Flap type gas motor valve

A motor-valve, flap-type technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of large electric power, affecting the normal use and management of gas, long opening time and closing time, etc.

Active Publication Date: 2011-06-15

广州金燃智能系统有限公司

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The embodiment of gas transmission and distribution capacity is mainly the stability or guarantee of gas transmission pressure, which can ensure that gas users at the end of the pipeline can also effectively use gas. Therefore, in the transportation of gas pipelines along the way, the pressure of gas transmission should be minimized loss, and various gas cut-off valves (including various types of gas motor valves) in the pipeline are important factors that will reduce the gas transmission pressure, that is to say, the gas flow in the pipeline During the transportation process, there will be a large pressure loss when passing through the valve. Therefore, how to reduce the pressure loss caused by the gas cut-off valve is a matter of great concern in the industry. Although the pressure loss of the ball valve is small and the use is very common, but It is still not ideal, especially the gas cut-off valves used in gas pipelines with larger diameters (such as DN50 ~ DN150 caliber)

In addition, the opening and closing time of the gas motor valve used for gas cut-off is relatively long, and the power consumption is also large, which often affects the normal use and management of gas.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

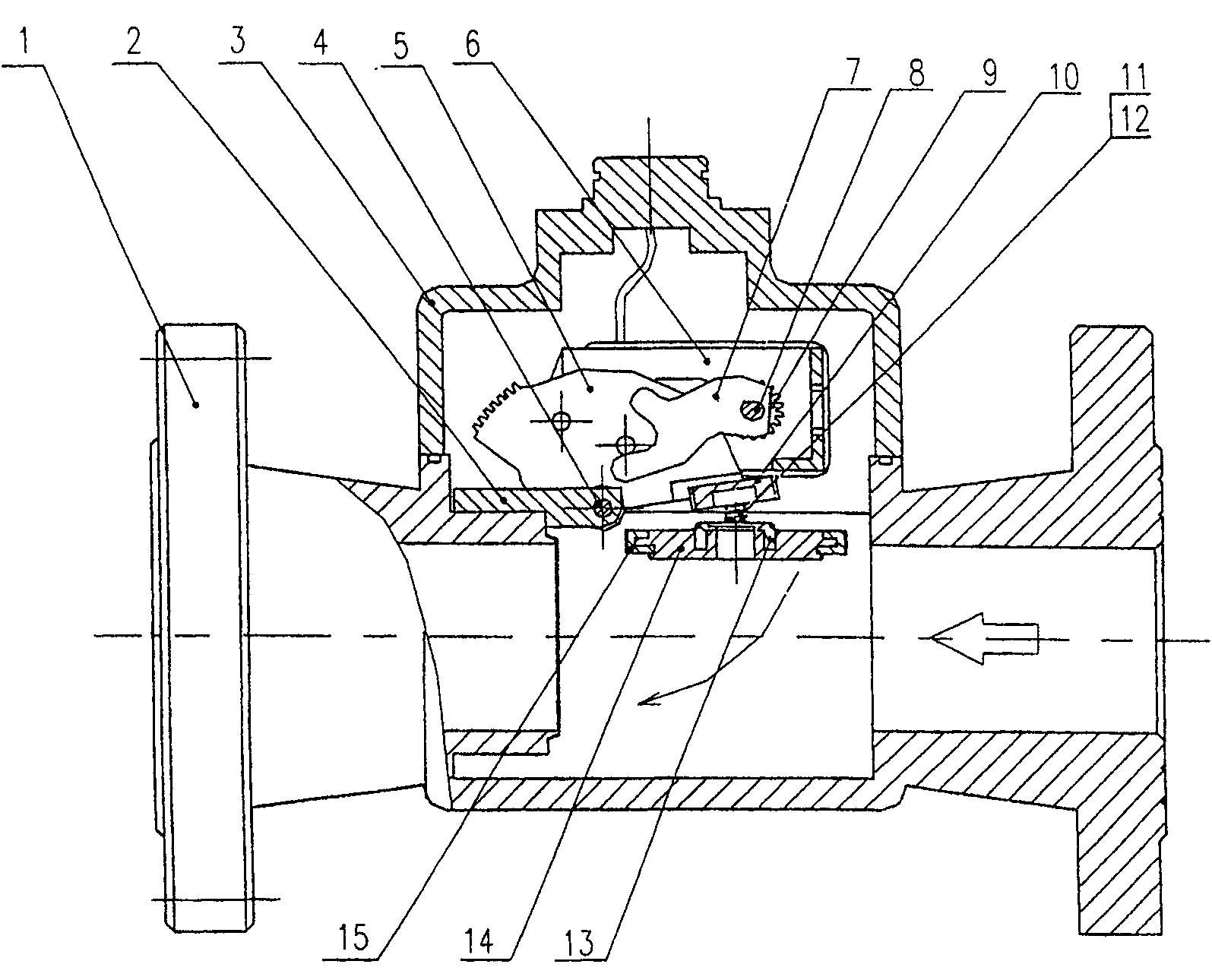

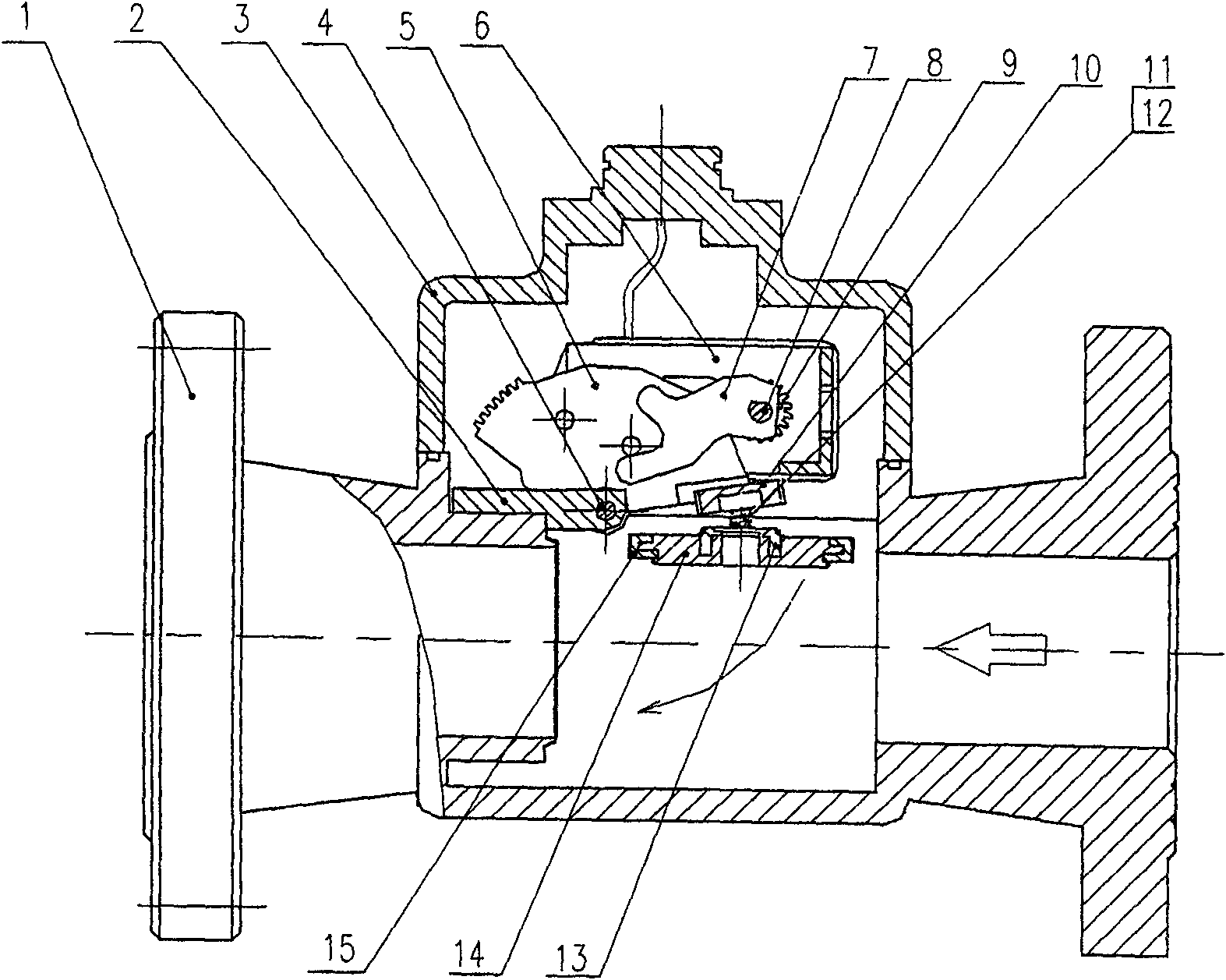

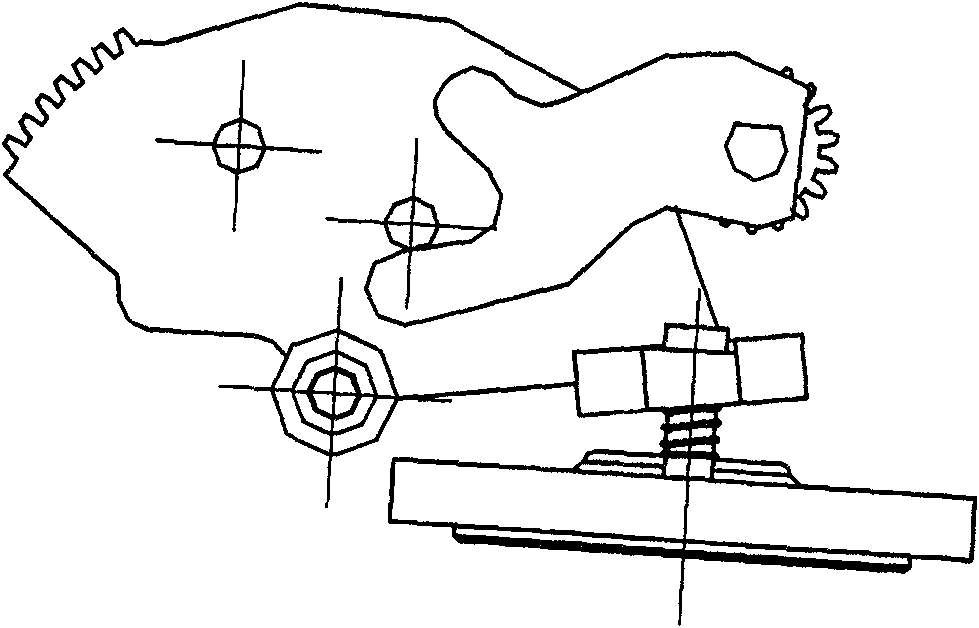

The invention discloses a flap type gas motor valve. The flap type gas motor valve comprises a valve body, an upper shell and a valve cover, wherein the valve body is provided with a core seat; a sector gear plate is arranged on the core seat through a sector gear shaft; a reduction box component is arranged on the core seat and drives a main drive gear to rotate through a coaxial clutch structure; a main drive gear shaft is provided with a coaxial shifting fork which rotates along with the main drive gear; the sector gear plate is connected with the valve cover; a pilot valve structure is additionally designed in the middle of the valve cover; and a pilot valve cover is connected with the valve cover through a pilot valve cover guide post and a spring. The flap type gas motor valve is mainly used for a gas pipeline with an aperture of between DN50 and DN150.

Description

Flap type gas motor valve technical field The invention relates to a motor valve used for gas cut-off control on a gas pipeline, in particular to a DN50-DN150 series flap type gas motor valve. Background technique On the DN50-DN150 caliber gas pipeline, various types of gas cut-off motor valves are used. According to the valve structure, there are gate valves, globe valves, check valves (or check valves), plug valves, butterfly valves, and ball valves. And other types, in the process of gas transmission, they generally produce a large pressure loss (referred to as pressure loss); among them, the ball valve is a type that is more commonly used in recent years, mainly because the pressure loss generated by the ball valve is relatively large. Small, that is, the gas delivery pressure loss to the gas pipeline is small. The embodiment of gas transmission and distribution capacity is mainly the stability or guarantee of gas transmission pressure, which can ensure that gas user...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16K1/20F16K31/04F16K31/53

Inventor 杨磊郭刚

Owner 广州金燃智能系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com