High precision grinding machine

A high-precision, grinding machine technology, used in grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of unstable center of gravity of machine tools, affecting workpiece machining accuracy, vibration, etc., to achieve improved machining accuracy and stable structure. Reliable, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

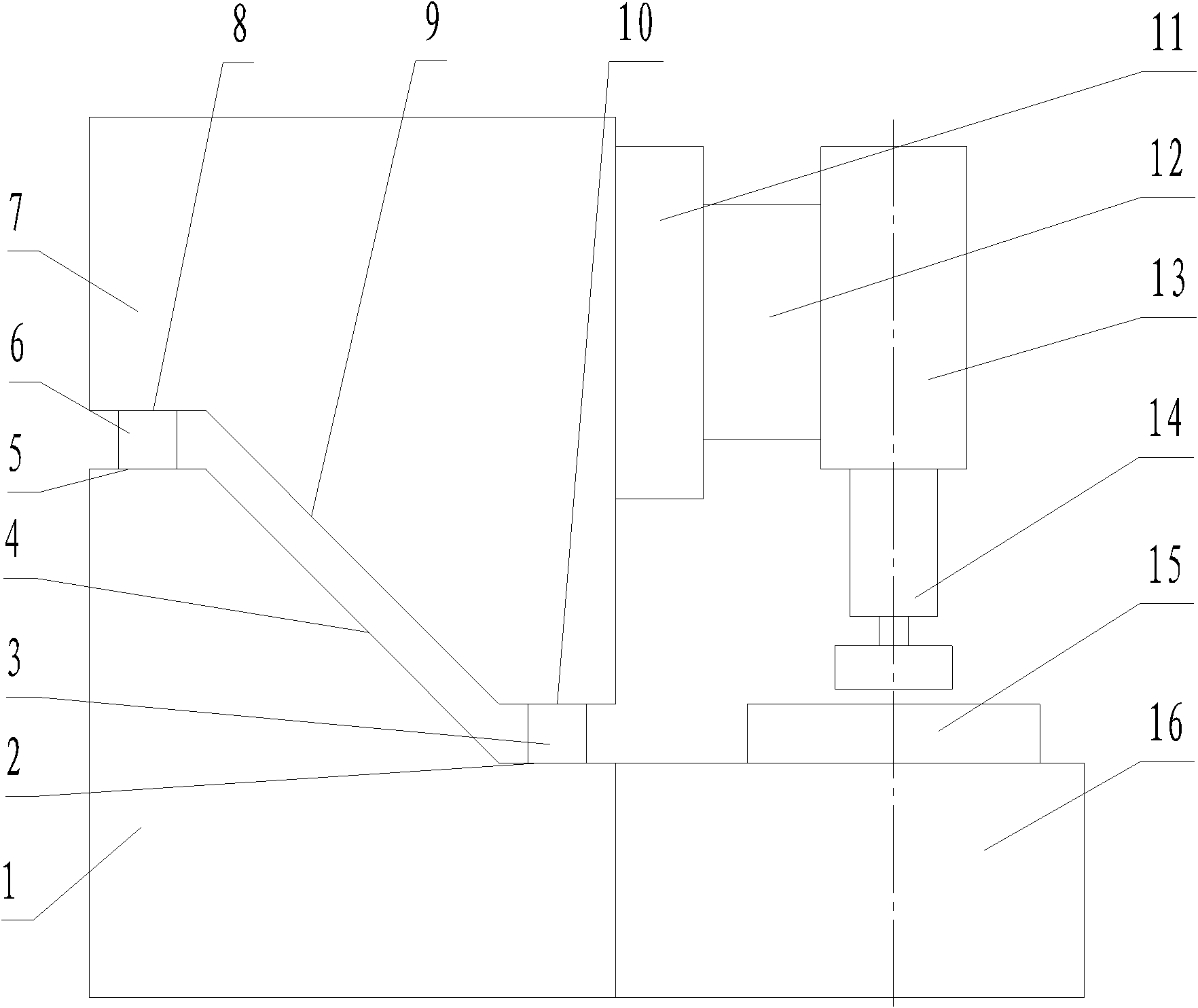

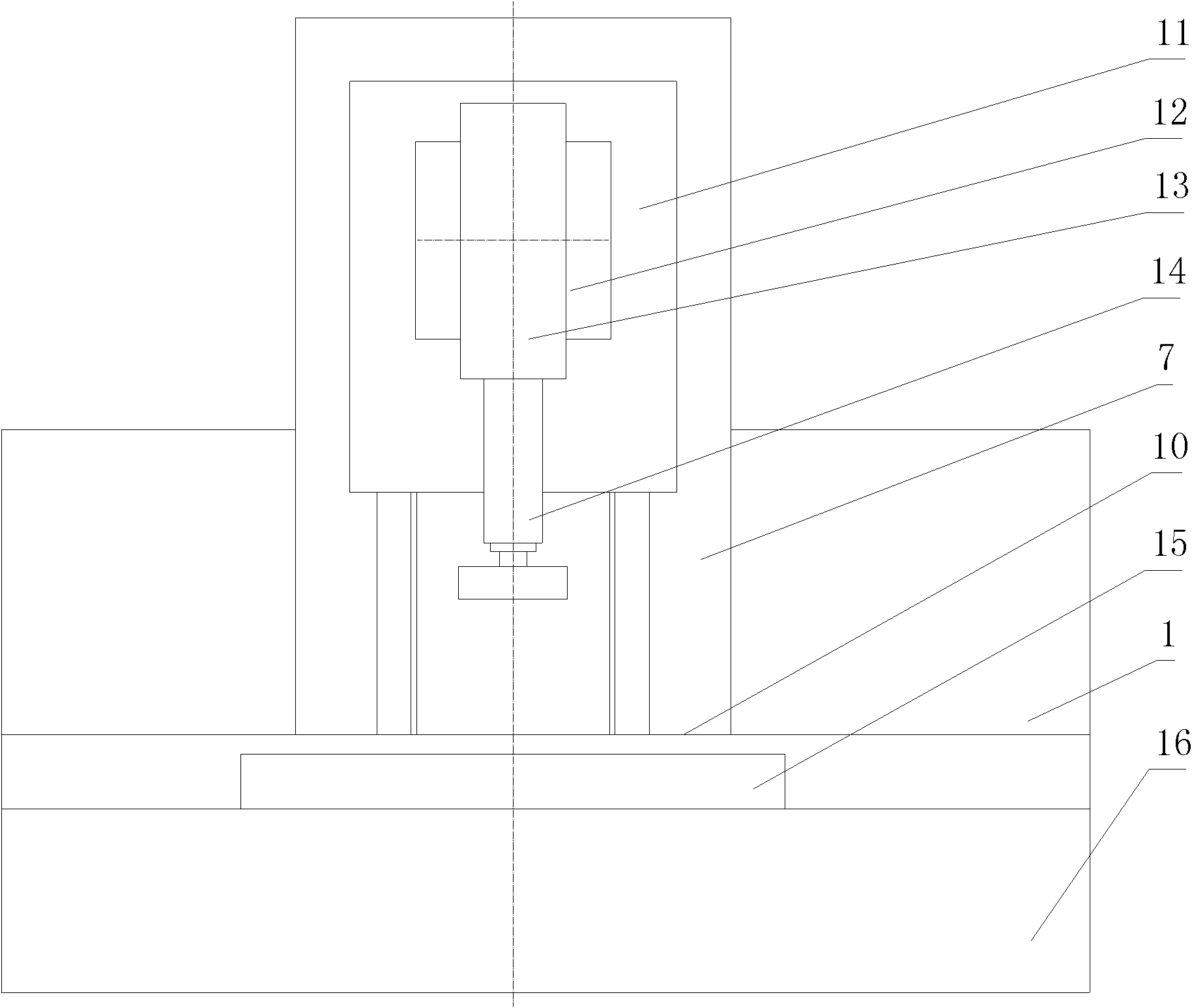

