Liquid heating device

A heating device and liquid technology, applied in the direction of fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems that affect the safety of equipment operation, low-temperature stagnant water, and not completely solve the problem of yin and yang water, so as to solve the dead angle of convection and low temperature Dead water, increased tempo and speed, easy to update water quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

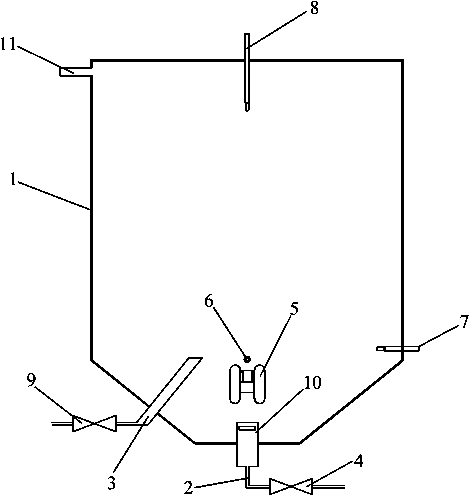

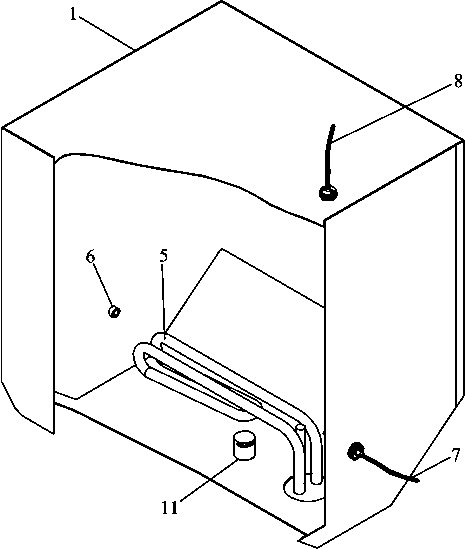

[0034] The structural features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

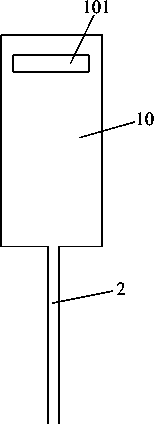

[0035] see figure 1 , figure 2As shown, the liquid heating device of the present invention includes a heating container 1, the heating container 1 is provided with a water supply pipe 2 and a water outlet pipe 3, the water supply pipe 2 is connected to an external water source through a water inlet valve 4, and the heating container 1 is provided with An electric heating tube 5 and a temperature sensor 6, the bottom of the side wall of the heating container 1 is conical, the heating container 1 is respectively provided with a low liquid level sensor 7 and a high liquid level sensor 8, and the water supply pipe 2 is formed by the heating container 1 The bottom of the electric heating pipe 5 and the temperature sensor 6 are sequentially arranged above the outlet of the water supply pipe 2, and the signal output terminals of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com