Mechanically-agitating type liquid-replenishing device for wool-making groove

A liquid replenishing device and mechanical stirring technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, post-processing details, etc., can solve the problems affecting the stability of the texturing process, and ensure the quality of texturing, uniform concentration, and improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

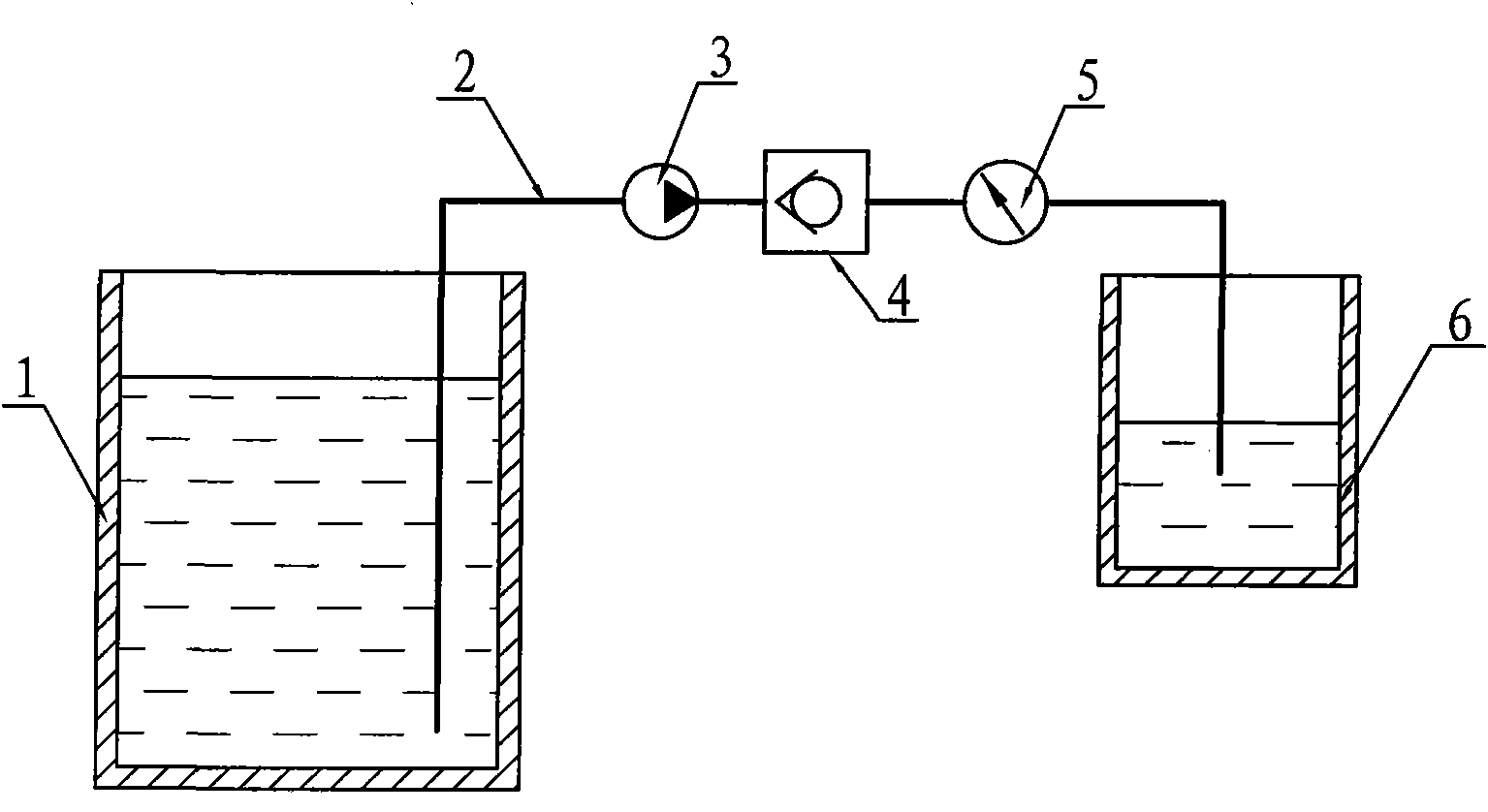

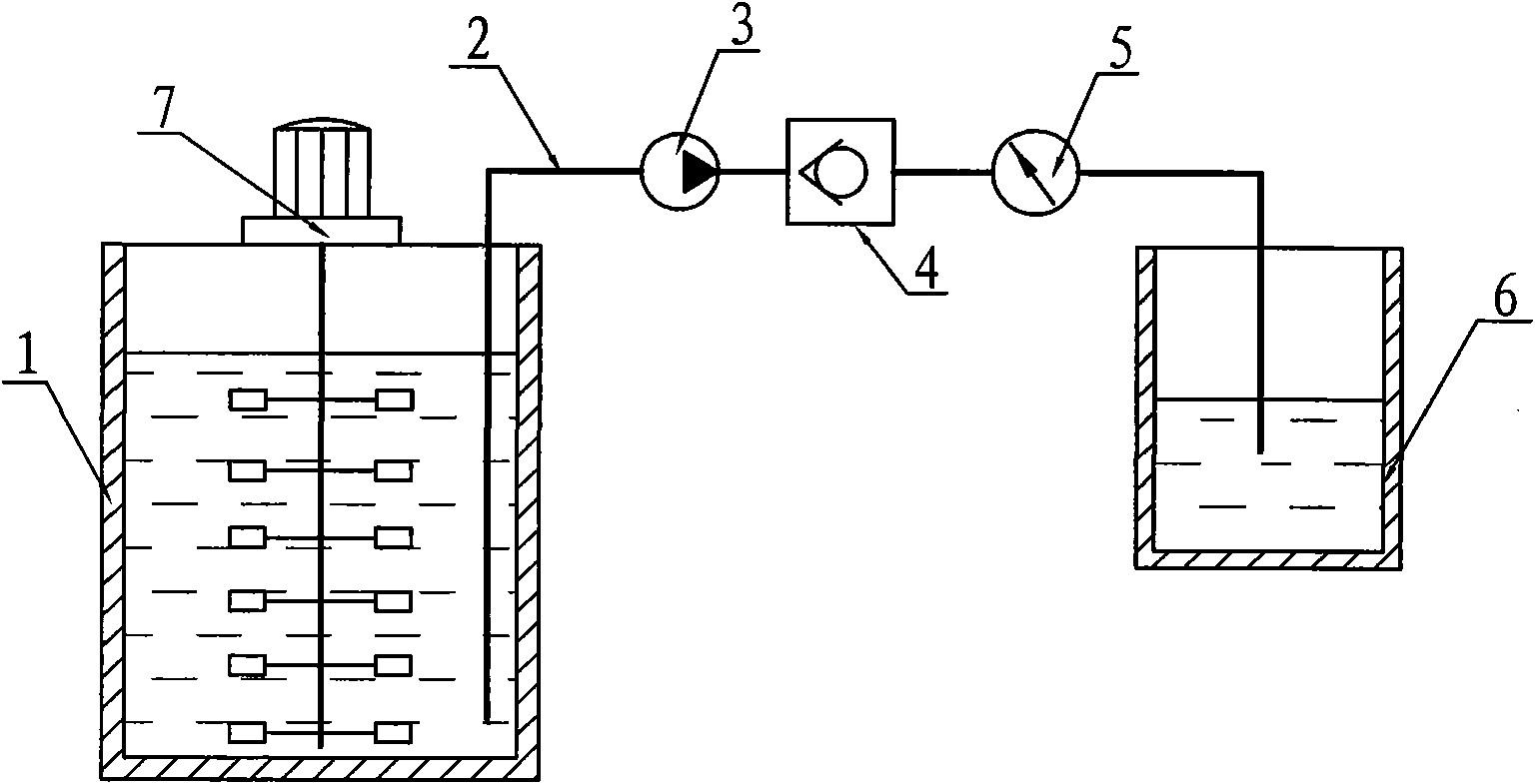

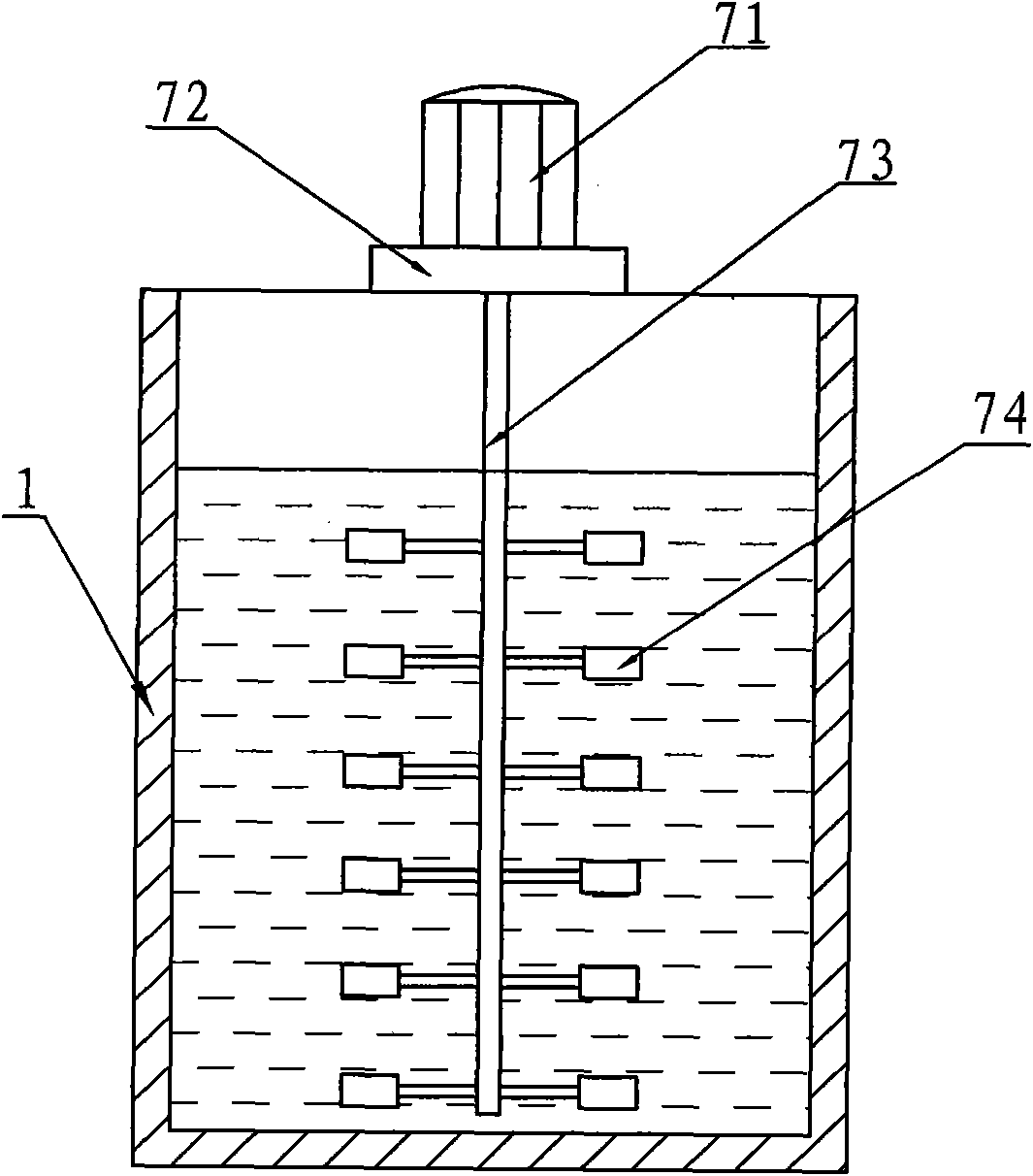

[0015] The mechanical agitation type cashmere tank replenishment device, such as figure 2 As shown, it includes liquid storage tank 1, infusion tube 2, infusion pump 3, one-way valve 4, flow meter 5 and cashmere tank 6, after infusion pump 3, one-way valve 4 and flow meter 5 are connected in series by infusion tube 2 Set between the liquid storage tank 1 and the texture tank 6, the liquid suction port of the liquid replenishment pump 3 is connected to the bottom of the liquid storage tank 1 through the infusion tube 2, and the liquid outlet of the flow meter 5 is connected to the texturing tank through the infusion tube 2. In the tank 6, an electric stirring rod 7 is provided in the liquid storage tank 1, and the electric stirring rod 7 is composed of a stirring motor 71, a support frame 72, a main shaft 73 and a blade 74, and the stirring motor 71 is fixed on the support frame 72, and the main shaft 73 is directly connected with the output shaft of the stirring motor 71, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com