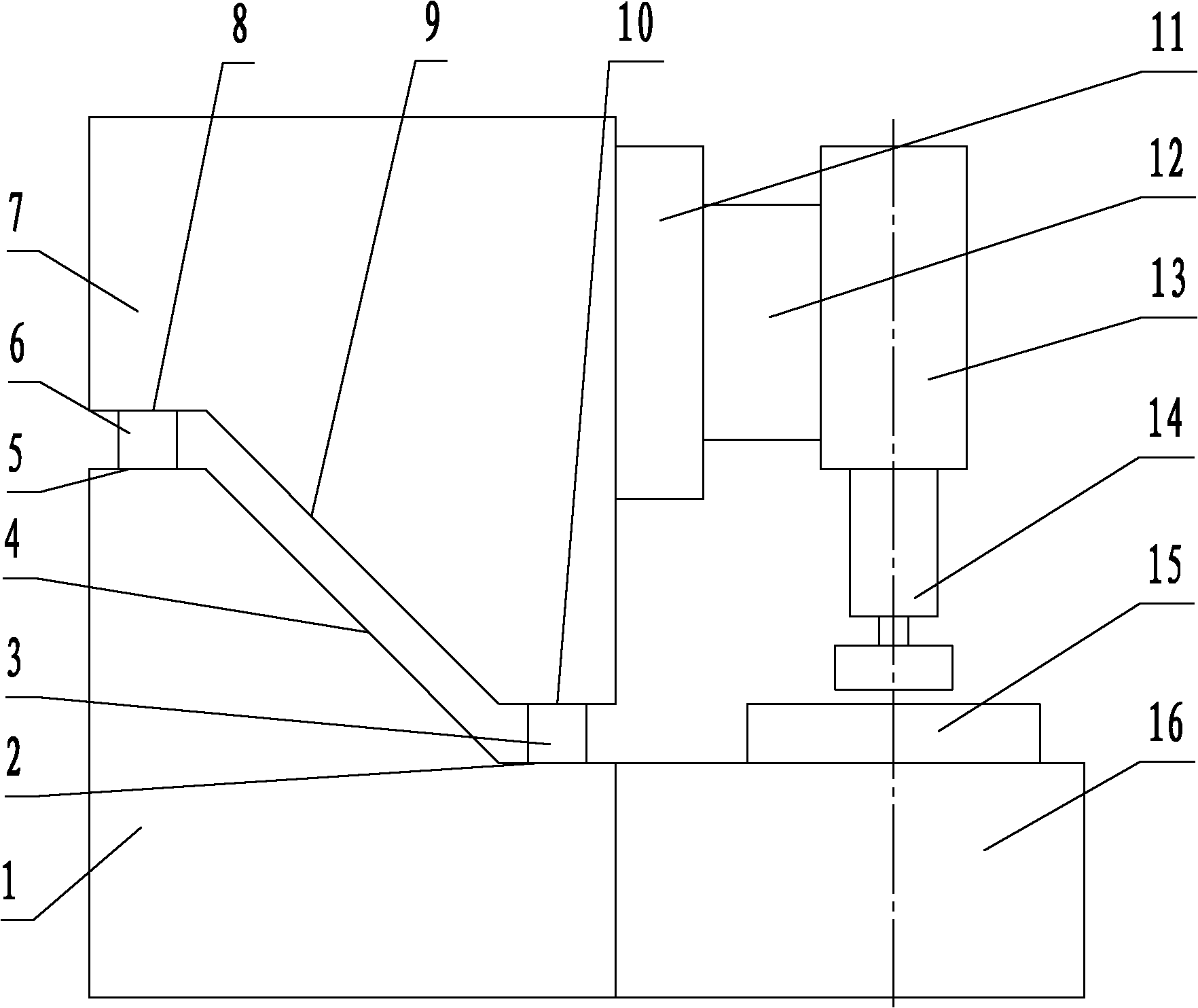

[0012] See figure 1 , figure 2 , The bed consists of a front bed 16 and a rear bed 1, and the rotary table 15 is installed on the front bed. There is a 45° inclined plane 4 on the upper surface of the rear bed, narrow and long platforms 2 and 5 are formed on the front and rear sides of the inclined plane, and a movable column 7 is movably installed on the slope of the rear bed, and the bottom surface of the mobile column corresponds to a 45° The inclined plane 9 and the narrow and long platforms 8, 10, the narrow and long platforms of the rear bed are installed with guide rails 3 and 6 for moving the column, the moving column is installed with a carriage 11, and the indexing mechanism 12 is installed on the carriage, and the dividing The main shaft 13 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap