Method for preparing molecular junction by polydimethylsiloxane stencil printing

A technology of polydimethylsiloxane and stencil printing, which is applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve problems such as deformation of graphic structures, influence of device yield, short circuit of upper and lower electrodes, etc., to achieve Avoiding severe uncertainty, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

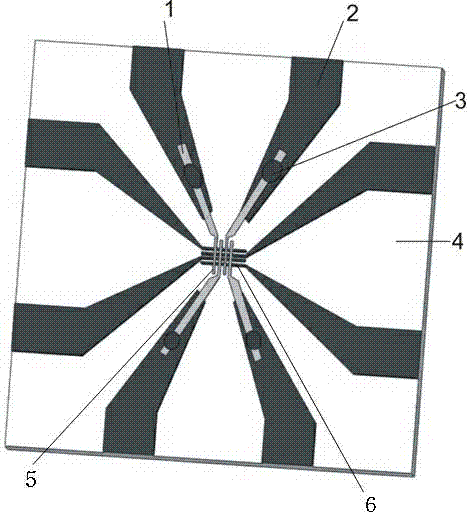

Image

Examples

Embodiment 1

[0032] The steps of the method for preparing molecular knots by polydimethylsiloxane template printing are as follows.

[0033] (1) Cleaning the Si substrate

[0034] On the upper and lower sides of a pure Si(100) substrate, 250 nm thick SiO was grown at 1150 °C by dry oxygen oxidation 2 layer, the oxidation time is 5 hours. Dip the cut-sized Si substrate into the piranha solution at 65°C, take it out after 15 minutes, and then immerse it in deionized water, acetone and alcohol successively and clean it with ultrasonic wave for 4 minutes respectively.

[0035] Note: the piranha solution is pure H 2 SO 4 and H at a mass concentration of 30% 2 o 2 The mixture mixed at a ratio of 4:1 by volume is a highly oxidatively active corrosive solution that may react violently with organic materials. Operators should pay attention to physical protection (wear goggles, lab coats, rubber gloves and work in a chemical fume hood).

[0036] (2) Photolithography

[0037] Spin-coat positi...

Embodiment 2

[0053] The steps of the method for preparing molecular knots by polydimethylsiloxane template printing are as follows.

[0054] (1) Cleaning the Si substrate

[0055] On the upper and lower sides of a pure Si(100) substrate, 300 nm thick SiO was grown at 1200 °C by dry oxygen oxidation 2 layer, the oxidation time is 6 hours. Dip the cut-sized Si substrate into piranha solution at 80°C, take it out after 10 minutes, and then immerse it in deionized water, acetone and alcohol successively and clean it with ultrasonic wave for 5 minutes respectively.

[0056] Note: the piranha solution is pure H 2 SO 4 and H at a mass concentration of 30% 2 o 2 The mixture mixed at a ratio of 4:1 by volume is a highly oxidatively active corrosive solution that may react violently with organic materials. Operators should pay attention to physical protection (wear goggles, lab coats, rubber gloves and work in a chemical fume hood).

[0057] (2) Photolithography

[0058] Spin-coat positive r...

Embodiment 3

[0073] The steps of the method for preparing molecular knots by polydimethylsiloxane template printing are as follows.

[0074] (1) Cleaning the Si substrate

[0075] On the upper and lower sides of a pure Si (100) substrate, a 200nm thick SiO is grown at 1100°C by dry oxygen oxidation. 2 layer, the oxidation time is 4 hours. Dip the cut Si substrate into the piranha solution at 50°C, take it out after 20 minutes, and then immerse it in deionized water, acetone and alcohol successively and clean it with ultrasonic wave for 3 minutes respectively.

[0076] Note: the piranha solution is pure H 2 SO 4 and H at a mass concentration of 30% 2 o 2 The mixture mixed at a ratio of 4:1 by volume is a highly oxidatively active corrosive solution that may react violently with organic materials. Operators should pay attention to physical protection (wear goggles, lab coats, rubber gloves and work in a chemical fume hood).

[0077] (2) Photolithography

[0078] Spin-coat positive re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com