Preparation method of shallow trench isolation structure

A technology of isolation structure and shallow trench, which is applied in the field of preparation of shallow trench isolation structure, and can solve problems such as smearing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

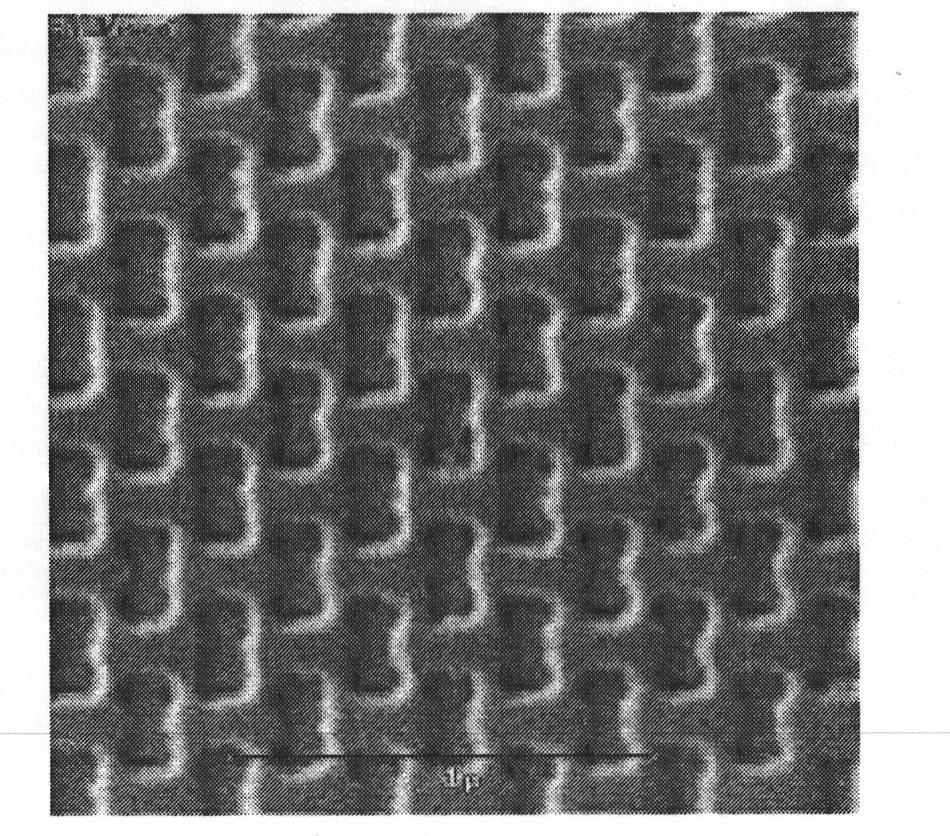

[0014] The preparation method of the shallow trench isolation structure includes the following steps: S10, depositing a silicon dioxide pad layer on the silicon substrate; S20, depositing a silicon nitride layer on the pad layer to protect the active region; S30, Engraving and defining the STI trench area; S40, etching the oxide layer and nitride layer, and removing the photoresist; S50, dry etching the STI trench; S60, filling the STI trench with a high-density plasma chemical vapor deposition oxide layer, Before filling, a layer of silicon dioxide can be formed on the surface of the trench by thermal oxidation; S70, chemical mechanical grinding and removal of the nitride layer.

[0015] After many experiments and analysis, we believe that the cause of smear defects in the traditional shallow trench isolation process is that there is a significant difference in the height of the oxide layer on the nitride layer at the junction of the shallow trench isolation dense area and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com