Auxiliary fixture for making test support for high-density interconnection circuit board

A technology of high-density interconnection and auxiliary fixtures, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

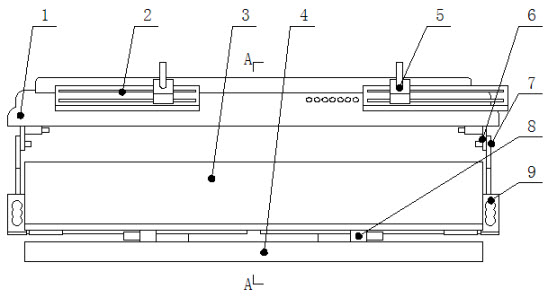

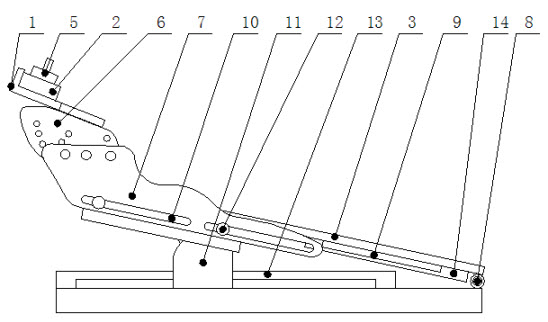

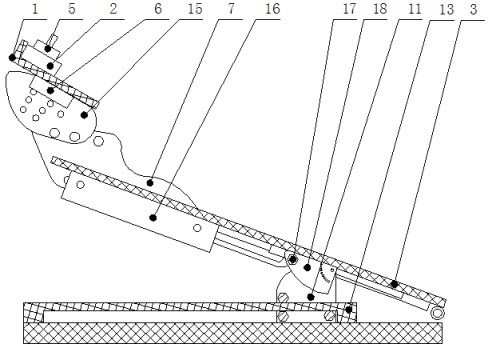

[0021] A high-density interconnection circuit board test bottom bracket making auxiliary fixture, such as Figure 1-7 As shown, the innovation of the present invention is: comprise base 4, movable plate 3, side plate 7, upper plate 1, supporting device and binding horn 2, movable plate is hinged on the front side of base by lotus leaf plate 8, in movable Two side plates are symmetrically installed on both sides of the plate by limiting sliding. The upper ends of the two side plates are fixed on the bottom surface of the upper plate. A binding horn is installed on both ends of the upper plate by limit sliding, and a A supporting device for jacking up a movable panel.

[0022] The limit sliding structure of the side plate is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com