Casting liquid level measurement in crystallizer by using fiber optic measuring method

一种结晶器、结晶器铜板的技术,应用在测量热量、物理变量测量的液位指示器、指示设备/测量设备的配置等方向,能够解决易受到干扰、不可能得到铸造液面波等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

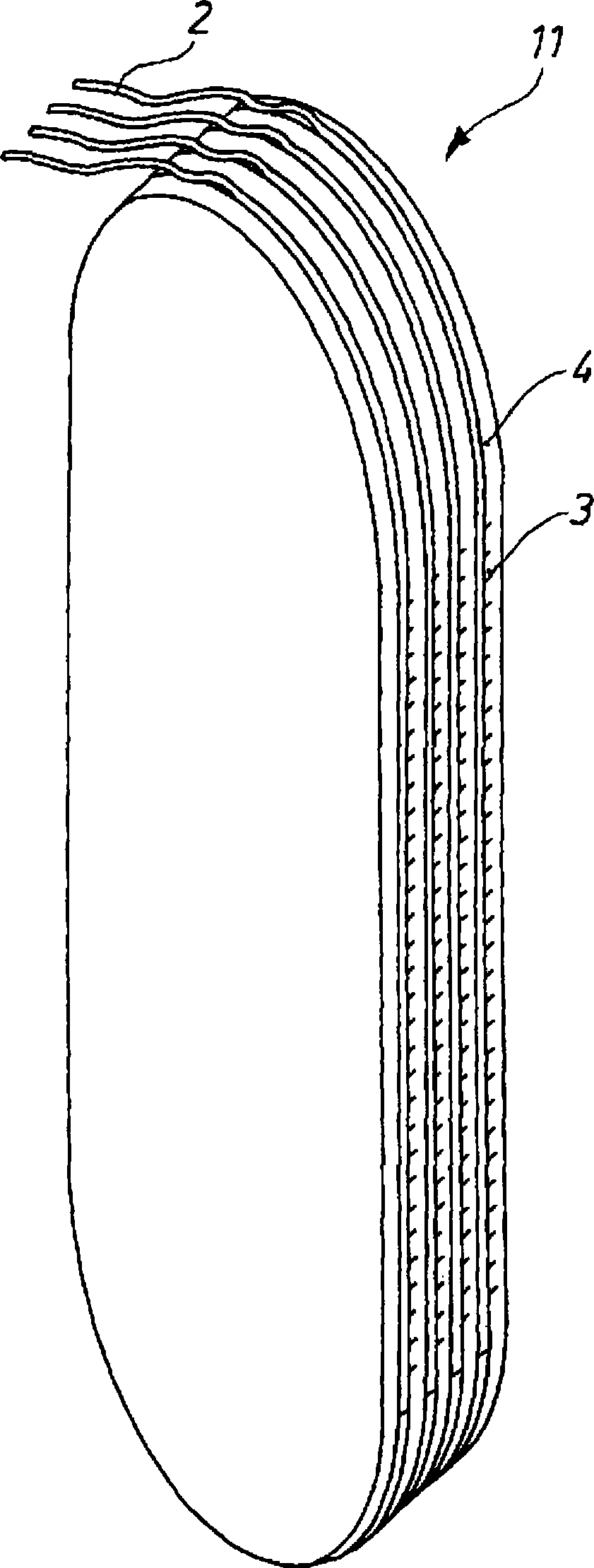

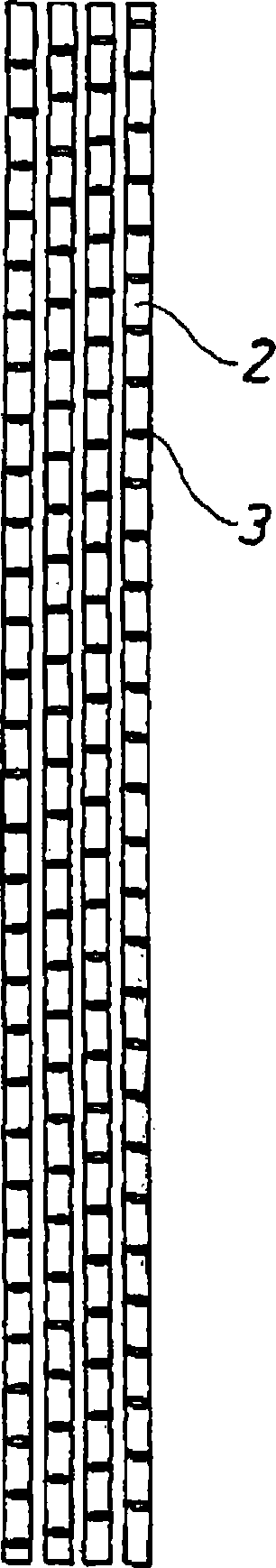

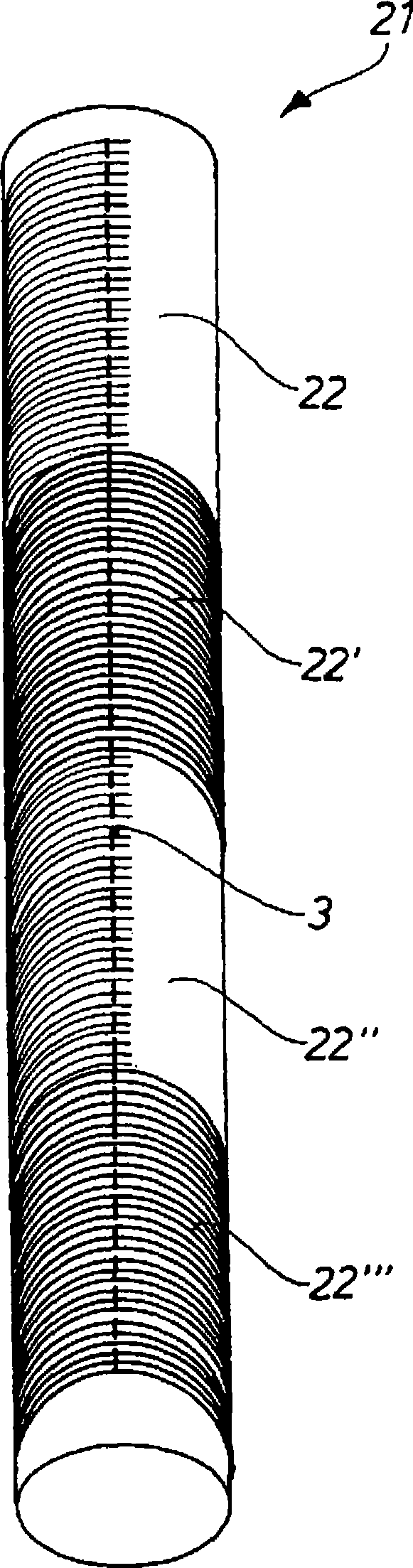

[0043] exist Figure 1a An embodiment according to the invention of a detector 11 is shown in . The substantially square base body of the detector 11 can be seen, which is rounded into an arc at the upper and lower ends. Arranged in the detector 11 are four slots 4 , in which an optical waveguide (optical fiber) or fiber optic sensor 2 is arranged in each case. Furthermore, a measurement point 3 is shown at which the temperature can be determined. For example, the detector 11 can be installed in a groove in the side of the mold copper plate facing away from the melt, so that the optical waveguide 2 is oriented in the direction of the melt. In this case, the detector 11 is installed in such a way that the optical waveguide 2 is in direct contact with the copper plate and is arranged in the direction of the melt between the water cooling of the copper plate and the melt. The shown detector 11 can also have other geometries as long as it fits into the groove of the mold copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com