A cone-shaped shaker distributor

A distributor and cone technology, which is applied in the field of cone shaker distributor, can solve the problems of not being able to meet the needs of blast furnaces, exposure of transmission chains, failure, etc., and achieve the effects of reduced effective height, low production cost, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

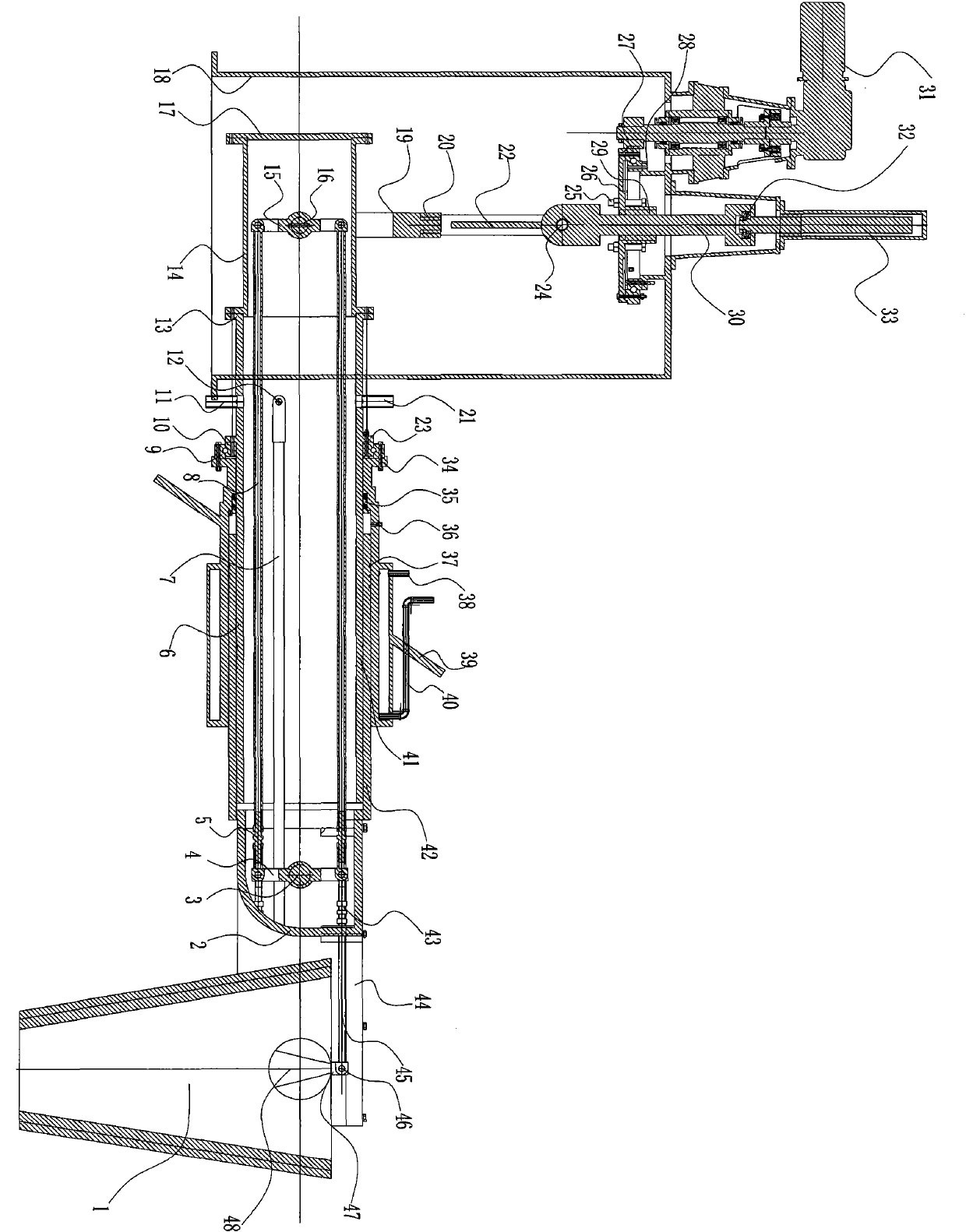

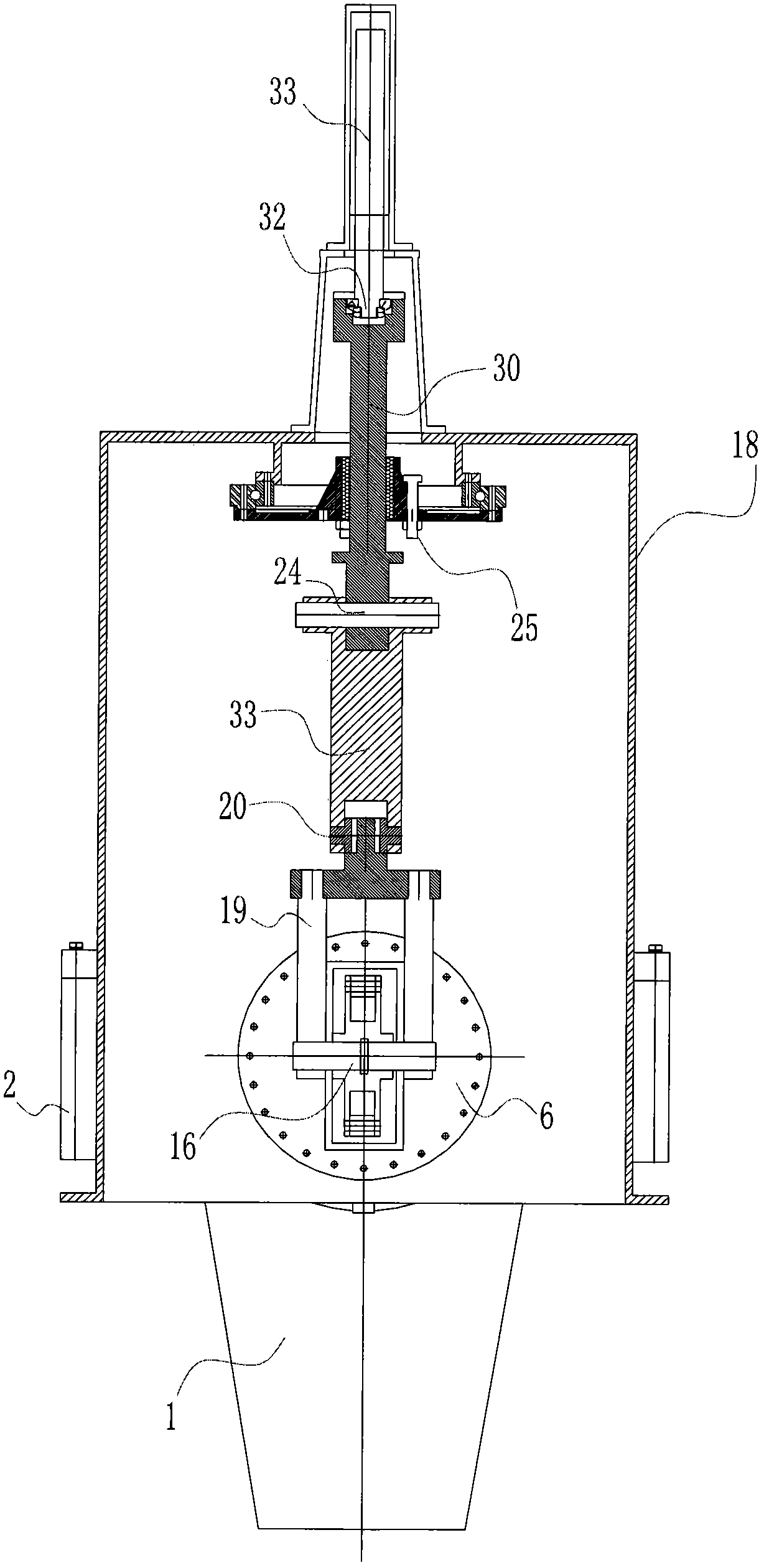

[0029] Such as Figure 1-11 As shown, the reference signs described in the embodiments of the present invention are as follows:

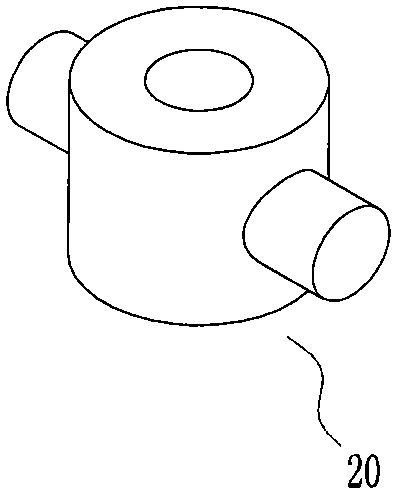

[0030]1 Cone barrel; 2 Hukou frame; 3 Intermediate shaft; 4 Intermediate shaft rocker arm; 5 Tie rod length adjustment bolt; 6 Main shaft; 7 Water inlet pipe; 8 Long tie rod; ;12 Water inlet; 13 Main shaft end flange; 14 Sub shaft box; 15 Sub shaft inner rocker arm; 16 Sub shaft; 17 Sub shaft box cover; 18 Transmission box; 22 crank; 23 main shaft middle flange; 24 transverse shaft; 25 limit bolt; 26 bearing base plate; 27 slewing bearing; 28 slewing bearing seat; Thrust bearing; 33 Oil cylinder; 34 Shaker slewing support seat; 35V seal assembly; 36 Oil cup; 37 Outer ring seal; 38 Drain outlet; Insertion pipe; 43 tie rod length adjustment bolt; 44 tiger mouth frame cover; 45 short tie rod; 46 pin shaft; 47 trunnion rocker arm; 48 trunnion; 51 first driving wheel; 52 first wire rope; Steel wire rope; 55 trunnion sheave; 61 second driving wheel; 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com