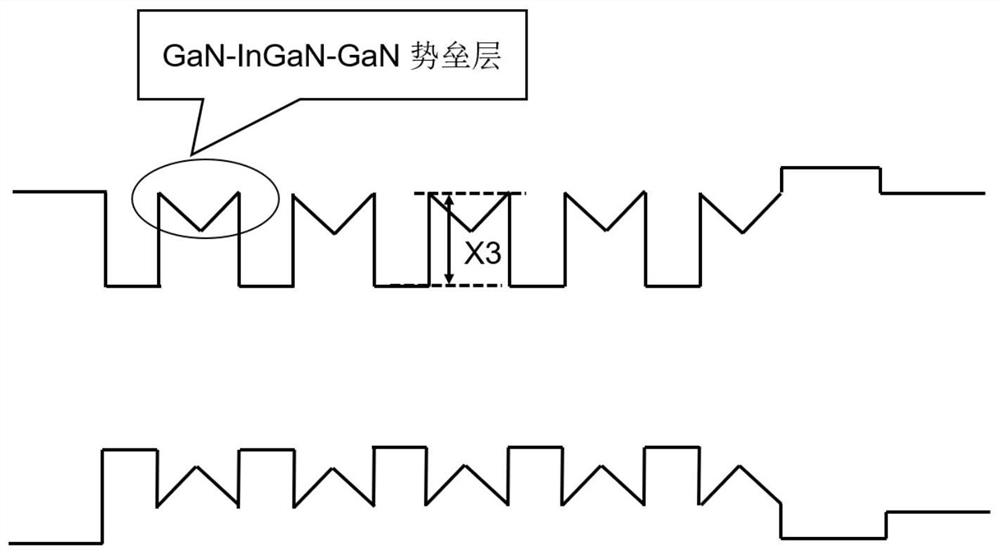

[0024] The invention replaces the GaN potential barrier in the light-emitting layer with a special GIG triangular potential barrier.

[0025] Depend on figure 1 , figure 2 and image 3 We can see that the growth of the GIG inverted triangular barrier layer, on the one hand, after introducing InGaN into the barrier layer, the application of InGaN material in the barrier layer can effectively reduce the polarization electric field between the barrier and the quantum well, and effectively suppress the The Tucker effect increases the effective radiative recombination rate of electrons and holes in quantum wells. On the other hand, after adopting the GIG inverted triangular barrier, compared with the traditional GaN barrier, the special barrier shape proposed by the present invention does not reduce the effective height of the barrier, and the inverted triangular barrier can still effectively confine carriers; Therefore, the photoelectric performance of the GaN-based LED is eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com