Preparation method of functionalized fly ash and zeolite composite particles

A technology of composite particles and fly ash, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of unsuitable ammonia nitrogen and phosphate removal, low ion adsorption capacity, nitrogen and phosphorus The problem of strong single release is solved, and the effect of simple operation, wide application and simple equipment is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

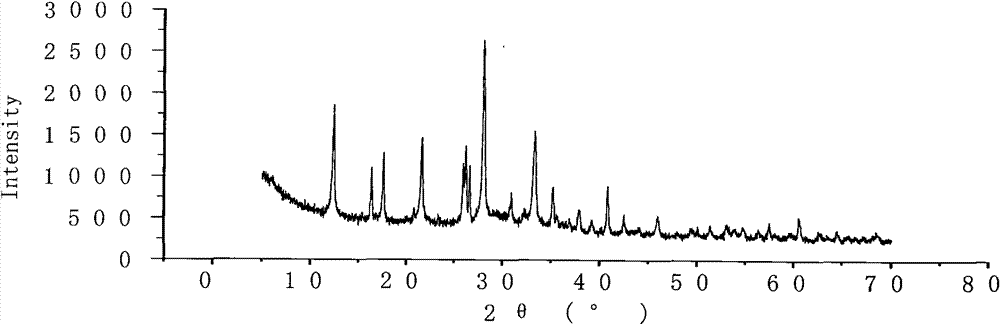

[0033] Take 20g and pulverize it into 60 mesh sample 1 fly ash (the composition of Si\Al is 1.93:1), bake it at 90°C for 12h, then add 0.96g of sodium hydroxide and 40g of water and mix evenly (according to the mass ratio, the fly ash : alkali metal: water=100: 4.8: 200), at a temperature of 60 ° C, a stirring speed of 100 rpm under the conditions of the reaction 5h; add sodium aluminate to make the total content of silicon and aluminum in the preliminary hydrothermal physical and chemical reaction product The molar ratio is 1.5:1, continue to react for 20h; dope calcium oxide 0.2g (according to mass ratio, fly ash: calcium oxide=100:1), continue to react for 2h. The reaction product is filtered to obtain sediment, and the sediment is washed with deionized water to reduce the pH of the sediment to 8-10. Dry at 85°C for 24 hours to obtain fly ash nano-zeolite composite particles. The XRD diffraction analysis of its mineral composition is shown in 1. The synthesized product has ...

Embodiment 2

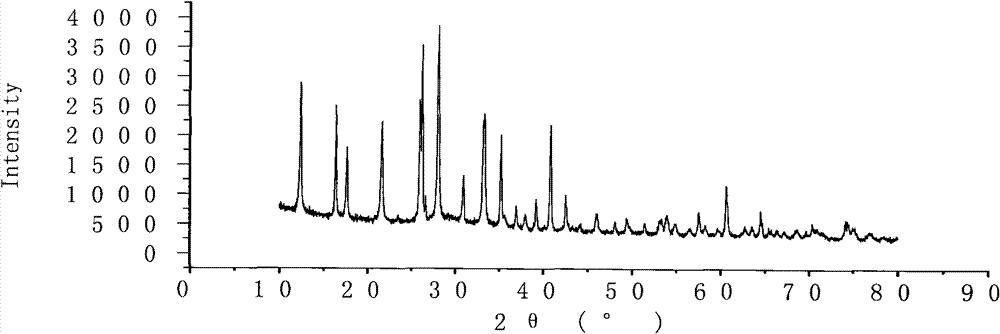

[0035] Take 20g and pulverize it into 60 mesh sample 1 fly ash (the composition of Si\Al is 1.93:1), bake it at 90°C for 12h, then add 1.92g of potassium hydroxide and 40g of water and mix evenly (according to the mass ratio, the fly ash : Alkali metal: water=100: 9.6: 200), at a temperature of 120 ° C, a stirring speed of 100 rpm under the conditions of the reaction 15h; adding alumina to make the preliminary hydrothermal physical and chemical reaction product of the total content of silicon and aluminum The molar ratio is 1:1, and the reaction is continued for 85 hours; doped with 1 g of calcium hydroxide (according to the mass ratio, fly ash: calcium hydroxide=100:5), and the reaction is continued for 5 hours. The reaction product is filtered to obtain sediment, and the sediment is washed with deionized water to reduce the pH of the sediment to 8-10. Dry at 85° C. for 24 hours to obtain fly ash nano zeolite composite particles. As shown in Table 1, the cation exchange capa...

Embodiment 3

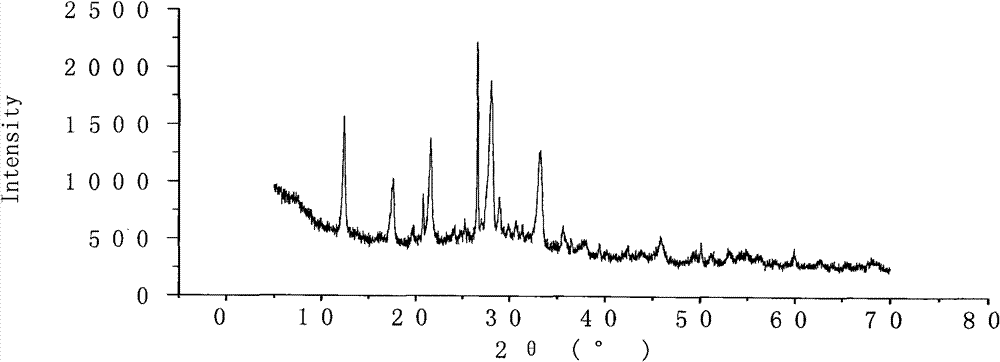

[0037] Take 20g and pulverize it into 60 mesh sample 1 fly ash (composition Si\Al is 1.93:1), bake at 90°C for 12h, then add 0.96g of sodium bicarbonate and 240g of water and mix evenly (according to mass ratio, fly ash : alkali metal: water=100: 4.8: 1200), at a temperature of 80 ° C, a stirring speed of 100 rpm under the conditions of the reaction 8h; adding aluminum hydroxide to make the preliminary hydrothermal physical and chemical reaction product of the total content of silicon and aluminum The molar ratio of the mixture was 1.2:1, and the reaction was continued for 48 hours; doped with 0.5 g of calcium chloride (according to the mass ratio, fly ash: calcium chloride=100:2.5), and the reaction was continued for 3 hours. The reaction product is filtered to obtain sediment, and the sediment is washed with deionized water to reduce the pH of the sediment to 8-10. Dry at 85° C. for 24 hours to obtain fly ash nano zeolite composite particles. As shown in Table 1, the cation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com