Bainite steel and methods of manufacture thereof

A manufacturing method and technology of super bainitic steel, applied in the field of phase transformation microstructure, which can solve the problems of high energy cost, machining of difficult bainitic steel, hole opening and forming, long production time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

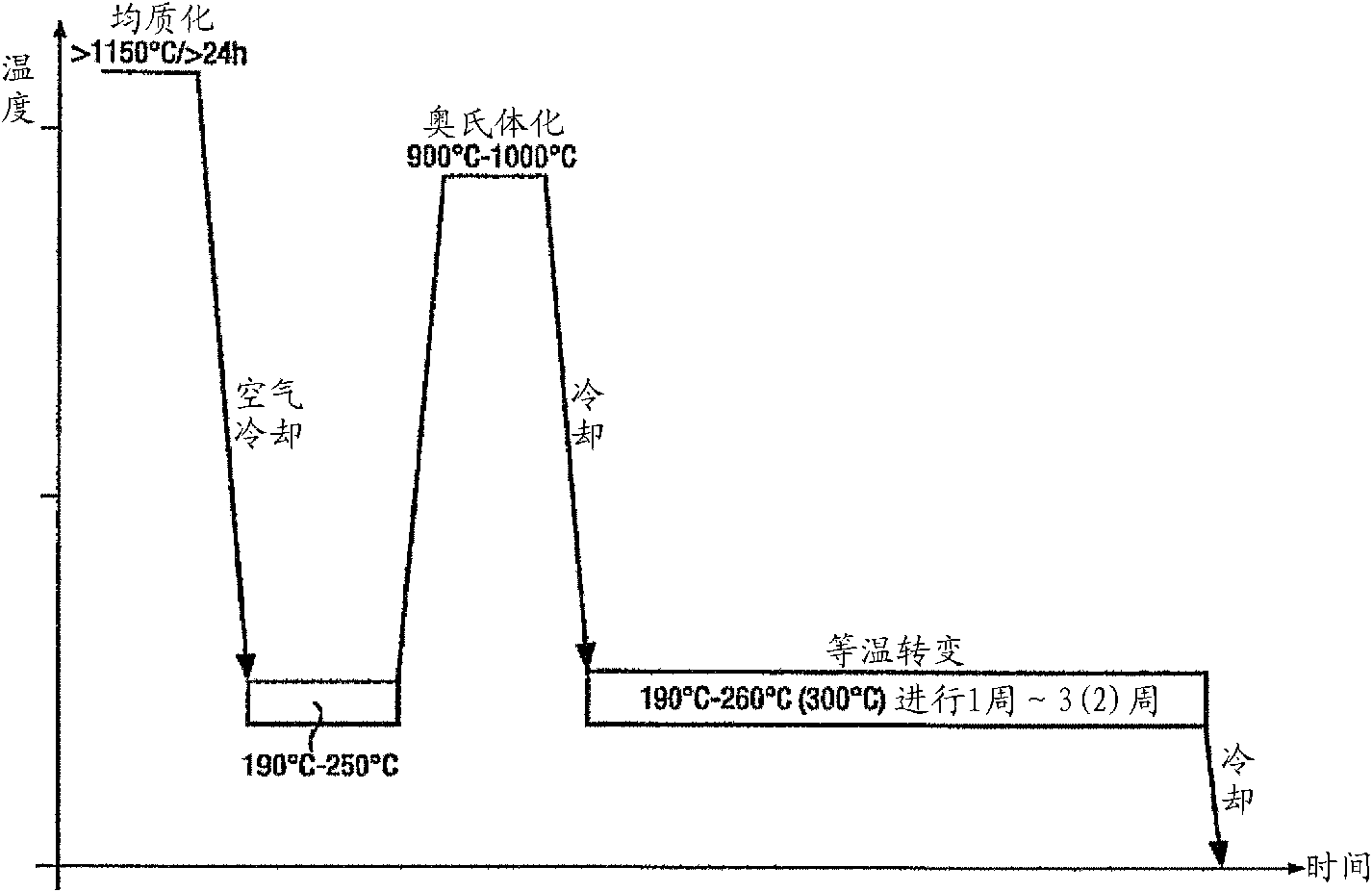

[0070] exist Figure 1A , the material is homogenized above 1150°C and air cooled to a temperature between 190°C and 250°C. The samples shown must be small samples with high surface area. The samples were then reheated to austenitize them at 900°C to 1000°C. This can be done in about 30 minutes. It is then furnace cooled to a temperature of 190°C to 260°C and kept at this temperature for a period of 1 to 3 weeks, but if kept at a temperature of 300°C the maximum time is reduced to 2 weeks.

