Method for measuring harmful heavy metal substances arsenic and lead in tobacco tipping paper

A technology of cigarette tipping paper and measurement method, which is applied in the preparation of test samples, fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of affecting measurement accuracy, high instrument cost, low anti-interference, etc., and achieve saving Effects on sample processing time, simplification of traditional methods, and improved accuracy

Active Publication Date: 2011-06-29

楚雄市华丽包装实业有限责任公司

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cigarette tipping paper is solid, and the main components are mostly inorganic elements and organic elements. The acid system ratio is not properly selected and the traditional microwave digestion method cannot complete the decomposition of the sample, and the interference is large. The acid system ratio is wrong. Improper method selection will directly affect the accuracy of the measurement, low anti-interference and low accuracy during the measurement, and the cost of the instruments used in the above-mentioned traditional methods is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

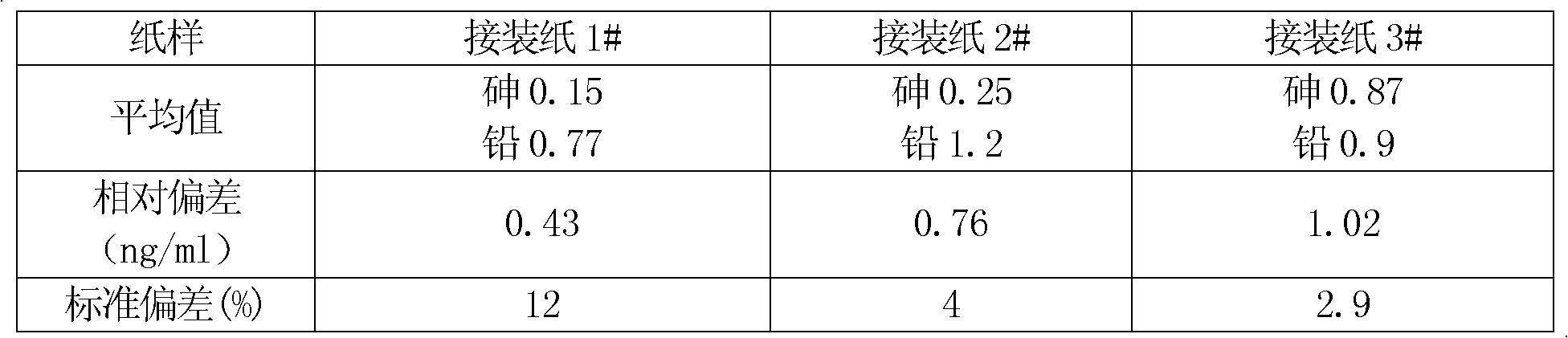

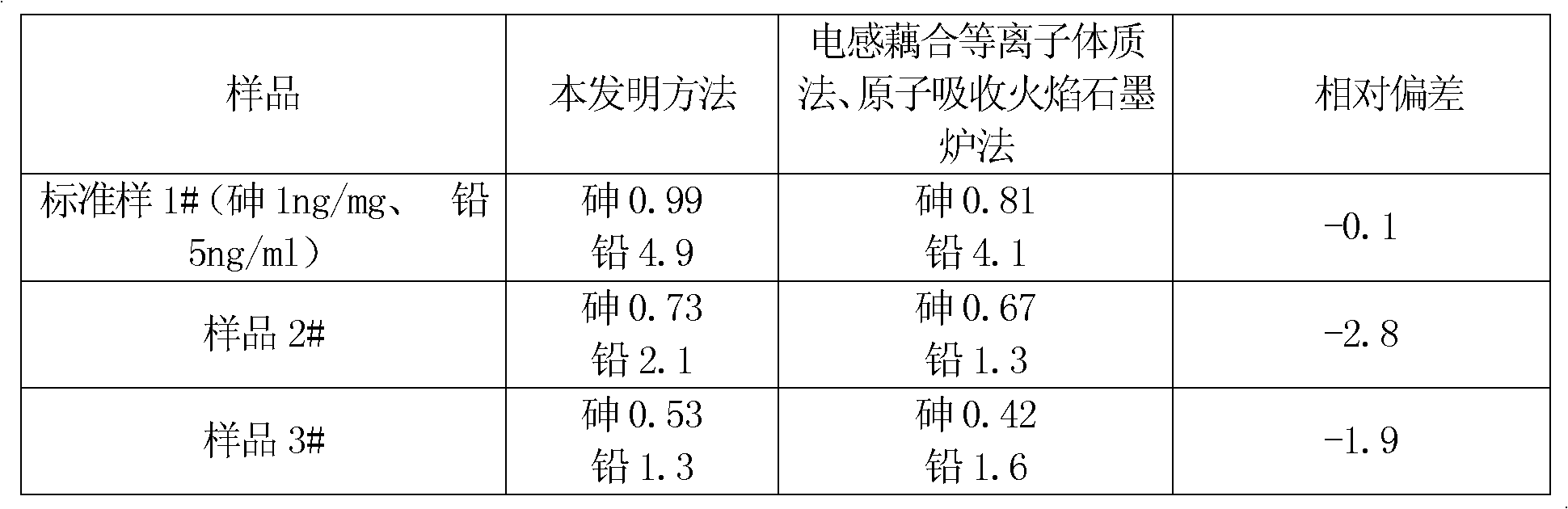

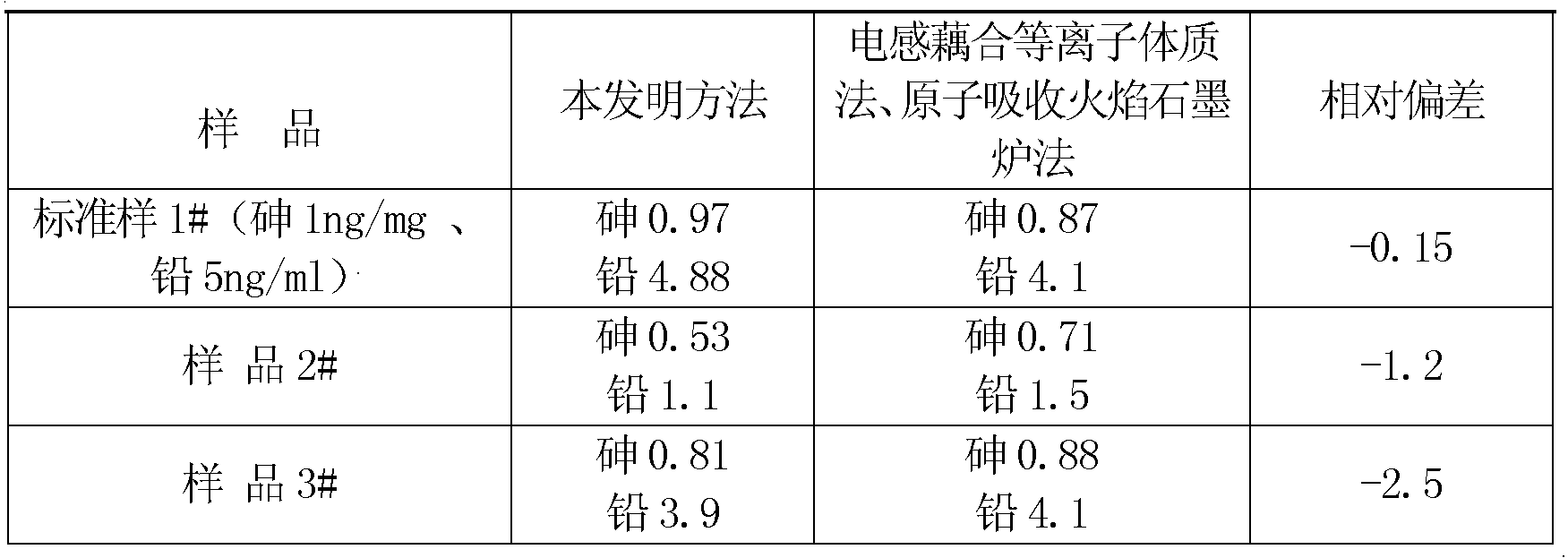

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for measuring trace heavy metal arsenic and lead in tobacco tipping paper, and in particular relates to a method for measuring the content of arsenic and lead in the tobacco tipping paper by using a calibrated atomic fluorescence spectrophotometer after the tobacco tipping paper is digested by nitric acid and sulfuric acid on an electric heating plate or in