Thin film transistor array substrate, light-emitting panel and manufacturing method thereof as well as electronic device

A thin-film transistor and light-emitting panel technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of reduced manufacturing pass rate, increased influence of particles, and the probability of particle point defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the thin film transistor array substrate, the light-emitting panel, the manufacturing method thereof, and the electronic device according to the embodiments will be described in detail by showing the embodiments. First, a light emitting panel to which the thin film transistor array substrate of the embodiment and its manufacturing method are described. Here, a display panel in which a plurality of pixels including organic EL elements are arrayed will be described as a light emitting panel to which the thin film transistor array substrate of the embodiment is applied.

[0029] (luminescent panel)

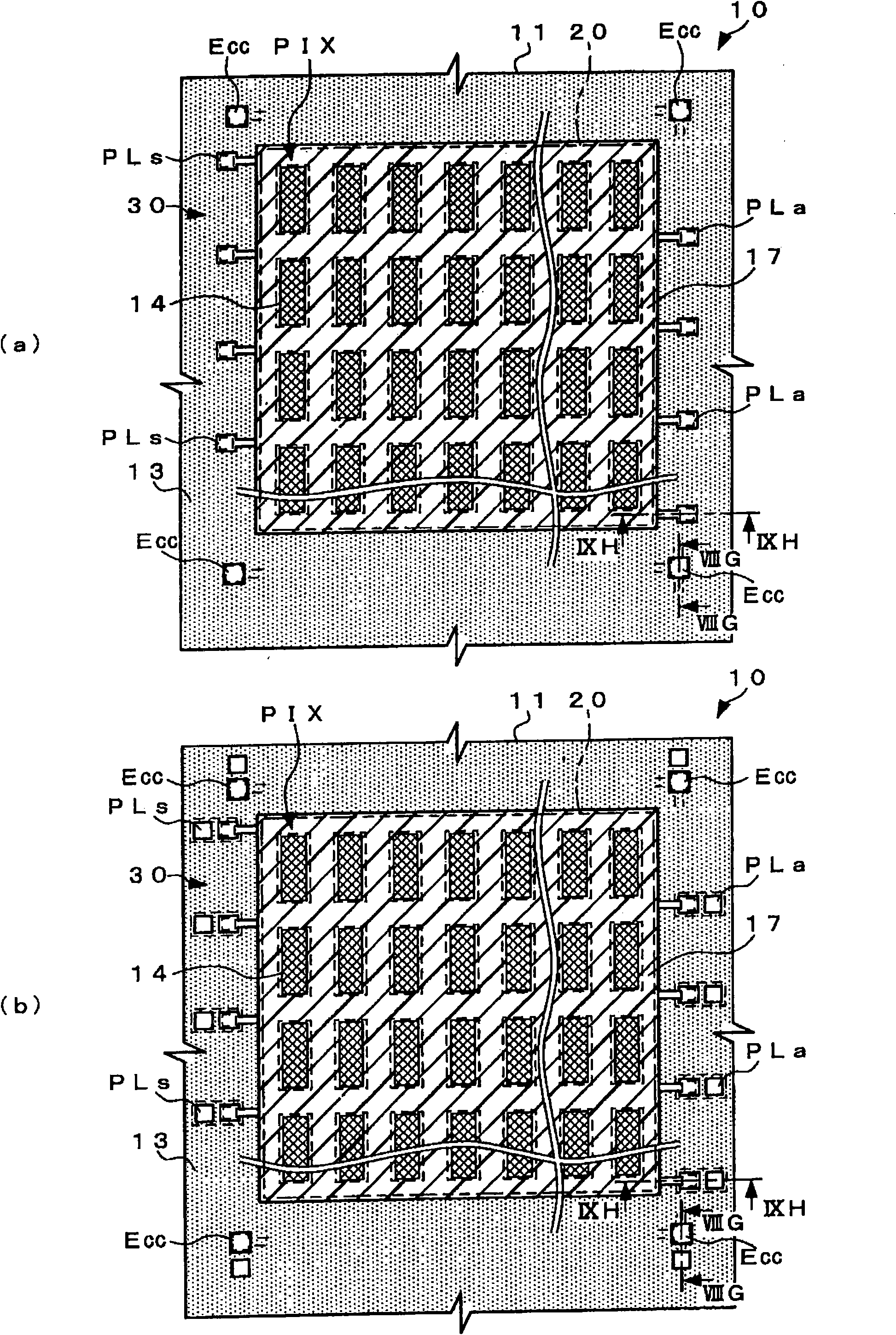

[0030] figure 1 A. figure 1 B is a schematic plan view showing an example of a display panel to which the thin film transistor array substrate of the embodiment is applied. figure 1 A is a schematic plan view showing a first example of a display panel, figure 1 B is a schematic plan view showing a second example of the display panel. also, figure 2 is showi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com