Isokinetic smoke dust sampling device and sampling method

A sampling device, smoke and dust technology, applied in the direction of sampling devices, measuring devices, instruments, etc., can solve the problem of inability to continuously reflect the change of smoke and dust, the inability to meet the requirements of on-site process adjustment in stages, and the inability of the air pump to achieve constant-speed pumping, etc. problem to achieve the effect of preventing test abort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

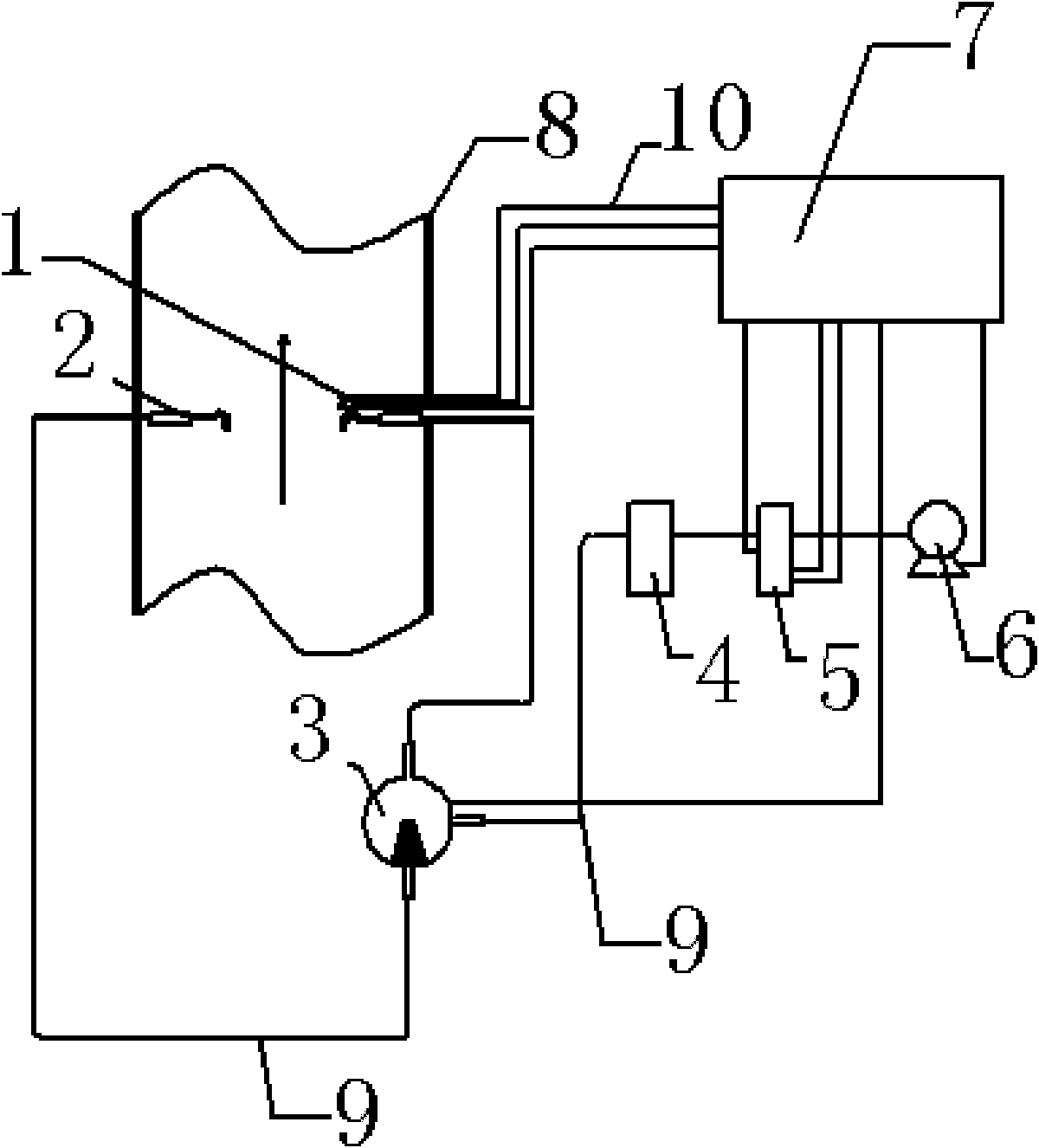

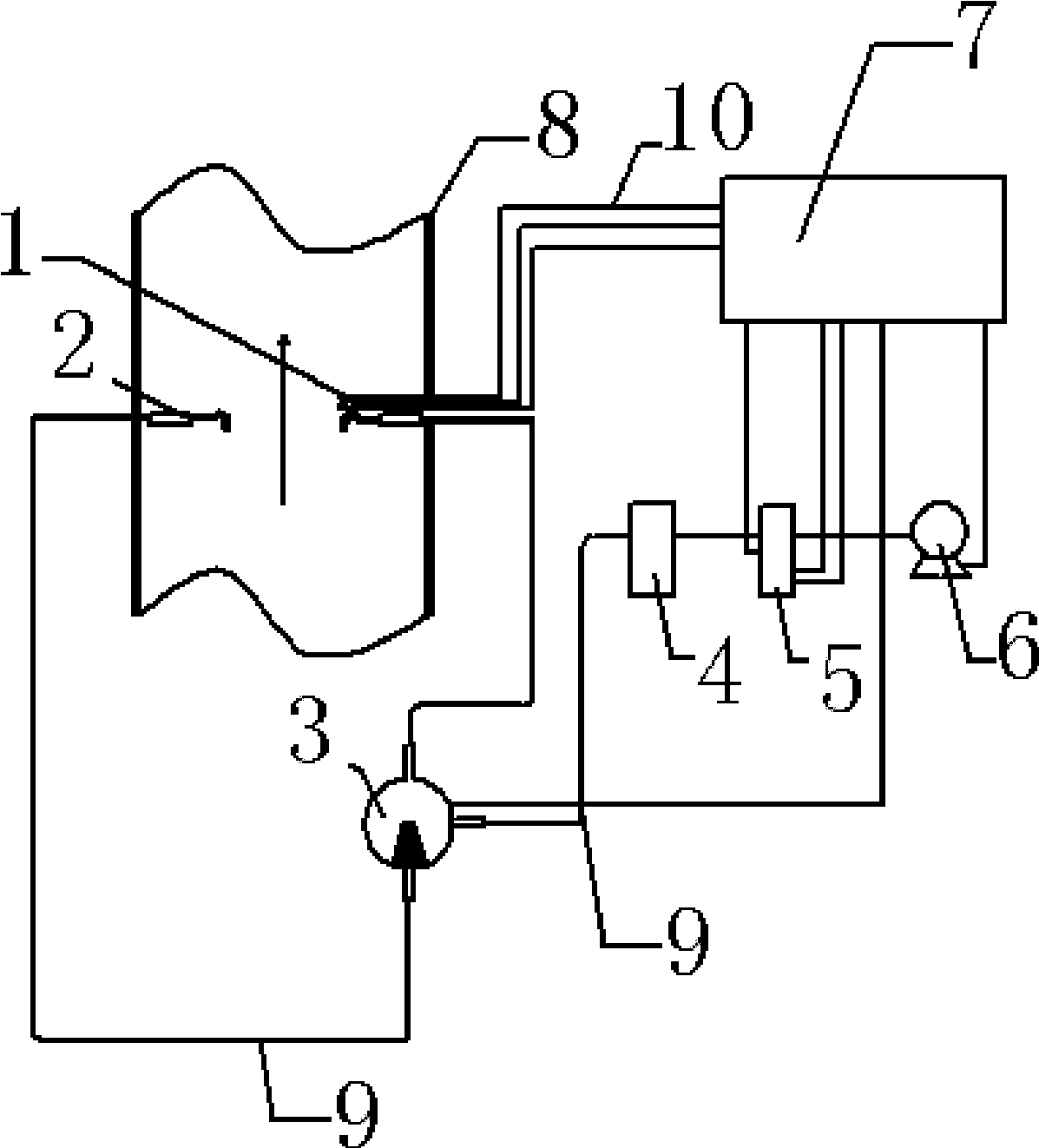

[0033] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the mutual position and connection relationship between the various parts involved, are further described in detail, so as to help those skilled in the art to understand the conception of the present invention , Technical solutions have a more complete, accurate and in-depth understanding.

[0034] Such as figure 1 As shown, the constant-velocity smoke sampling device includes a main sampling gun 1, an auxiliary sampling gun 2, a three-way switching valve 3, a flow meter 5, an air pump 6, a flue 8 and a single-chip microcomputer 7.

[0035] The main sampling gun 1 and the auxiliary sampling gun 2 are arranged inside the flue 8 .

[0036] The main sampling gun 1 is connected to the first port of the three-way switching valve 3 through a smoke hose 9 .

[0037] The secondary sampling gun 2 is connected to the second po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com