an electric furnace. The conventional method is simplified, the acid is not required to be driven repeatedly, sample treatment time can be saved, the interference of antimony and nickel elements in a detection result can be effectively eliminated, a tipping paper sample is quickly and efficiently measured, measuring accuracy is improved, and the method is a novel and applicable electric heating nitric acid digestion atomic fluorescence quantitative measuring method for the content of the arsenic and the lead in the tobacco tipping paper.

Description

A method for the determination of harmful heavy metals arsenic and lead in tipping paper for cigarettes technical field The invention discloses a method for determining heavy metal traces of arsenic and lead in tipping paper for cigarettes. Specifically, it uses an electric heating plate (electric furnace) to digest nitric acid and sulfuric acid, and then uses a calibrated luminescent spectrophotometer to measure cigarette tipping paper. Paper contains arsenic and lead. Background technique Cigarette tipping paper is one of the cigarette materials that smokers directly contact with the oral cavity. The harmful heavy metals arsenic and lead in cigarette tipping paper may directly enter the human body through oral contact, endangering the health of smoking consumers. Therefore, the YC171-2008 "Tipping Paper for Cigarettes" standard lists arsenic and lead in tipping paper for cigarettes as the primary monitoring elements. At present, domestic arsenic detection methods are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/64G01N1/28G01N1/44

Inventor 王守成段斌陈芝国尹磊高伟

Owner 楚雄市华丽包装实业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com