Array substrate and method for manufacturing same

An array substrate and manufacturing method technology, applied in the field of liquid crystal display, can solve problems such as increased process difficulty, insufficient alignment accuracy, and product yield decline, and achieve the effects of reducing manufacturing costs, increasing aperture ratio, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

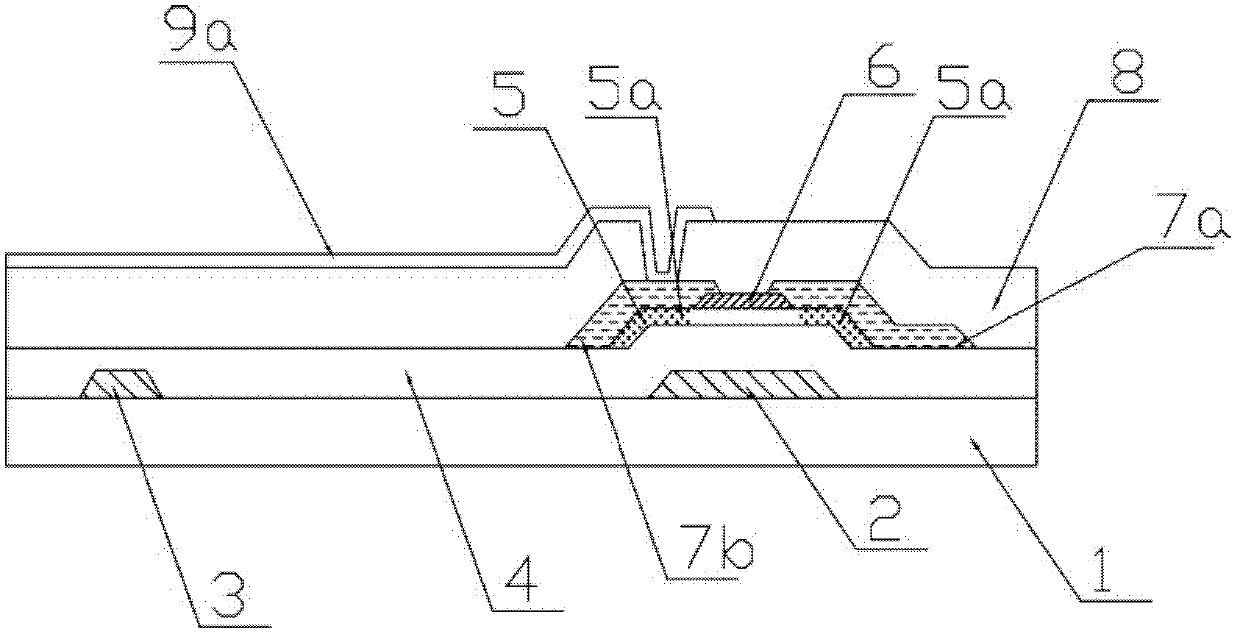

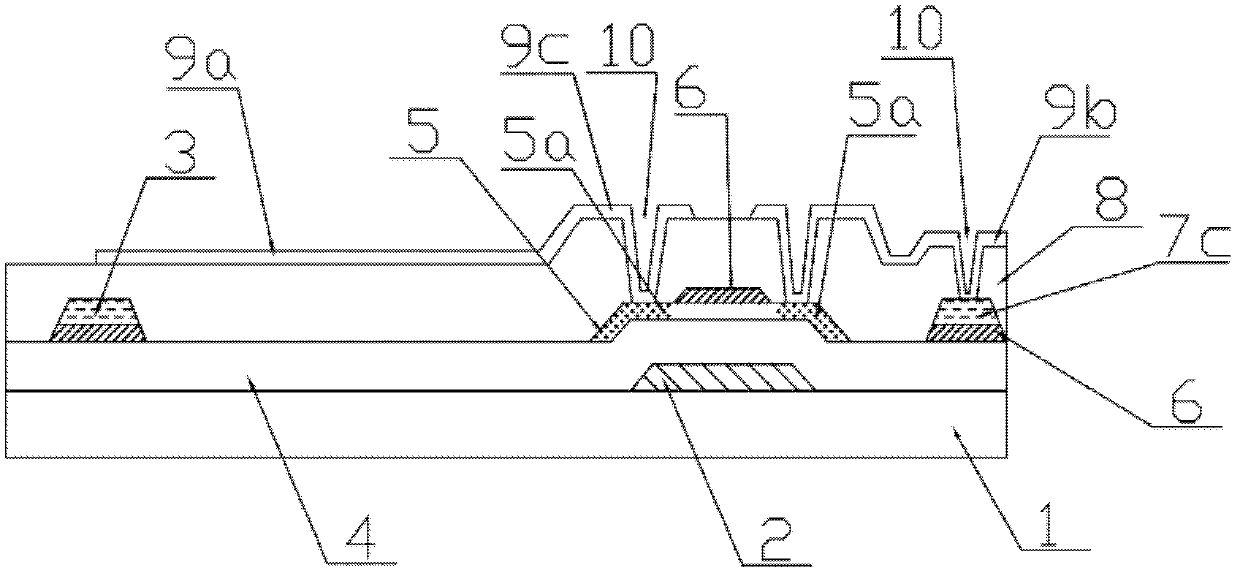

[0041] This embodiment provides an array substrate, including a substrate, a thin film transistor formed on the substrate, and a pixel electrode formed on the substrate, wherein the source and / or drain of the thin film transistor are made of a transparent conductive material. The thin film transistor may be a bottom gate type or a top gate type.

