Machine vision-based intelligent detection method for surface defect of bottle cap

A technology for intelligent detection and surface flaws, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as time-consuming, difficult fast image matching detection, unstable detection quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

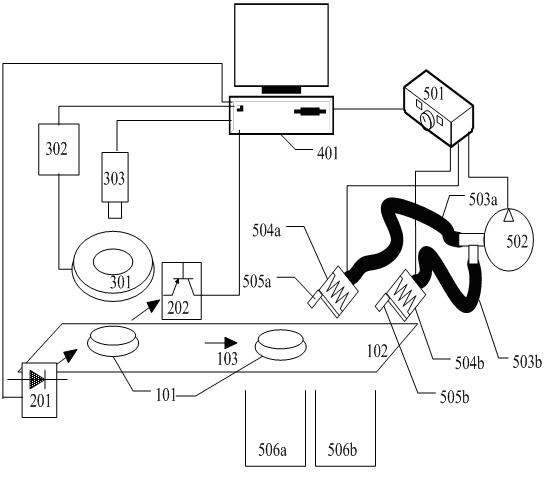

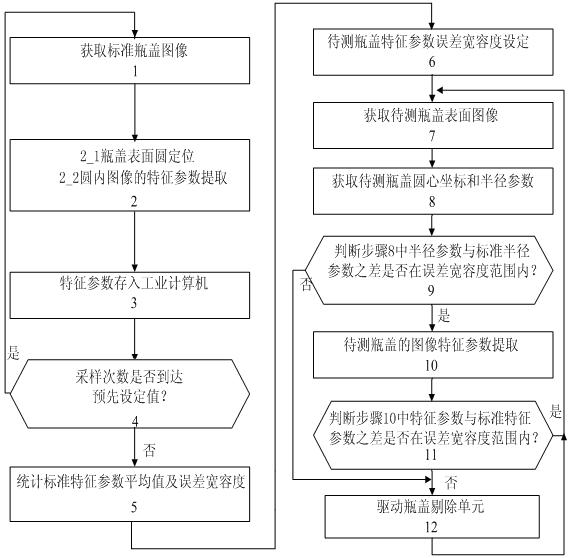

[0041] see figure 1 A device for an intelligent detection method for surface defects of bottle caps based on machine vision, characterized in that it includes photoelectric sensor units (201, 202), imaging systems (301, 302, 303), industrial computers (401) and rejecting units (501, 502 , 503a, 503b, 504a, 504b, 505a, 505b, 506a, 506b). In the figure, 101, 102 and 103 are respectively bottle caps, bottle cap production workpiece conveyor belts and conveyor belt direction indicators. The photoelectric sensor unit includes a photoelectric sensor transmitting end (201) and a photoelectric sensor receiving end (202), which are respectively installed on both sides above the workpiece conveyor belt to detect whether the workpiece is in place, so as to generate a pulse signal and send it to the industrial computer (401), The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com