Control device for cutting failure single section of fixed multi-locomotive and control method of control device

A technology for reconnecting locomotives and fault removal, which is applied in the direction of electrical equipment, electric vehicles, vehicle parts, etc., can solve problems that affect transportation and cannot remove faulty vehicles, so as to improve transportation capacity, avoid machine failures, and achieve considerable economic benefits. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

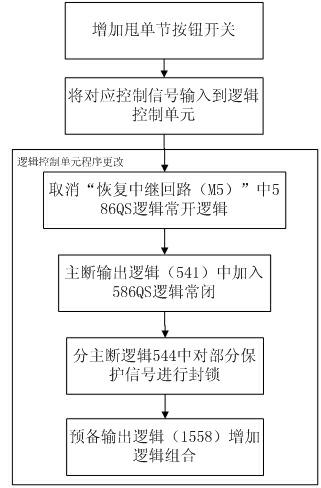

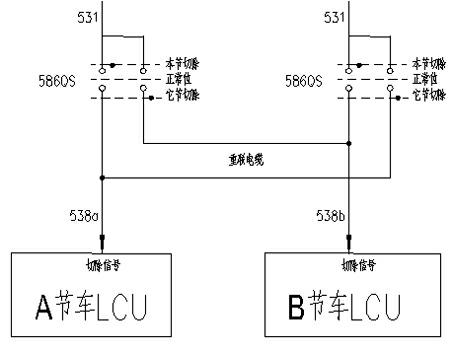

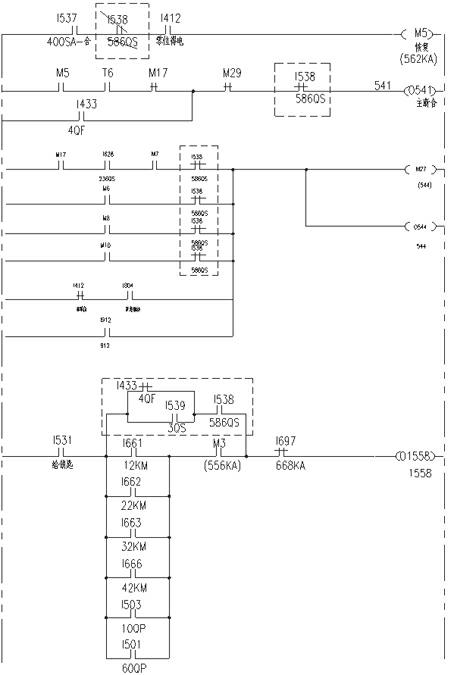

[0029] A single-section fault removal control device for fixed multi-line locomotive, such as figure 1 As shown, a single-section cutting control switch 586QS is installed on the driver’s desk of each car. The single-section cutting control switch 586QS of each car is equipped with three gears of this section, normal position, and other section. The output ends of the control signal 538a and 538b of the section cut-off control switch 586QS are respectively connected to the input end of the logic control unit LCU of the corresponding single vehicle. The output end of the switching signal I539 of the high voltage isolation switch 3QS of each single vehicle is connected to the output end of the corresponding single vehicle. The input terminal of the logic control unit LCU is connected.

[0030] The device of the present invention cancels the normally open logic of the single-section cut-off control switch 586QS in the restoration relay circuit M5, and ensures that the restoration rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com