Potential energy storage type protruding undercarriage buffer

A landing gear buffer and protrusion technology, which is applied in the direction of shock absorbers, shock absorbers, gas-hydraulic shock absorbers, etc., can solve the problem that dust easily pollutes the working environment of the landing gear, the working reliability cannot be guaranteed, and the weight of the landing gear increases and other problems, to achieve the effects of obvious protrusion effect, short protrusion time and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

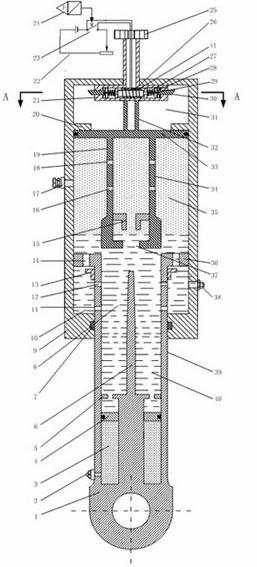

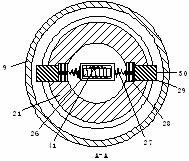

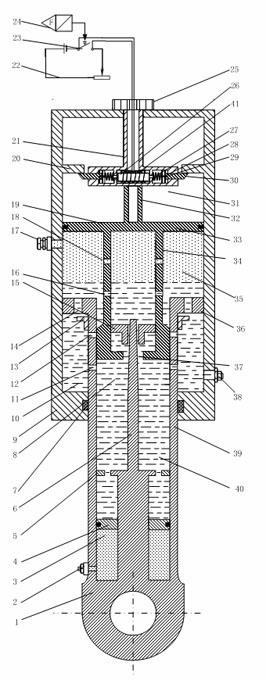

[0011] As attached figure 1 Shown is a schematic diagram of the structure of the potential energy storage type protruding landing gear bumper bar before it is compressed downwards. The piston rod 1 is sleeved in the outer cylinder 9 from the bottom of the outer cylinder 9, moves axially relative to the outer cylinder 9 and is sealed with it; the piston rod 1 is fixed to the upper end of the piston rod outer cylinder by a variable section oil needle 6, a piston rod outer cylinder 39 and The outer wall of the piston rod 39 is formed with an upper oil hole 12 and a lower oil hole 11, the annular piston 36 is provided with an oil return hole 14, and the outer wall of the piston rod 39 has an upper oil hole 12 There is also an oil return hole throttle valve 13 installed on the upper side; the inner lower end of the piston rod outer cylinder 39 is also installed with a high-pressure chamber floating piston 4 and a retaining ring 5 that limits the highest position of the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com