Friction-type roller overrunning clutch

An overrunning clutch and roller technology, applied in friction clutches, clutches, one-way clutches, etc., can solve the problems of more blank materials, low yield, long working hours, etc., to reduce processing volume, reduce materials, and improve The effect of processing ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

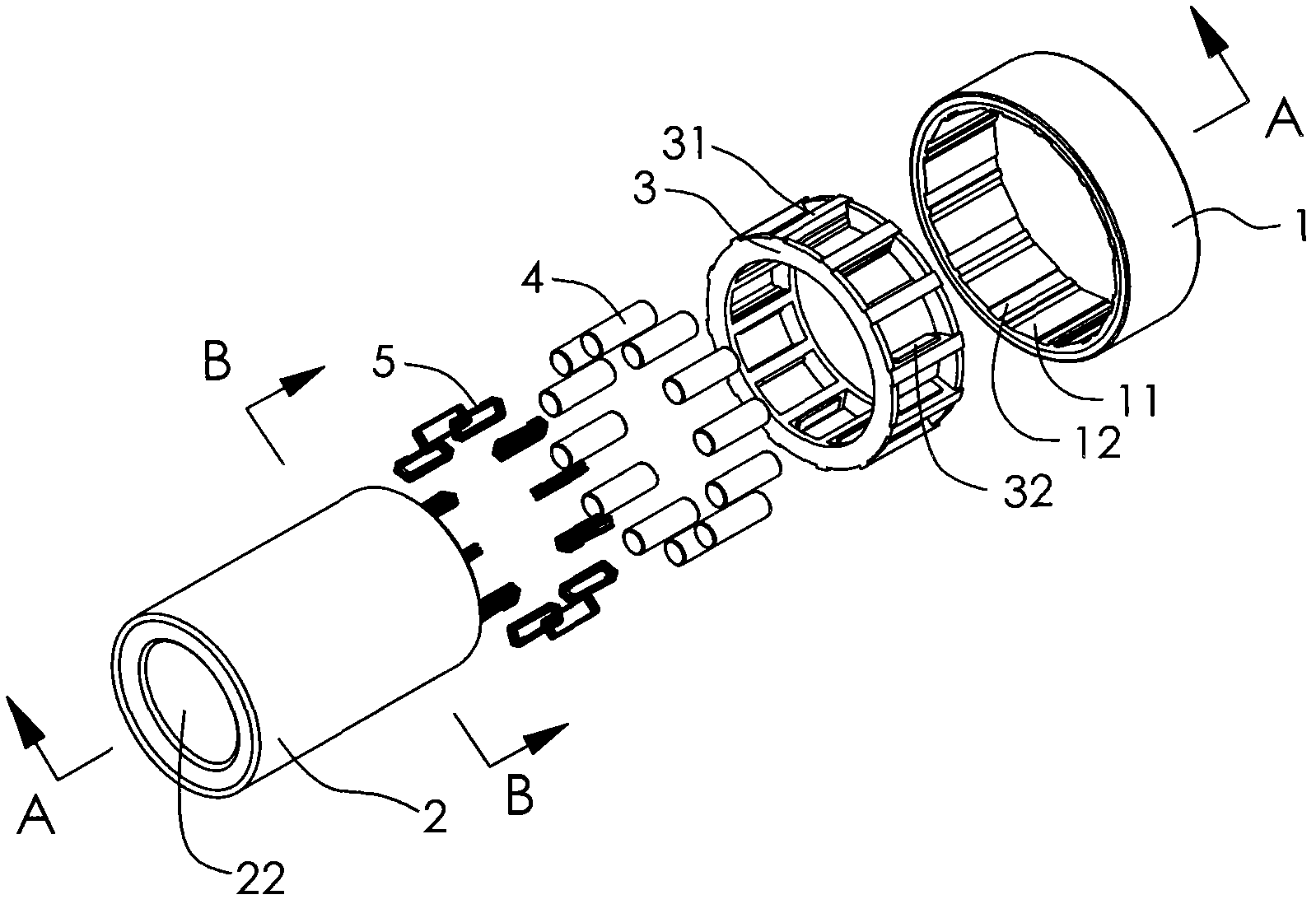

