Weighing error monitoring method of electronic scale

An electric scale and error technology, which is applied in the field of monitoring the weighing error of electric scales on a mixed wire line, can solve problems such as electric weighing and weighing deviation, process accidents, etc., and achieves the effect of reducing the possibility and facilitating timely adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

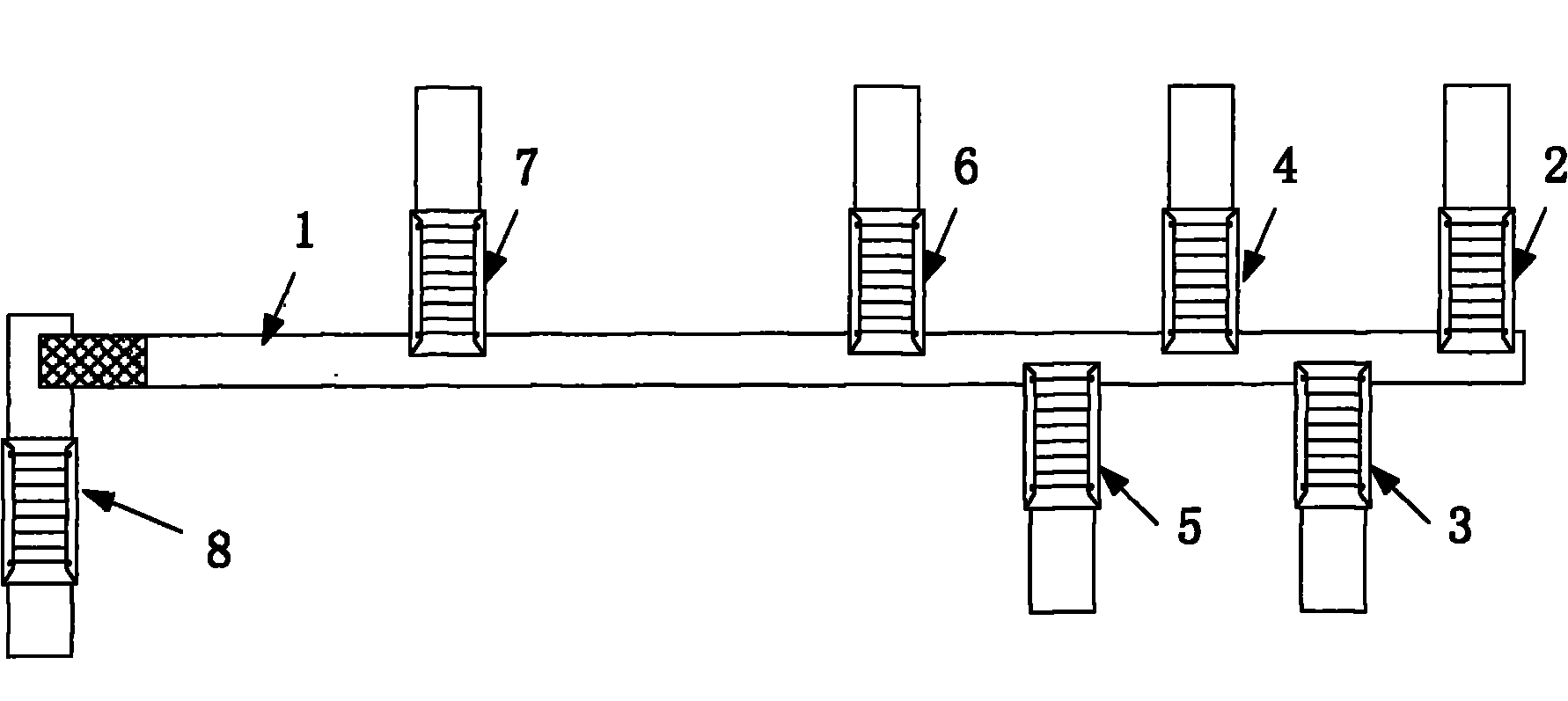

[0038] In order to facilitate the understanding of the application scenarios of the present invention, by figure 1 A schematic diagram of on-site simulation of the mixed silk line of the present invention is provided. exist figure 1 Among them, each blending scale is arranged on the upper and lower sides of the shredded tobacco conveyor belt 1 running from right to left. It can be seen that the blending scale includes the main scale after drying 3, the small wire electronic scale 2, the stem silk scale 5, the expanded silk scale 4, the recycled short silk scale 6 and the side silk thread proportioning scale 7, and the distance from the fragrance adding scale 8 Each is different, so the delay time is also different, which needs to be obtained by testing.

