Body optimization design method of light-weight large-stiffness fine blanking press machine

A press with high stiffness technology, applied in the field of fine blanking presses, can solve the problems of huge design cost, poor dynamic characteristics, long cycle, etc., and achieve the effect of reducing cycle and cost, reliable static indicators, and low cost

Active Publication Date: 2011-06-15

WUHAN UNIV OF TECH

View PDF2 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It may lead to problems such as excessive mass, insufficient strength and stiffness of key parts, and poor dynamic characteristics.

The traditional design process not only makes the product design cycle longer, but also the design cost is huge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

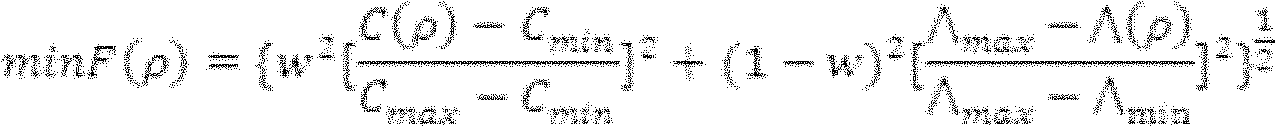

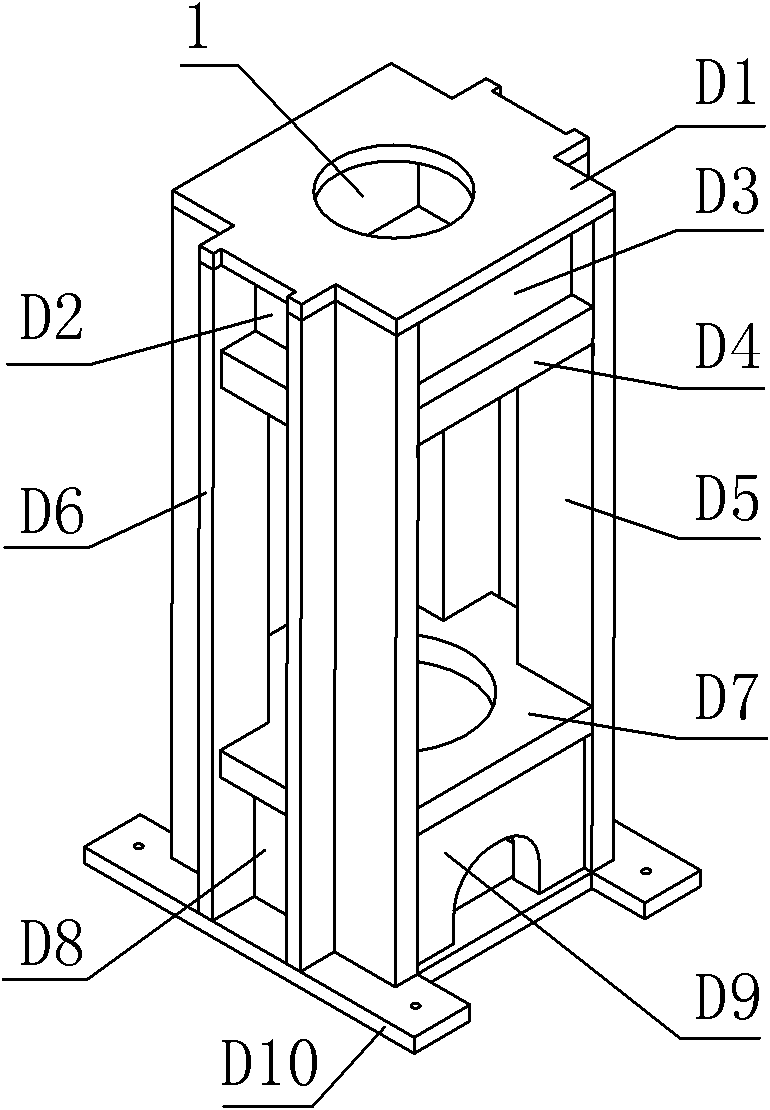

The invention belongs to the technical field of fine blanking press machines, and particularly relates to a body optimization design method of a light-weight large-stiffness fine blanking press machine. The body optimization design method is characterized by comprising the following steps: (1) coarsely designing the body of the fine blanking press machine to obtain a coarse CAD (computer aided design) model; (2) determining whether the coarse CAD model of the step (1) can be optimized according to the strain cloud picture and the stress cloud picture of the coarse-designed body, and carrying out the next step if the coarse CAD model can be optimized; (3) optimizing the stiffness and the natural frequency of the coarse-designed body to find the optimization space of the stiffness and the natural frequency; (4) optimizing a plurality of targets of the coarse-designed body by a compromise programming method; (5) optimizing the size of the machine body optimized by topology; and (6) optimizing the size of the body model of the step (5) by an adaptive response surface method to obtain the optimized body model of the fine blanking press machine. The method can ensure reliable dynamic indexes and static indexes, and can lower the cost maximally.

Description

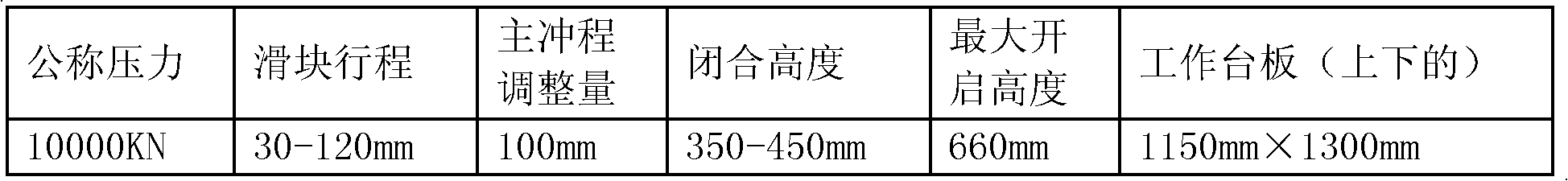

An Optimal Design Method for Lightweight and High Rigidity Fineblanking Press Body technical field The invention belongs to the technical field of fine-blanking presses, and in particular relates to an optimal design method for a fuselage of a lightweight and high-rigidity fine-blanking press. Background technique As a precision forming technology, fine blanking has the characteristics of high quality, high efficiency and low consumption. It has been widely used in the fields of automobiles, motorcycles, instruments and meters, light industrial machinery, household appliances and office equipment. Large fine blanking presses are essential basic manufacturing equipment in the fields of automobiles, aerospace, weapons and high technology, and one of the major equipment that must be mastered independently to ensure economic and national defense security. The research and development of fine blanking equipment with a large tonnage of more than 10,000KN is in a blank state in C...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F17/50

Inventor 华林胡俊伟兰箭赵玉民毛华杰

Owner WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com