Sulfonation post-treatment method for organic-inorganic composite electrolyte membranes

A technology of inorganic compounding and processing method, which is applied in electrochemical generators, components and circuits of fuel cells, etc., can solve problems such as the decrease of proton conductivity, and achieve the effects of low cost, easy implementation and simple equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

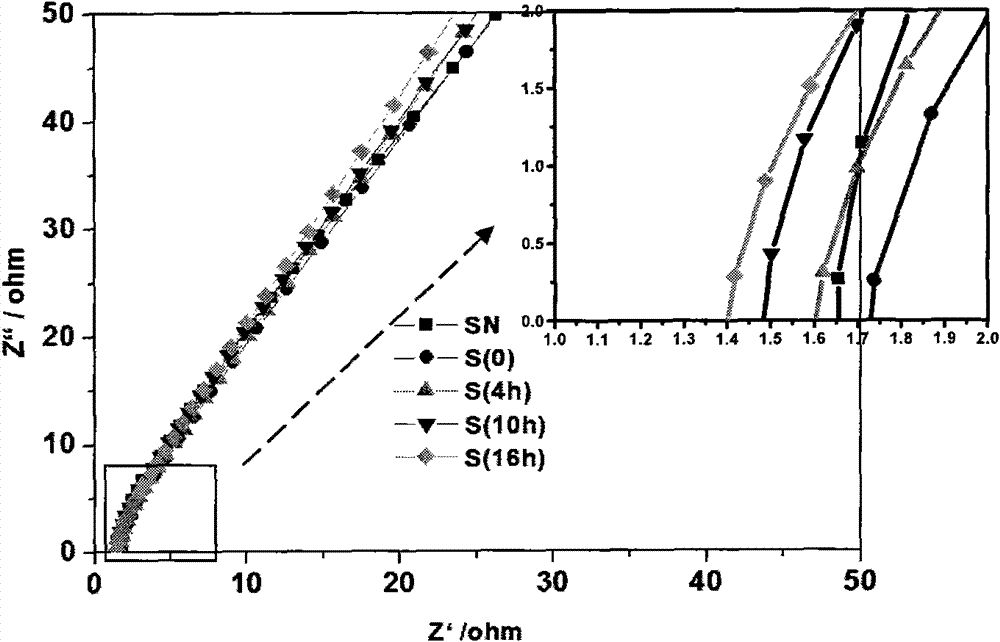

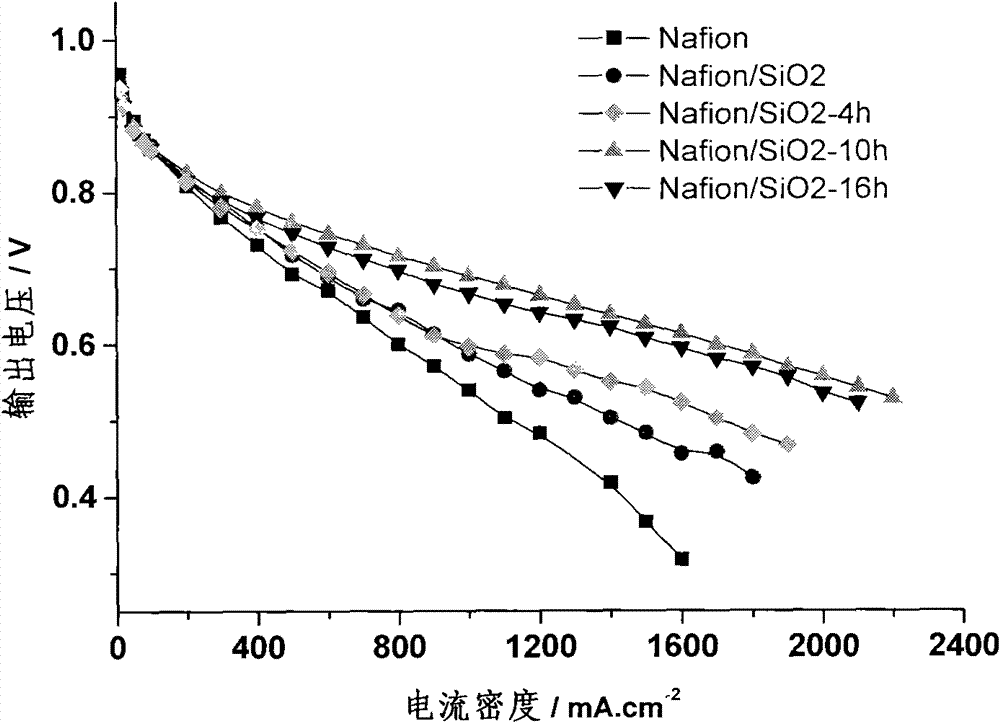

[0030] Take a sheet with an area of 35×35(mm 2 ) Nafion / SiO 2 The composite film was vacuum-dried at 80° C. for 6 hours. Take out the above-mentioned dried composite film and transfer to concentrated sulfuric acid (mass concentration 98%) at 130° C. to cook for a certain period of time (4 hours, 10 hours or 16 hours). After completion, the composite membrane was taken out and washed in deionized water until the washing solution was neutral. The sulfonated organic-inorganic composite membrane was obtained after drying in a vacuum oven at 80°C for 12 hours. After different sulfonation time treatments, the proton conductivity of the obtained sulfonated organic-inorganic composite membranes is as follows: figure 1 shown. The value at the intersection of the impedance curve and the horizontal axis in the figure can represent the membrane resistance, and it can be seen that the resistance of the composite membrane decreases after sulfonation. This shows that after sulfonation...

Embodiment 2

[0032] Take a sheet with an area of 100×270(mm 2 ) Nafion / SiO 2 The composite film was vacuum-dried at 80° C. for 6 hours. The above-mentioned dried composite membrane was taken out and transferred to chlorosulfonic acid (analytical pure) at 80° C. to cook for 10 hours. After completion, the composite membrane was taken out and washed in deionized water until the washing solution was neutral. The sulfonated organic-inorganic composite membrane was obtained after drying in a vacuum oven at 80°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com