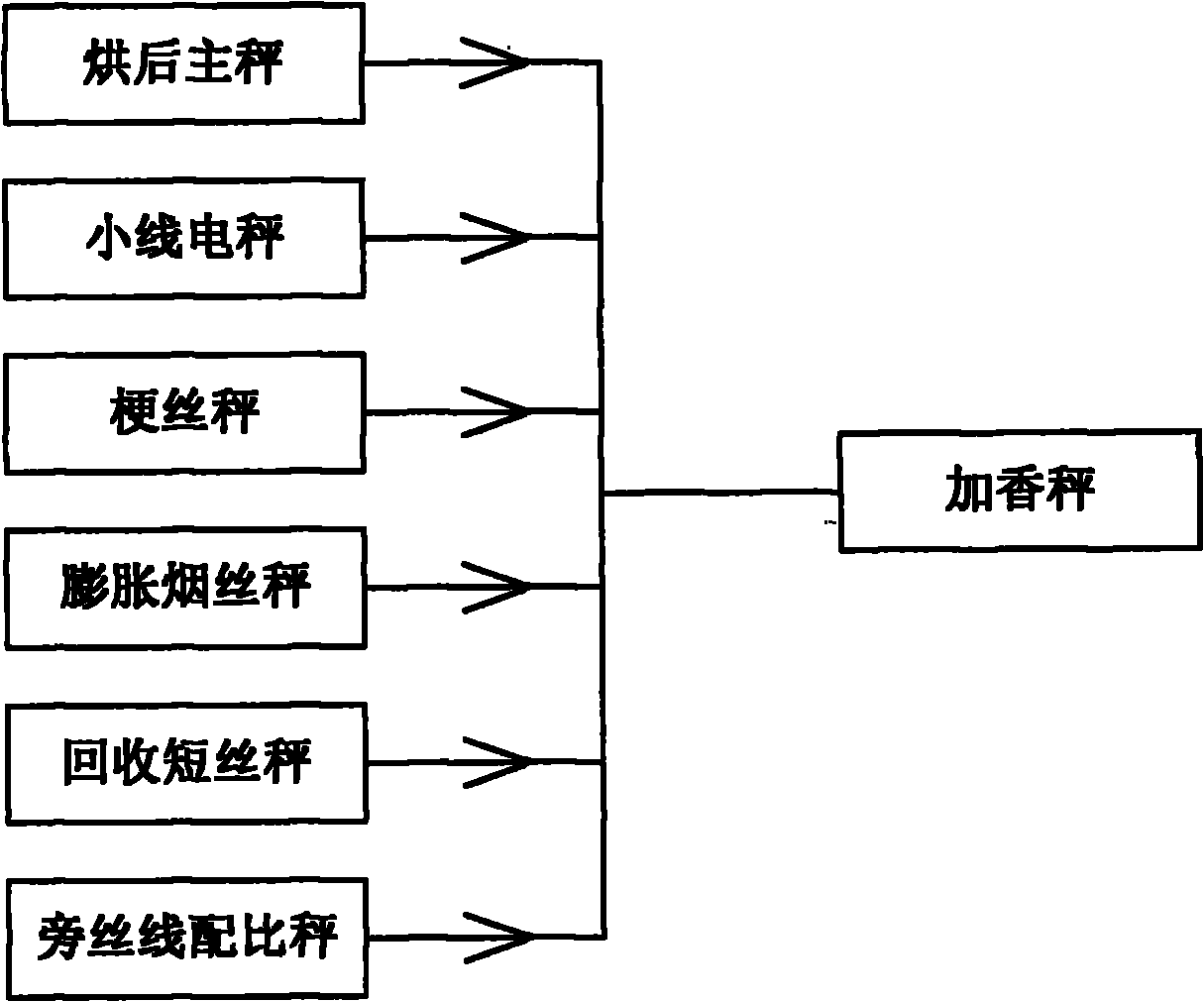

[0039] like figure 2 As shown, it is a schematic diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com