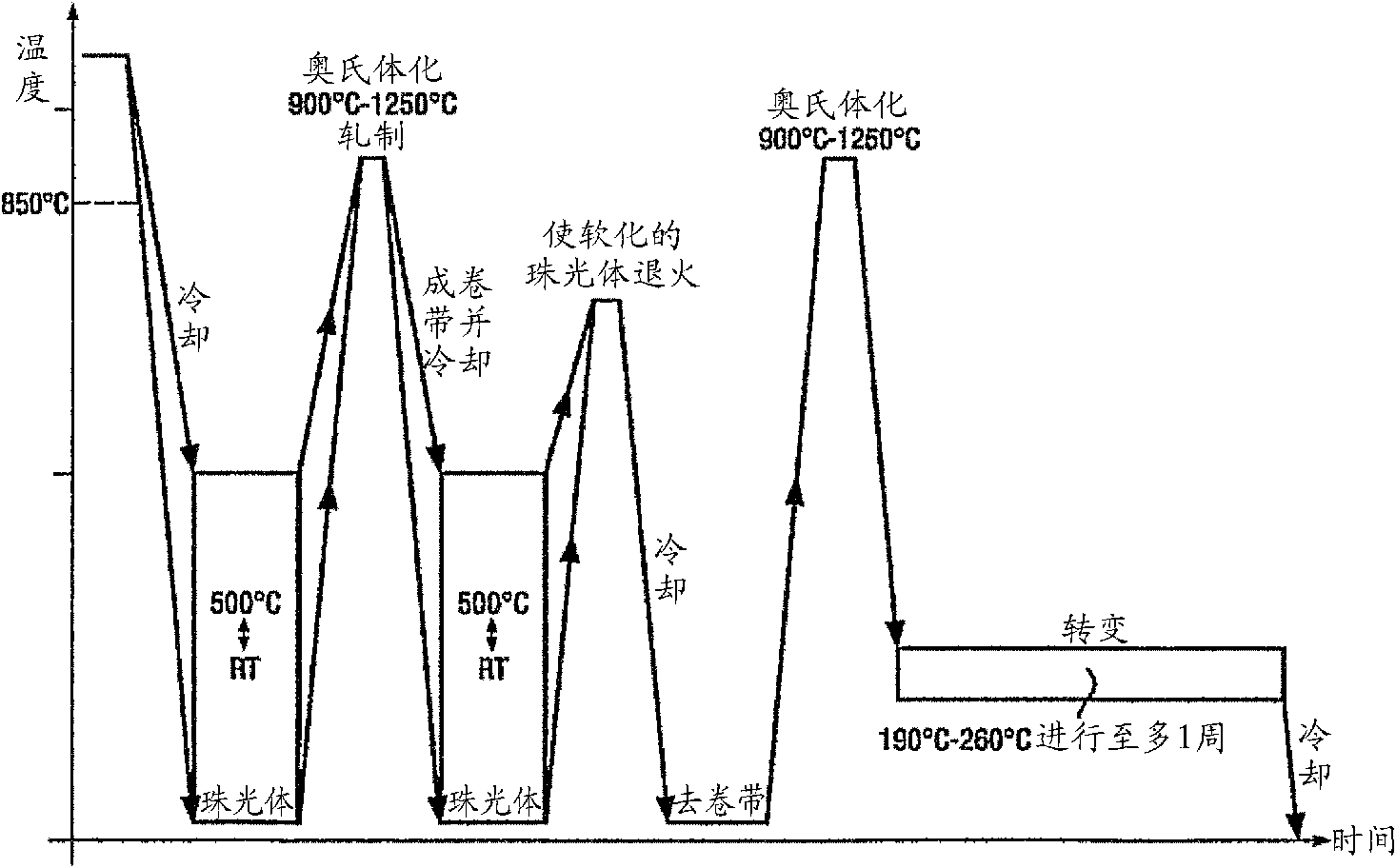

[0071] Figure 1B The fabrication process of the material of the present invention is shown, which will transform into pearlite with a relatively slow cooling process of about 2°C / min. However, it is believed that this is not a slow process, but one that is easily and economically accomplished in steel mills. Typically, during this production process, the steel can be cooled from a high temperature (above its austenitic transformation temperature) into larger slabs, usually stacked. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com