Drilling machine tool special for opencast mining rotary drill rig and using method thereof

An open-pit mining and roller cone drilling rig technology, applied in the field of mining machinery and equipment, can solve the problems of inaccurate hole depth, insufficient hole depth, and low porosity, and achieve accurate depth control, good slag blocking effect, and improved porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention are described below in conjunction with the drawings.

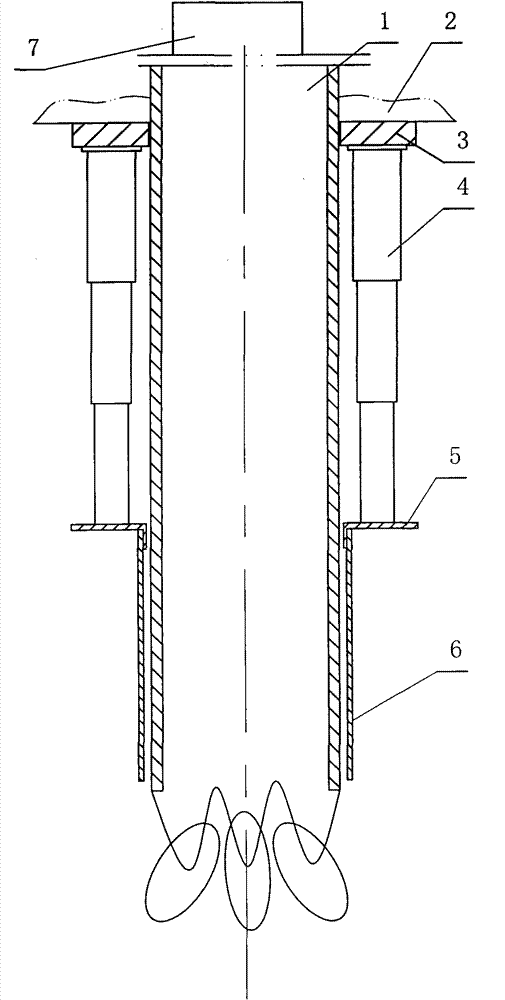

[0021] Such as figure 1 As shown, the open-pit mining roller cone drilling special machine tool of the present invention includes a drill rod 1, a fixed seat 2 rotatably connected with the drill rod, a roller drill air compressor, a pneumatic control device 7 and a slag stopper 6, which It is characterized in that a base 3 is provided on the fixed seat 2, and a group of pneumatic jacks 4 connected to the air compressor of the roller drill is evenly arranged in the circumferential direction of the base 3. The front end of the rod is connected with a gland 5 to form a base-pneumatic jack-gland assembly. The gland 5 is connected with the end of the slag stopper 6.

[0022] The base 3 is a ring-shaped flat base, and the center hole of the base matches the outer diameter of the drill rod 1.

[0023] The set of pneumatic jacks 4 is 3-5 pneumatic jacks.

[0024] A method for usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com