Solenoid arrangement and valve arrangement

A technology of magnet device and valve device, which is applied in the direction of electromagnets, magnets, electromagnets with armatures, etc., to achieve the effect of good closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

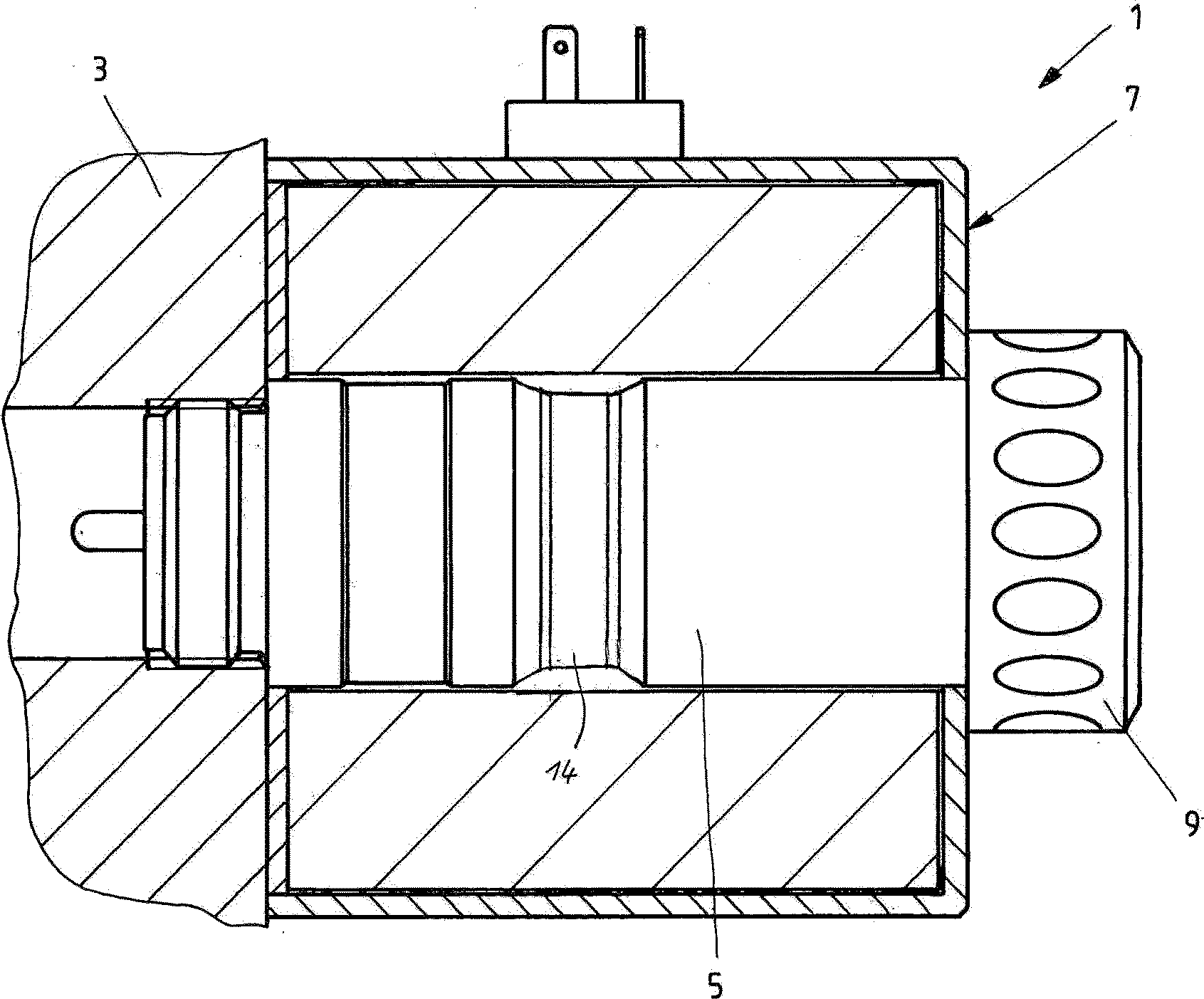

[0023] figure 1 A typical arrangement of a stroke magnet 1 is shown, as it is used for actuating fluidic switching valves. The pole tube 5 of the stroke magnet 1 is screwed into the valve bore on the valve housing 3 . An excitation coil 7 is set on the pole tube 5 . The field coil 7 is fastened to the pole tube 5 by means of nuts 9 . The pole tube 5 is constricted with respect to its outer diameter in the transition section 14 .