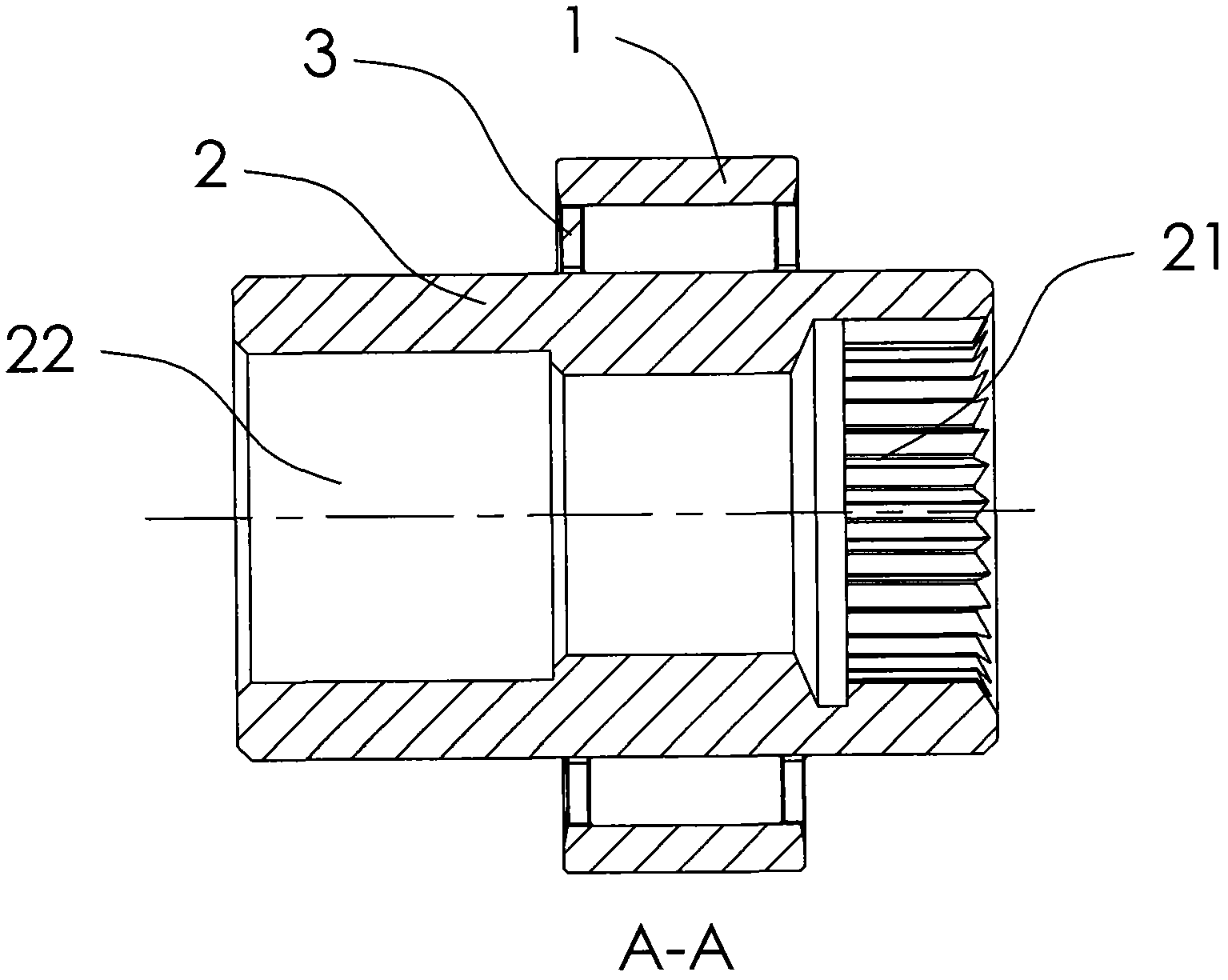

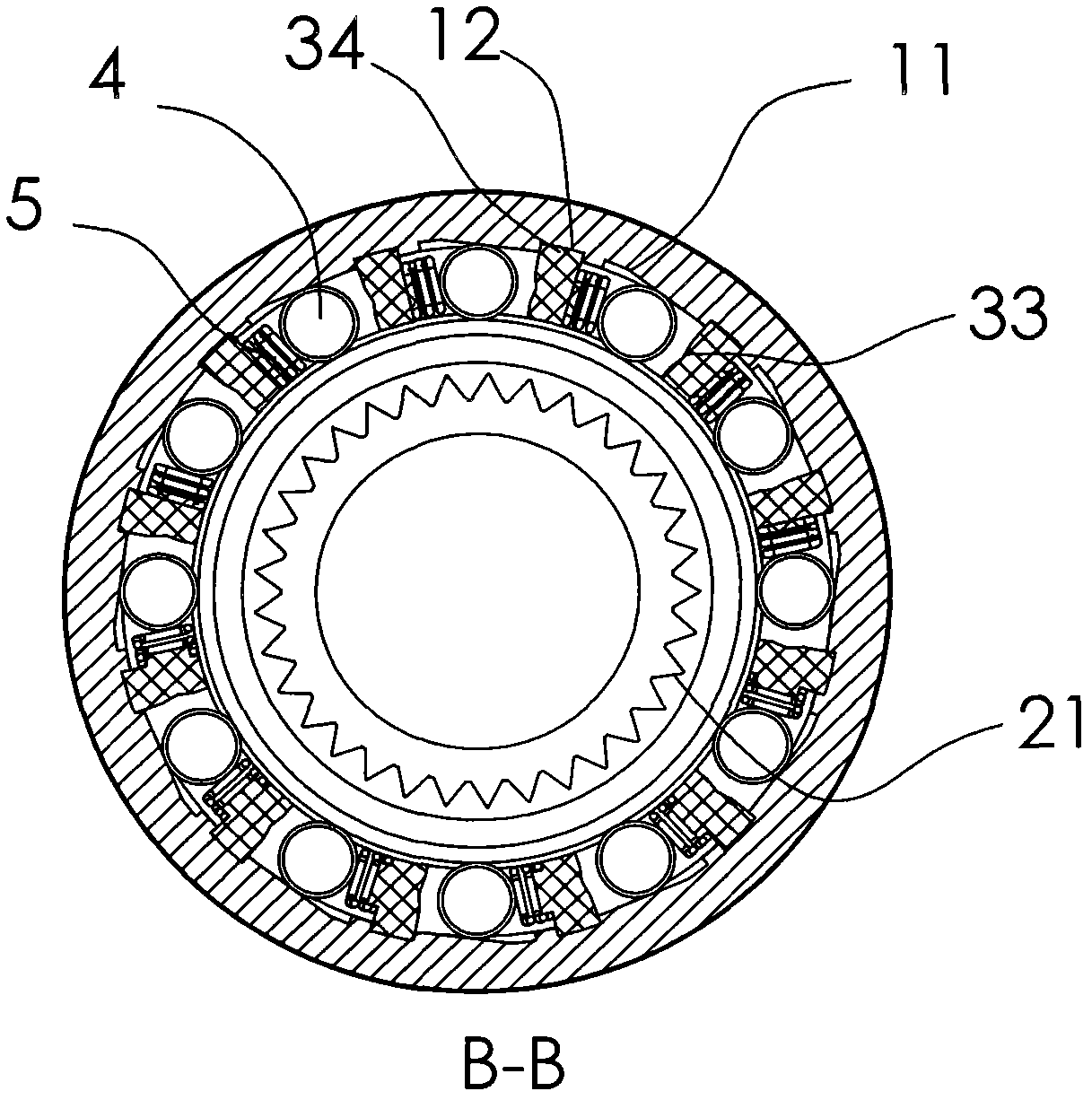

[0020] Overrunning clutch of the present invention such as Figure 1-3 As shown, it includes a cylindrical inner ring 2, an annular outer ring 1, a roller 4, a cage 3 and a return spring 5, the outer ring 1 and the inner ring 2 are coaxially fitted, and the cage 3 is set inside, Between the outer rings, the cage 3 is a squirrel-cage cylindrical structure, and the circular frames at both ends are equidistant and axially provided with connecting strips 31. The connecting strips 31 are rectangular columnar structures, and the connecting strips 31 connect the cage The outer surface is divided into uniform grids, and rollers 4 with matching dimensions and axial direction consistent with the outer ring are embedded in the grids....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com