Water filling valves with four-direction-operation arc doors

A water filling valve and arc door technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., and can solve problems such as valve core jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

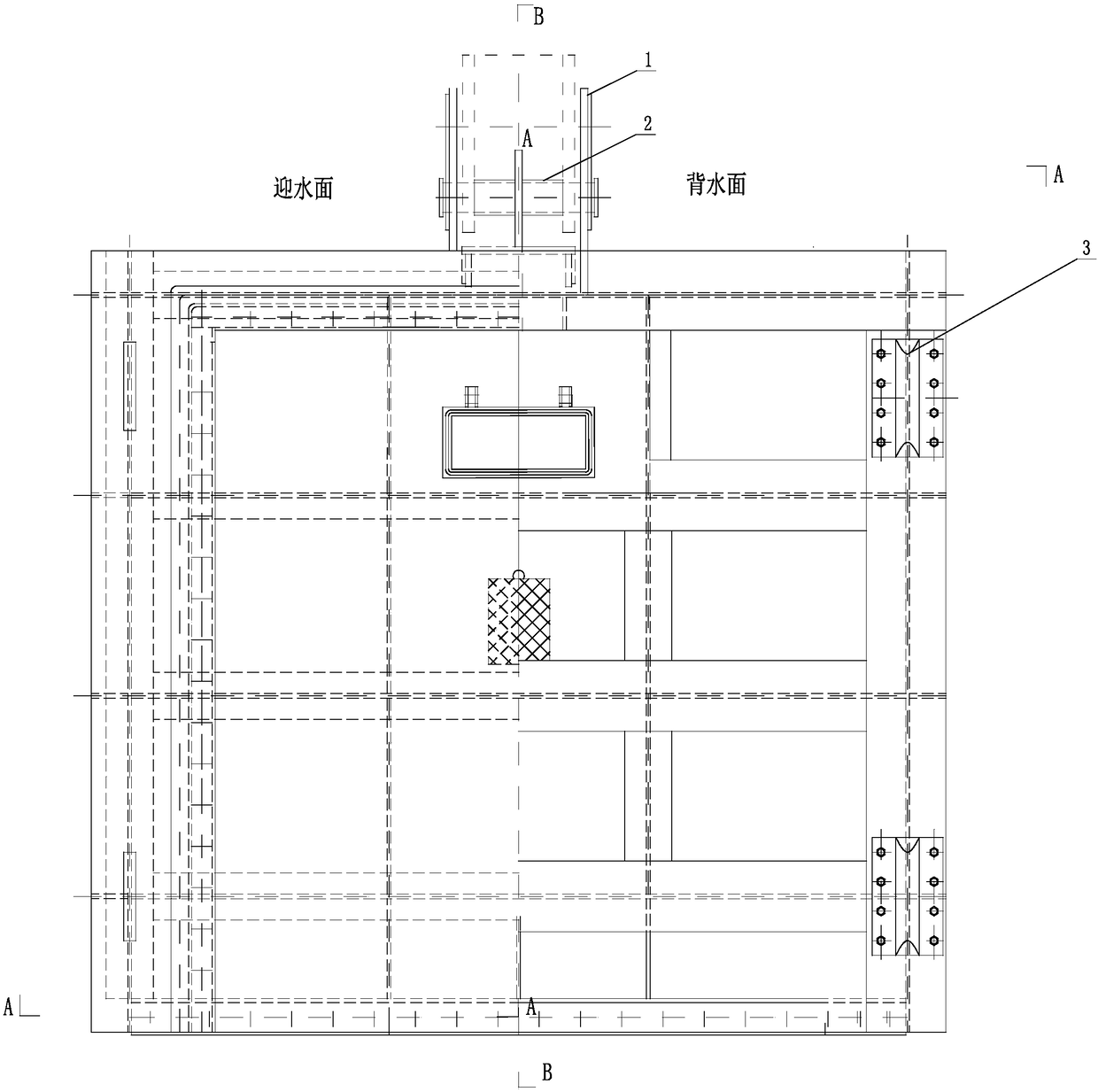

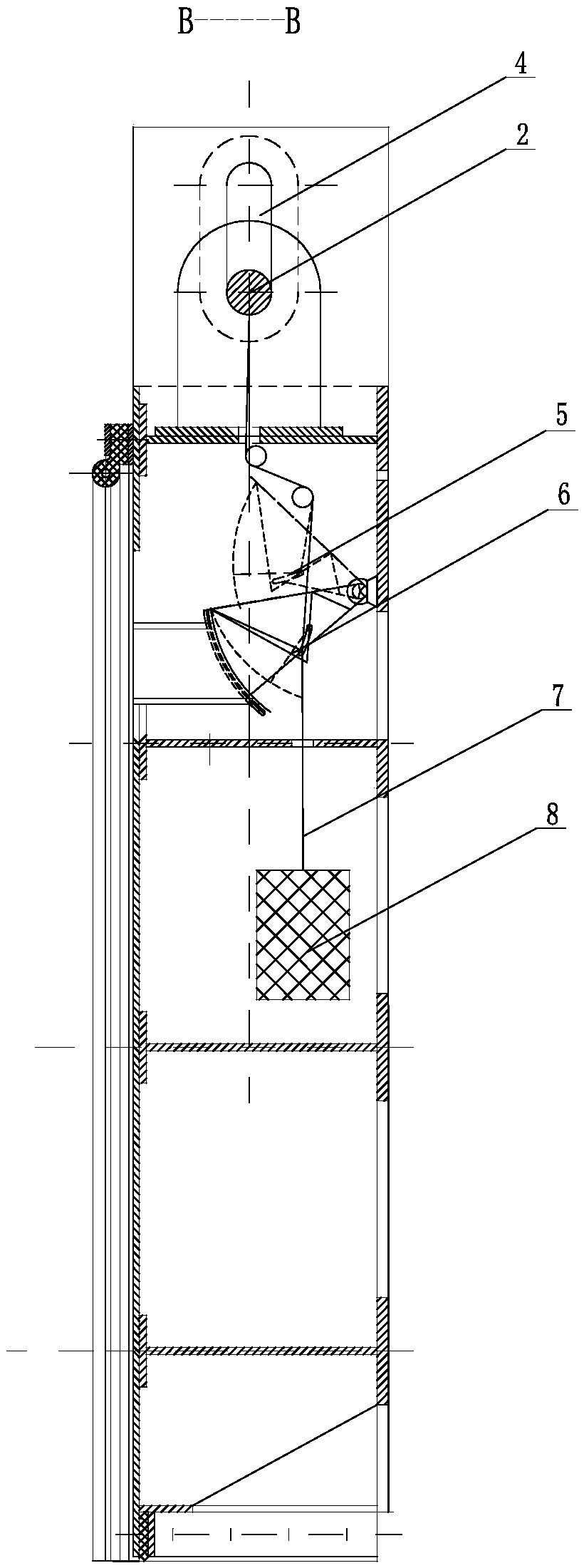

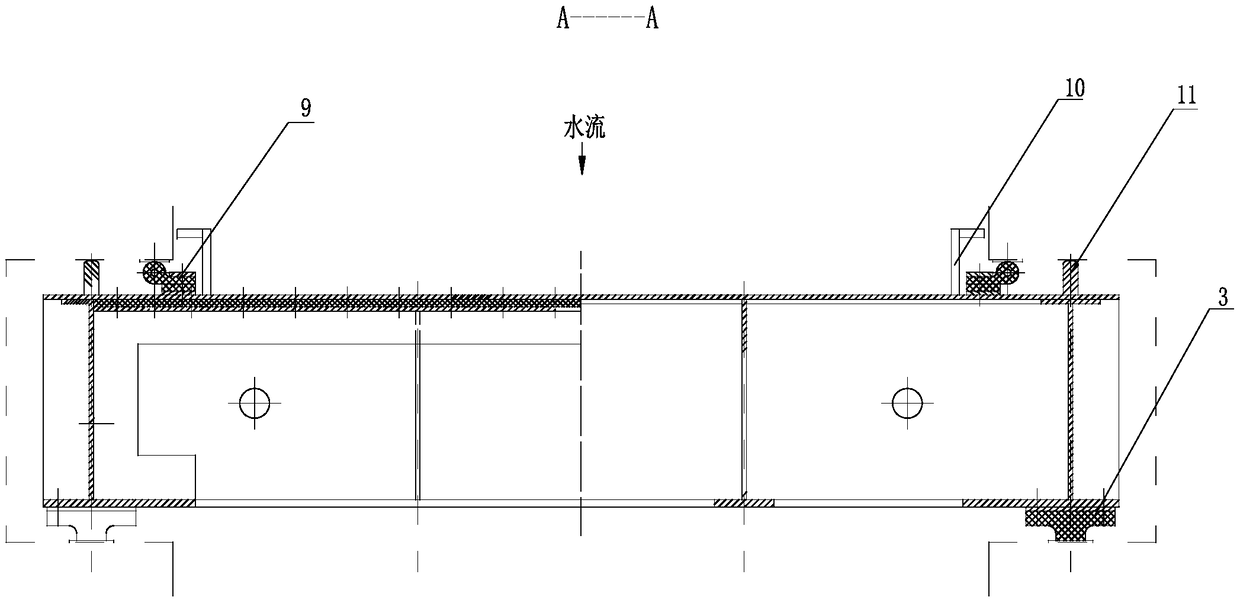

[0027] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1-10As shown, the four-way running arc gate water filling valve is installed in the top beam grid of the gate, and each gate is provided with a water filling valve directly below the hanging shaft 2, and the water filling valve and the center of the hanging shaft are in a vertical plane The water filling valve includes a water filling pipe 21, a water seal base 19, a mountain-shaped water seal 20, a water seal pressure plate 26, a four-way running arc door, a fixed pulley 12, a stay rope 13, a pull rod 7 and a counterweight 8, and a water filling pipe 21 The cross section is rectangular, the front end of the water-filling pipe is welded to the gate panel, and the rear end is welded to the water seal base 19. The mountain-shaped water seal 20 is installed in the groove of the water seal base, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com