Upside step type poultry carcass precooler set

A step-type, pre-cooler technology, applied in the direction of coolers, carcass cooling, cold storage, etc., can solve the problems of not too small drop, overall height increase, waste of electric energy, etc., to reduce the degree of pollution and reduce operating costs , The effect of saving cold source energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

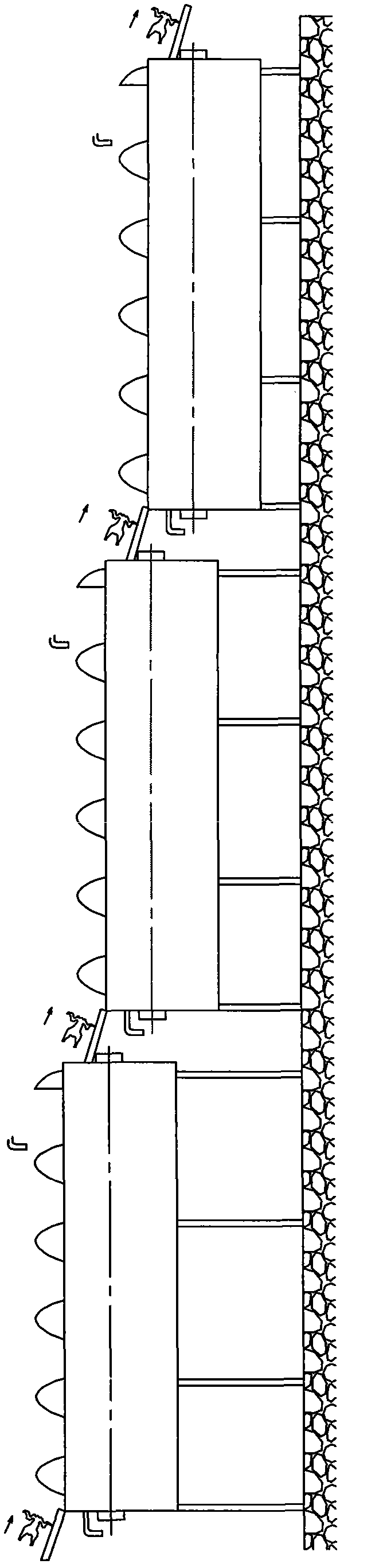

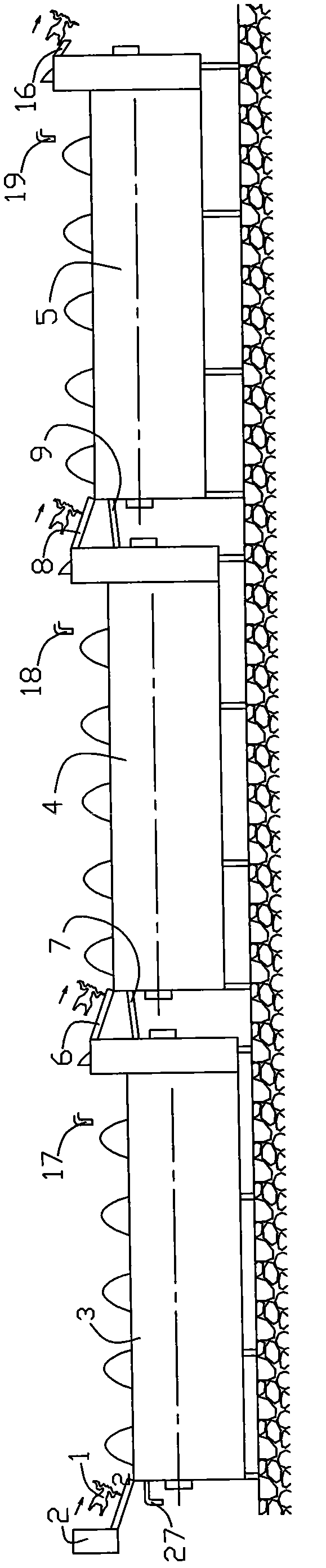

[0025] The pre-cooling unit is composed of multiple single pre-cooling machines arranged in series, and the number of pre-cooling machines can be determined according to the needs. like figure 2 Shown is a three-unit unit: the poultry carcass 1 is unloaded from the equipment 2 of the previous process, and passes through the spiral precooler 3, the precooler 4 and the precooler 5 in turn. These three pre-coolers are arranged in the form of upper steps. That is to say, the first pre-cooler 3, the second pre-cooler 4, and the third pre-cooler 5 rise successively. A chute 6, a water tank 7, a chute 8 and a water tank 9 are connected between the precoolers.

