Method for reducing plasma induced damage in HDP CVD (high-density plasma chemical vapor deposition) process

A plasma and process technology, applied in the field of plasma-induced damage, can solve problems such as metal layer damage, poor yield and reliability of semiconductor devices, and impact, so as to improve yield and reliability, avoid direct bombardment, and reduce PID The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the objects, technical solutions and advantages of the present invention clearer, the present invention is described in further detail below with specific examples and with reference to the accompanying drawings.

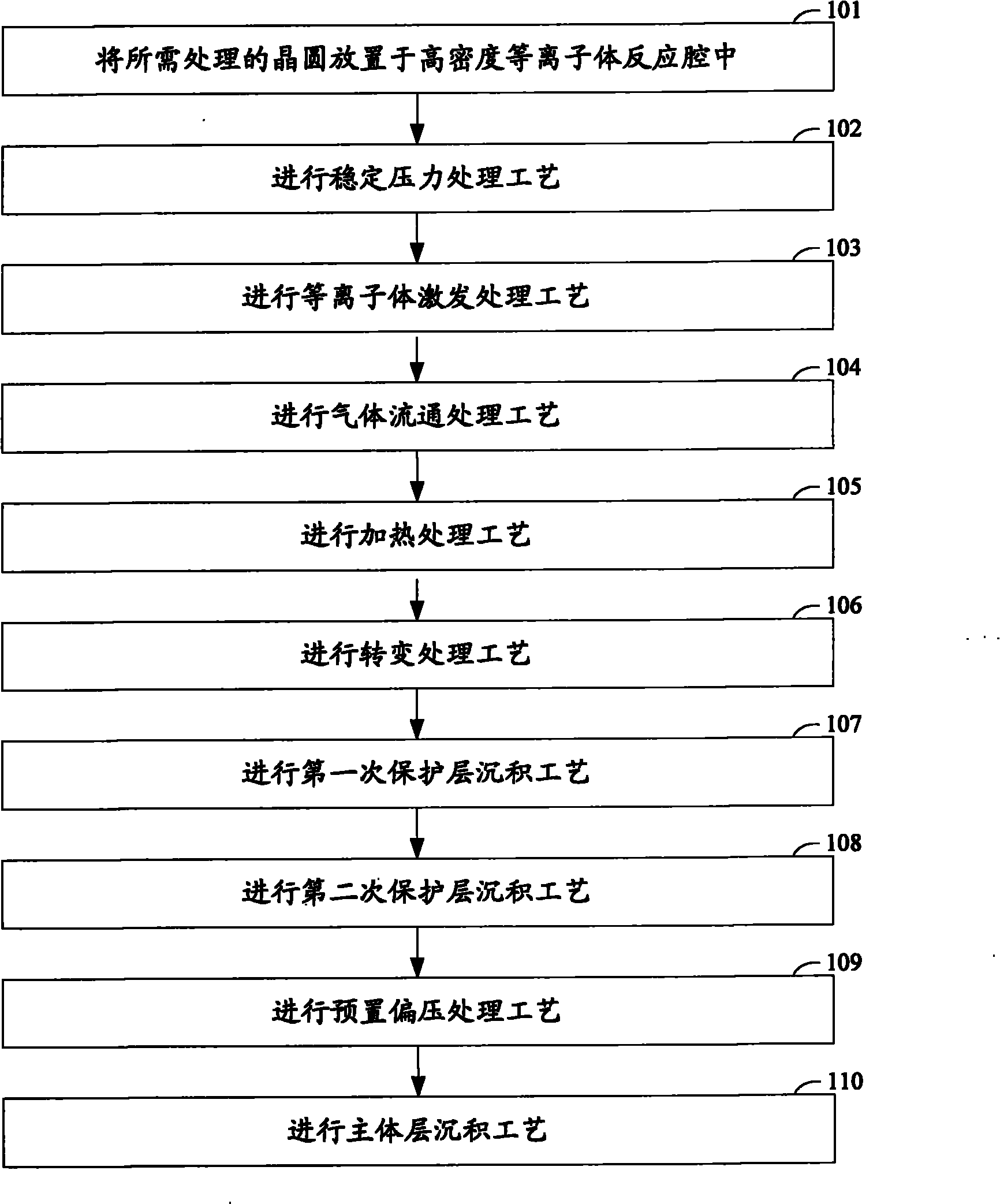

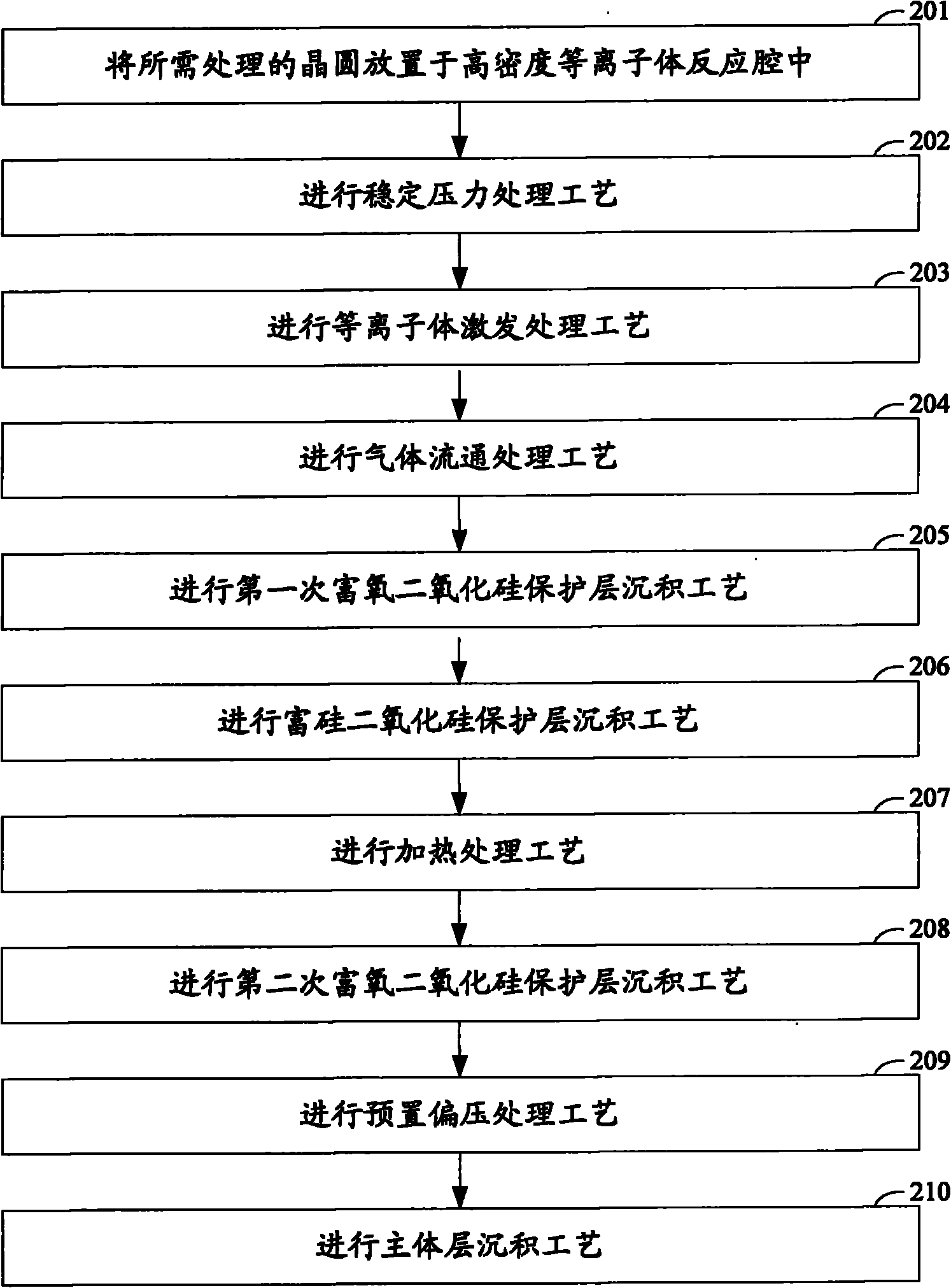

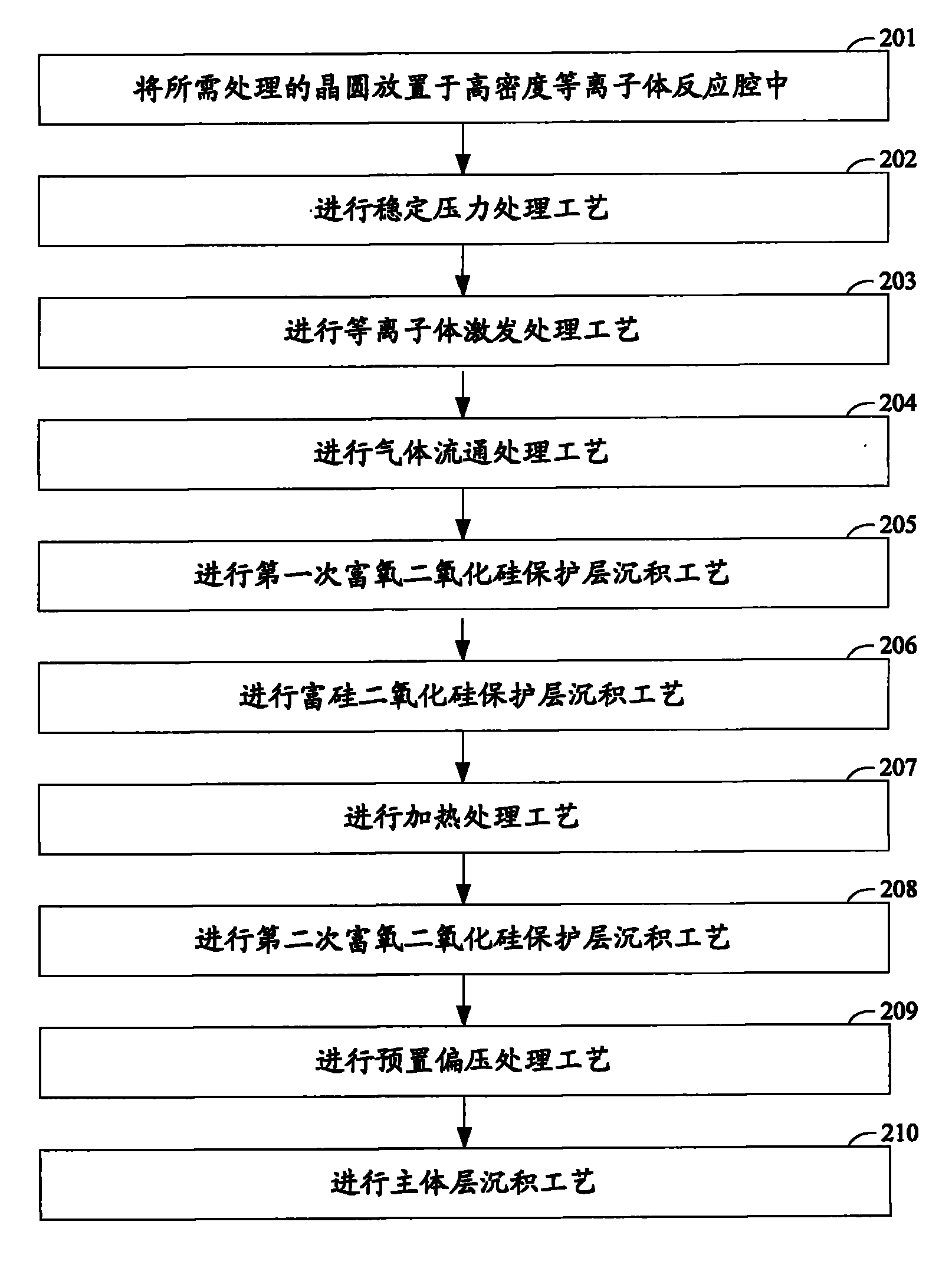

[0052] figure 2 It is a flowchart of the HDP CVD process in the embodiment of the present invention. Such as figure 2 As shown, the HDP CVD process in the embodiment of the present invention includes the steps as follows:

[0053] Step 201, placing the wafer to be processed in a high-density plasma reaction chamber.

[0054] Step 202, performing a pressure stabilization process.

[0055] In this step, the reaction gas is fed into the high-density plasma reaction chamber, that is, the required reaction gas is input into the high-density plasma reaction chamber through the gas nozzle. This step lasts about 10 seconds, so that the pressure in the high-density plasma reaction chamber reaches a preset stable value. In an embodiment of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com