Toughening rubber for nylon and preparation method thereof

A technology of rubber and nylon, applied in the field of high-efficiency toughened rubber for nylon and its preparation, can solve the problems of large amount of toughening agent added, affecting the effect of modification, and other properties of nylon, and achieving good compatibility, Good dispersion, improve toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

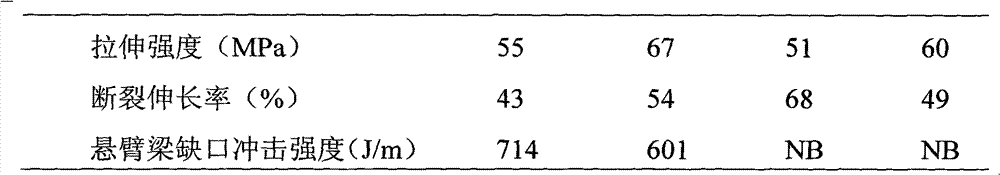

[0019] According to mass percentage, first add 0.40 parts of sodium caprolactam to 90 parts of molten caprolactam monomer, then add 10 parts of nitrile rubber with an average particle size of 0.1 μm, and keep the system at 140 ° C for 60 minutes. Next, filter the mixture with a Buchner funnel, wash the filter cake with water and then dry it in vacuum at 80° C. for 24 hours to obtain a high-efficiency toughened rubber for nylon. Nylon 6 and the high-efficiency toughening rubber for nylon with a weight of 1.5% are melt-blended in an extruder, and after drying the extruded product at 100°C for 5 hours, it is made into a standard sample by an injection molding machine, and its mechanical properties As shown in Table 1.

Embodiment 2

[0021] According to mass percentage, first add 0.83 parts of sodium butyrolactam to 80 parts of molten butyrolactam monomer, then add 20 parts of nitrile silicone rubber with an average particle size of 0.3 μm, and keep the system slightly boiling at 100 ° C 10min. Next, filter the mixture with a Buchner funnel, wash the filter cake with water and then dry it in vacuum at 80° C. for 24 hours to obtain a high-efficiency toughened rubber for nylon. Nylon 4 and the high-efficiency toughening rubber for nylon with a weight of 3.0% are melt-blended in an extruder, and after drying the extruded product at 100°C for 5 hours, it is made into a standard sample by an injection molding machine, and its mechanical properties As shown in Table 1.

Embodiment 3

[0023] According to mass percentage, first add 2.5 parts of sodium laurolactam to 85 parts of molten laurolactam monomer, and then add 15 parts of sodium nitrile rubber with an average particle size of 5.0 μm. Keep the system slightly boiling for 3min. Next, filter the mixture with a Buchner funnel, wash the filter cake with water and then dry it in vacuum at 80° C. for 24 hours to obtain a high-efficiency toughened rubber for nylon. Melt and blend nylon 12 and the high-efficiency toughened rubber for nylon with a weight of 5.0% in an extruder, dry the extruded product at 100°C for 5 hours, and then make a standard sample through an injection molding machine. As shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com