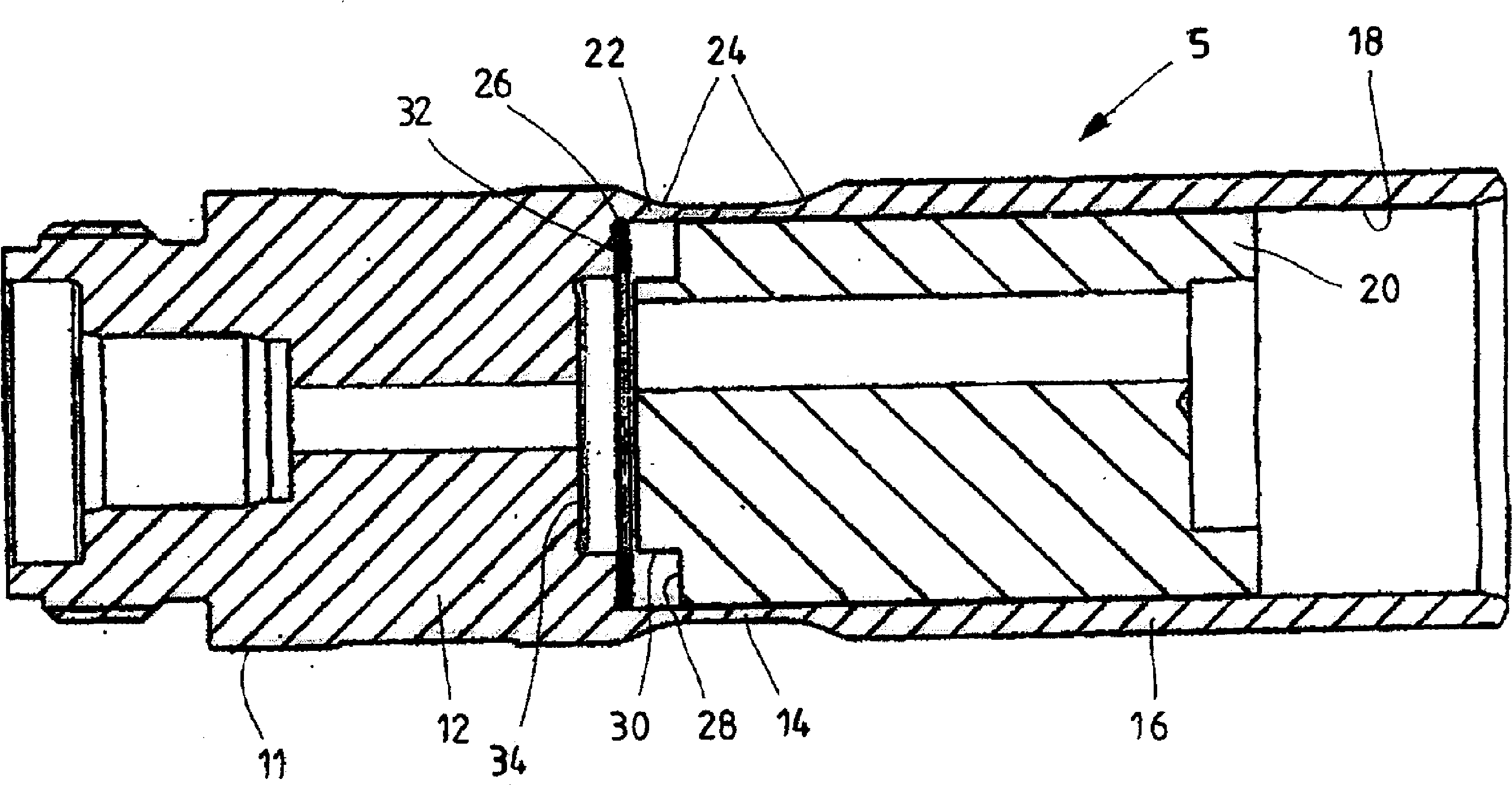

[0024] figure 2 The arrangement of the pole tube 5 according to the invention and of the armature guided in it is described. The pole tube body 11 is prepared from ferromagnetic steel, for example from a rod, by machining into the shape shown.

[0025] The pole tube body 11 is axially divided into a pole core 12 , a transition section 14 and a tube section 16 . The overall sleeve-like shape of the pole tube body 11 allows the armature 20 to be inserted into the central bore 18 . At its end facing away from the pole section 12 after the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com