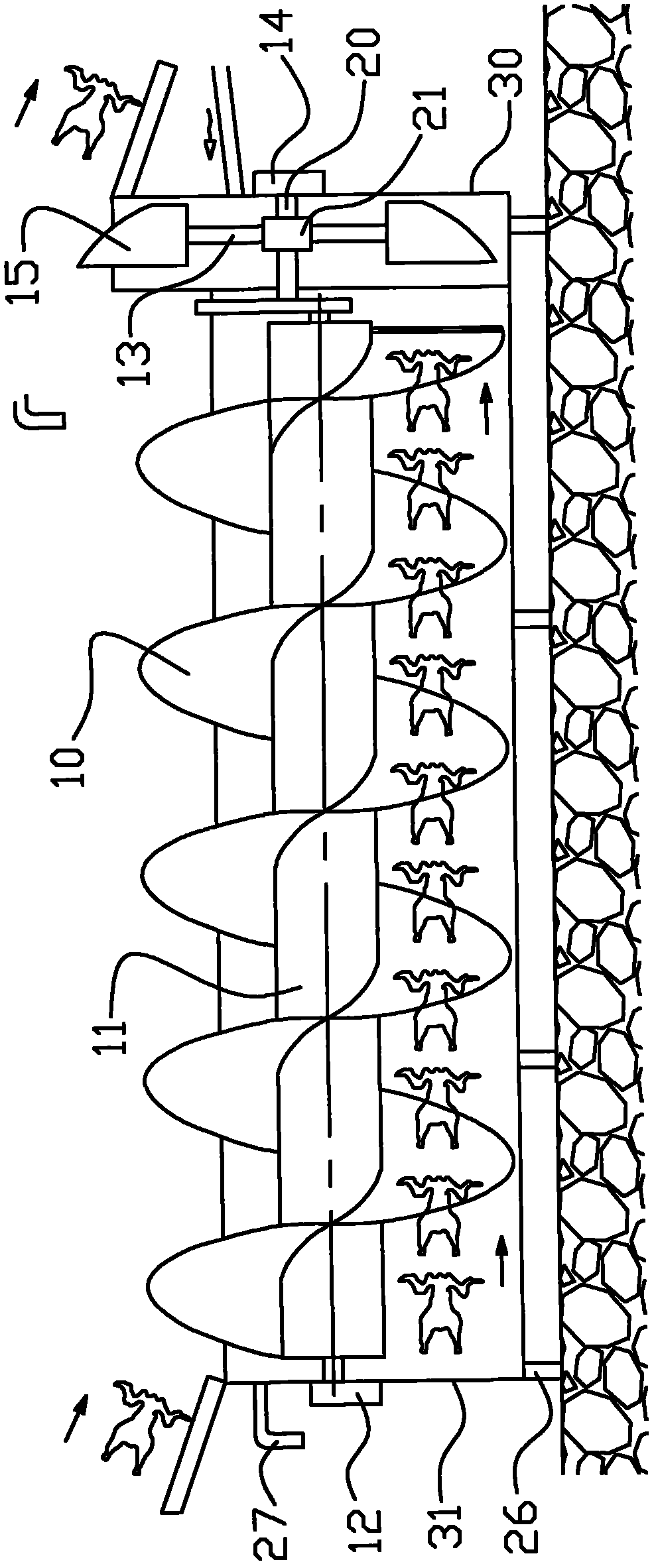

[0026] like image 3 As shown, each precooler is provided with a screw propeller composed of blades 10 and a shaft 11, and the shaft 11 is driven to rotate by a driving device 12. The poultry carcass outlet end is provided with the poultry carcass of high outlet and turns over the mechanism, turns over the mechanism by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com