Treatment ladle

A technology for ladle and ladle lining, applied in lighting and heating equipment, furnace components, furnaces, etc., to reduce wastage, improve magnesium recovery, and increase casting productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

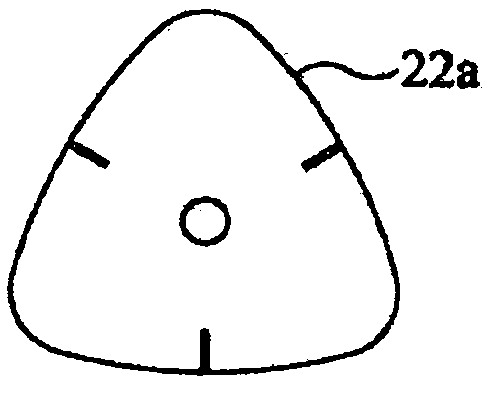

[0068] Example 1 ladle is shown in Figure 3A middle (vertical position) and Figure 3Band 3C (horizontal position). The interior space has a roughly triangular section. Comparative Example 1 is shown in Figure 4A (vertical position) and Figure 4B and 4C (horizontal position). The interior space has a circular section. Dashed lines are shown in each figure to demonstrate the level of molten metal when the ladle is filled to its capacity. A performance comparison of the two ladles is shown in the table below.

[0069]

Example 1

Comparative example 1

Work load (kg)

3000

3000

Total surface area of metal volume (mm 2 )

3719746

3892335

Top surface area (mm 2 )

1028446

1354917

Metal Height-Horizontal (mm)

417.7

427

Metal Height - Vertical (mm)

897

747

Geometric modulus (volume / surface area) (cm)

11.5

11

[0070] As the table shows, although t...

