Detaching device for thyristor of converter valve

A technology of dismantling device and thyristor, applied in the field of electric power system, can solve problems such as danger and complicated operation of hydraulic dismantling device, and achieve the effects of less auxiliary equipment, simple structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A device for removing a thyristor of a converter valve according to the present invention will be described in detail below with reference to the drawings and embodiments.

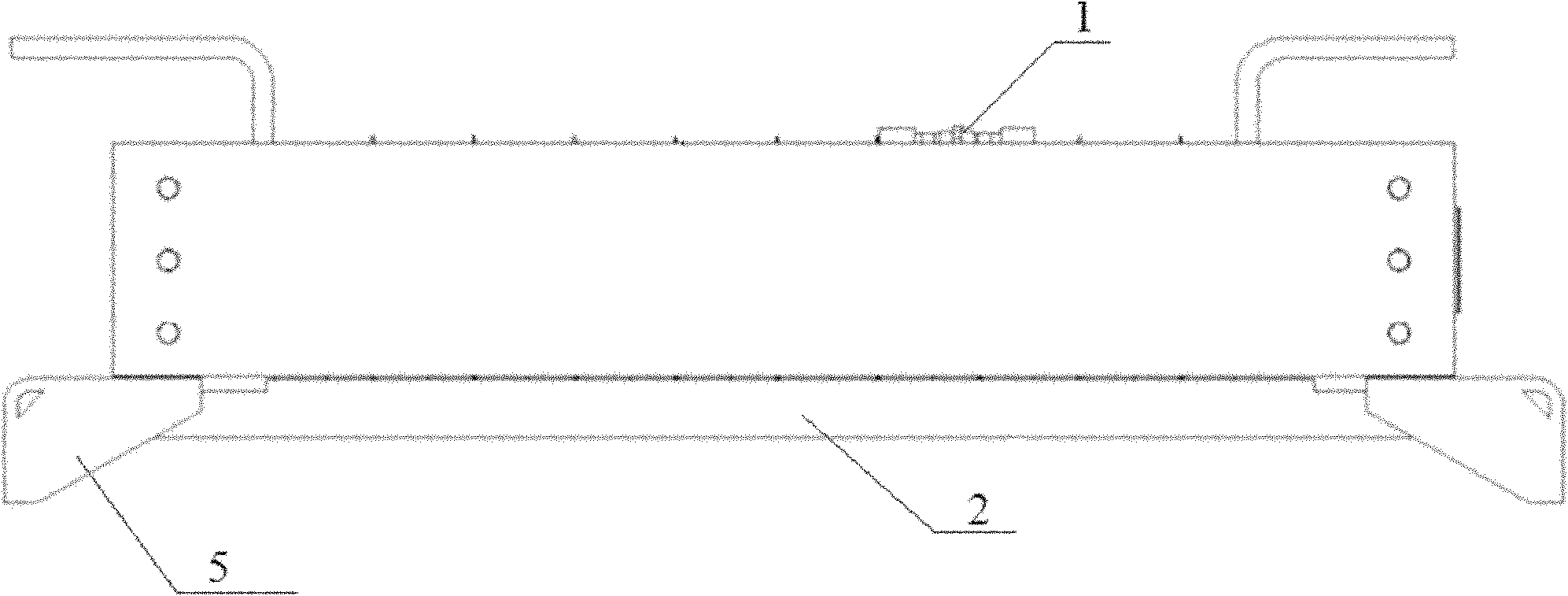

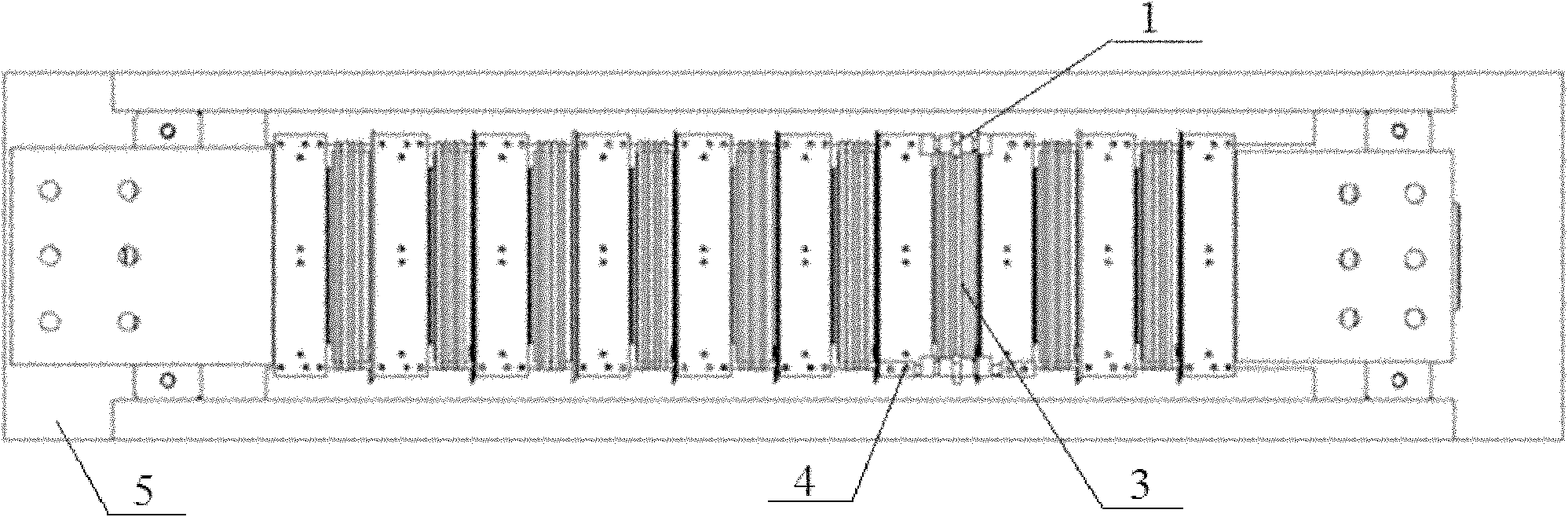

[0023] Such as figure 1 and 2 As shown, a dismantling device for a thyristor of a converter valve according to the present invention includes a support beam 2 and a set of expansion blocks 1, and the support beam 2 and the expansion blocks 1 are independent of each other. Such as image 3 and 4 As shown, the support beam 2 is an aluminum beam with a triangular cross section, which makes the structure lighter. On its facade, there is a round hole at the end, which is fixed on the base 5. The horizontal surface of the support beam contacts the bottom surface of the radiator 4, and after the pressure-fitting force is removed, the support beam plays a role in supporting and positioning the radiator. Such as Figure 5 and 6 As shown, the expansion block 1 is composed of a left-handed stud 1.1, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com