Method for Automatically Establishing Interlayer Error Measurement Programs in Batches in Photolithography Process

A lithography process and lithography layer technology, applied in the field of lithography, can solve problems such as increasing measurement time, and achieve the effects of reducing manufacturing time, improving efficiency, and reducing human operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

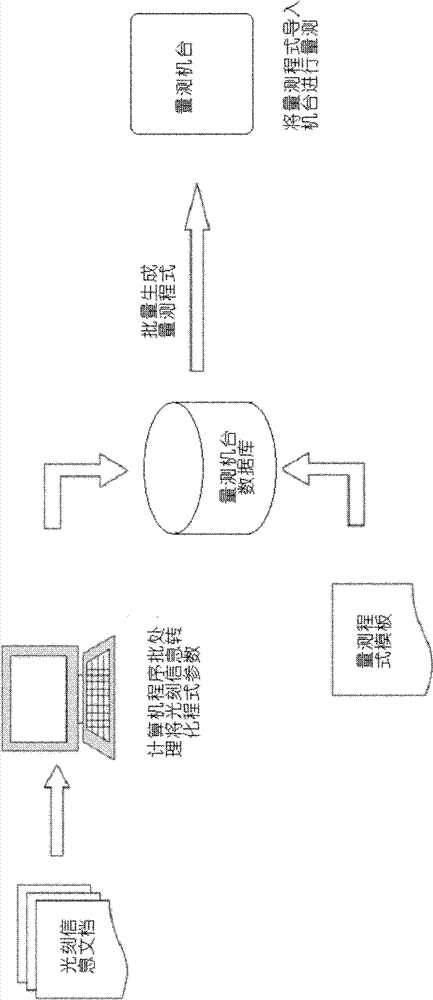

[0018] Such as figure 1 , a method for measuring an error between photolithography layers in a photolithography process, comprising the steps of:

[0019] 1) Make photolithographic information documents;

[0020] 2) Convert the lithographic information into a program parameter file;

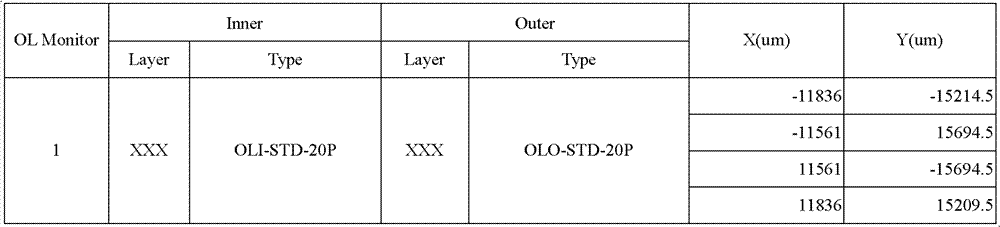

[0021] 3) Create a template for a common measurement program, including

[0022] 3.1) A common reference pattern for product design;

[0023] First draw a reference pattern at a fixed position in the photomask design drawing as a mark for alignment and identification of the measuring machine; then import the reference pattern and its coordinates in the exposure area into the database of the measuring machine;

[0024] 3.2) Set common environmental parameters for product measurement;

[0025] 4) Import the program parameters into the database of the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com