example 2

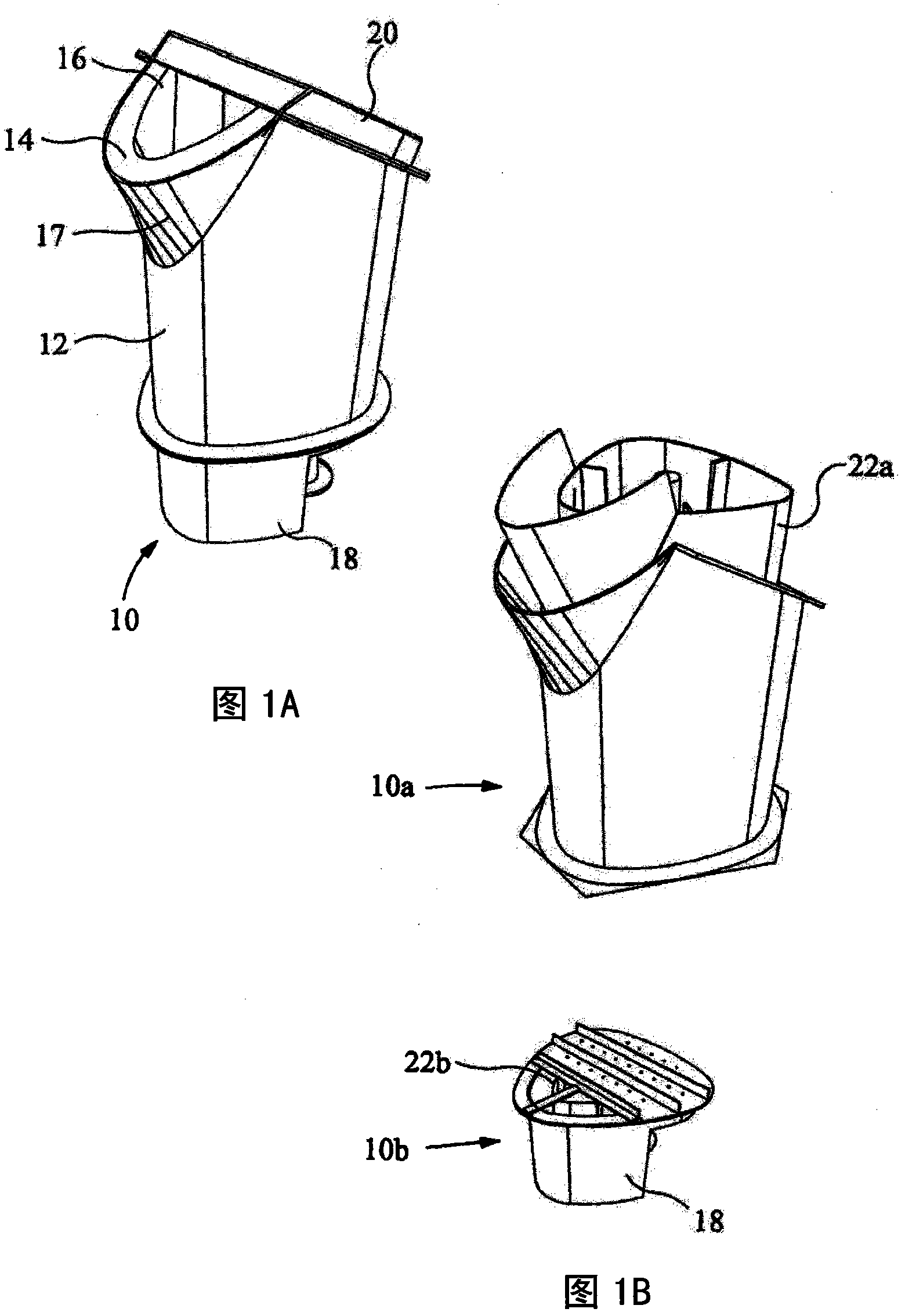

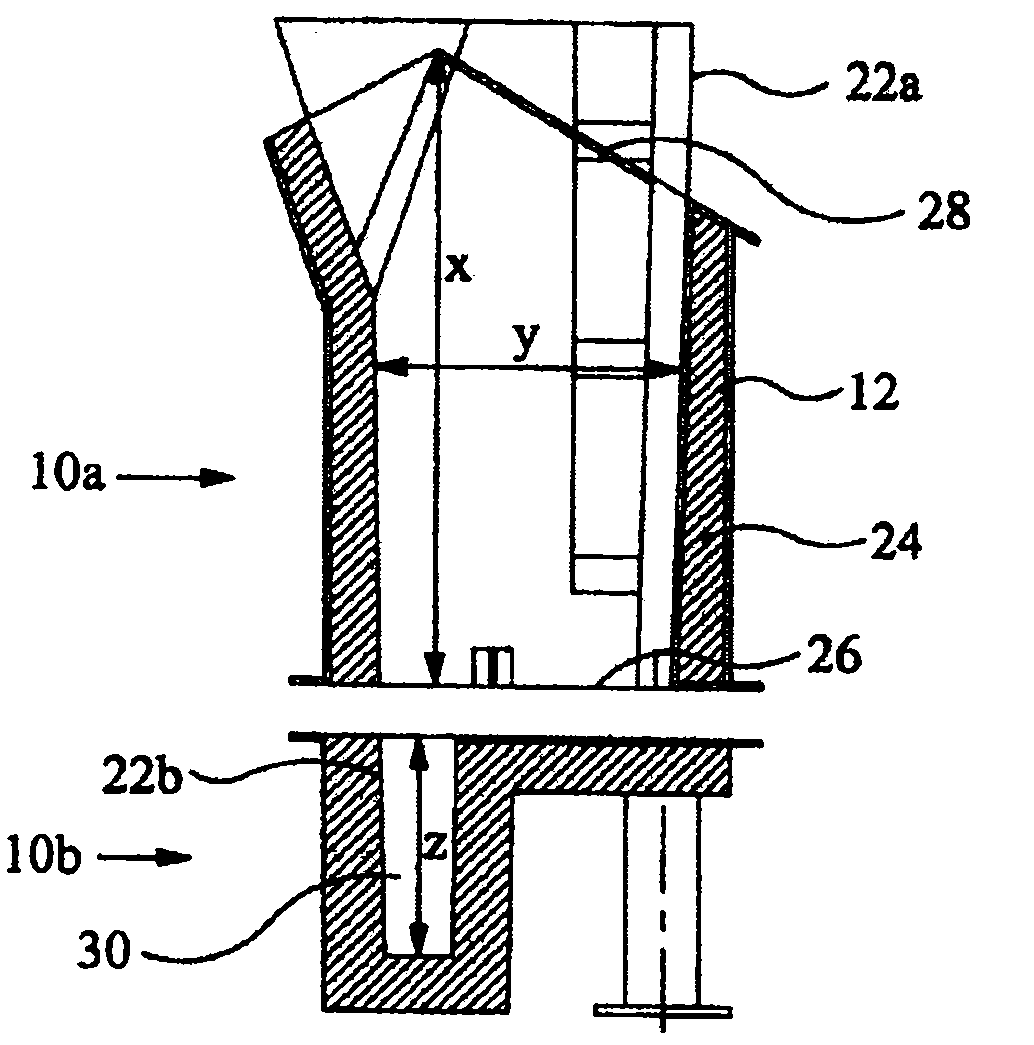

[0079] show on Figure 1A The steel ladle 10 in is placed in a vertical position, and the material bag is at the lowest point. 20.8 kg of magnesium ferrosilicon (5.38% Mg) was then loaded into the pocket using a long necked funnel placed in the opening. After loading the treatment agent, the ladle is rotated 90° to the horizontal position. Subsequently, the ladle is filled with 1600 kg of molten iron at a temperature of 1480°C. The ladle then pivots back to the vertical position, allowing the molten iron to flow into the pocket. White flames are seen when molten iron reacts with magnesium alloys. The metal is poured out of the spout 17 by tilting the ladle. The result is as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com