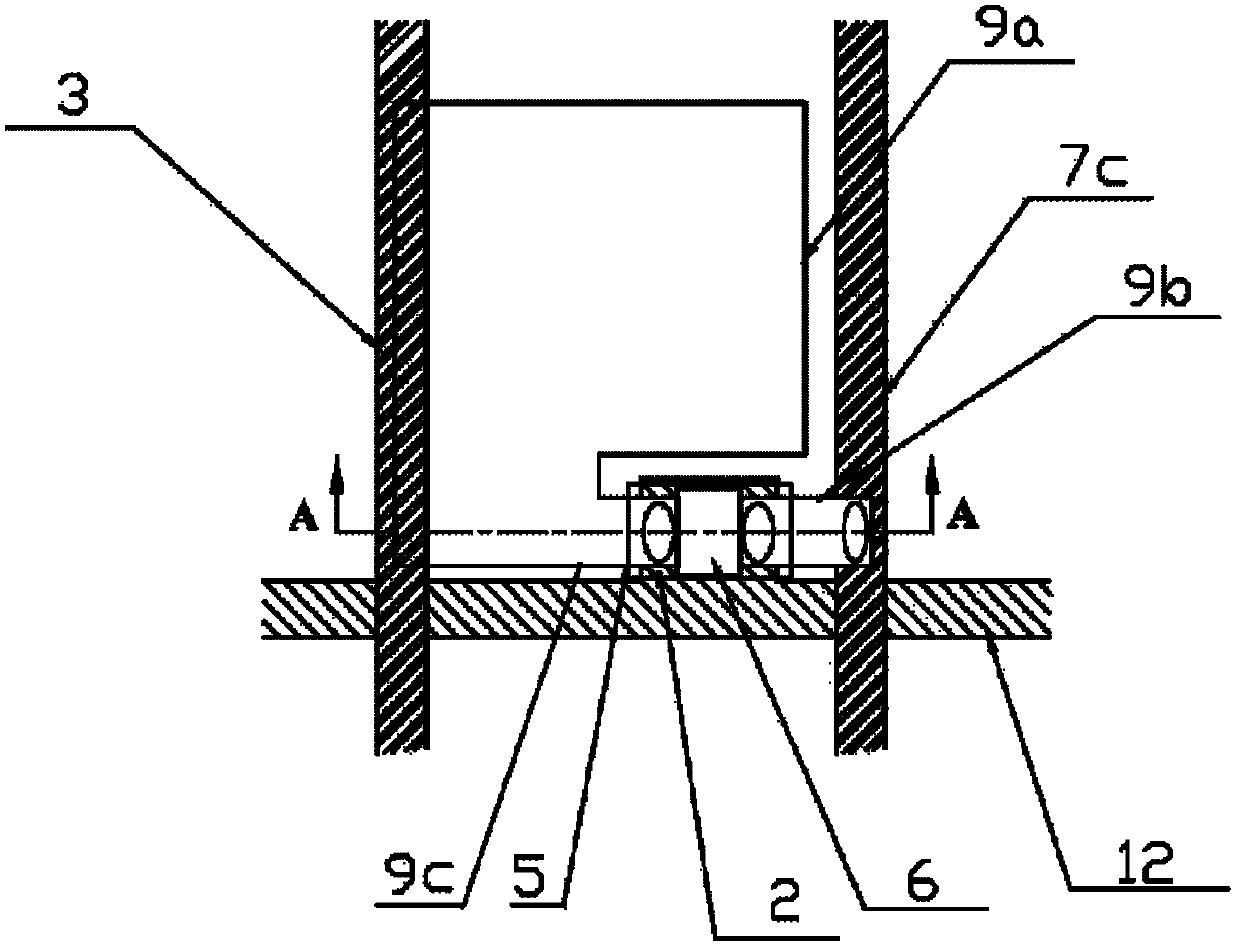

[0042] figure 2 It is a partial plan view (one of them) of a single pixel of the array substrate in this embodiment. On the transparent substrate 1, there are gate lines 12 and data lines 7c arranged vertically and intersecting each other, and a thin film transistor is arranged near the intersection point. The gate line 12 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com